Gases, Liquids, Vapors

advertisement

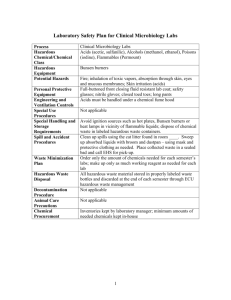

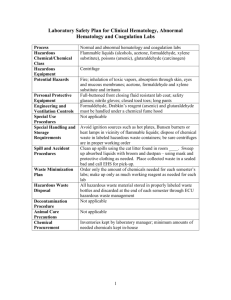

Intermec Solutions for Hazardous Environments: CK32IS Global Considerations Global Certification requirements UL ATEX IEC (Underwriters Laboratory) (European Atmospheres Explosibles Directives) (International Electrotechnical Commission) U.S. Canada Mexico European Union Austria Belgium Bulgaria Cyprus Czech Republic Denmark Estonia Finland France Germany Greece Hungary Ireland Italy Latvia Lithuania Luxembourg Malta Netherlands Poland Portugal Romania Slovakia Slovenia Spain Sweden United Kingdom of Great Britain and Northern Ireland Australia Singapore Malaysia Philippines Indonesia Saudi Arabia Norway Switzerland Turkey Slide 2 Global Reach Hazardous Environment Certifications UL, ATEX, IEC Localized Languages English, Spanish, French, German, Italian, Simplified Chinese, Traditional Chinese, Korean, Thai (character set only) RoHS Compliance Restriction of the Use of Certain Hazardous Substance in Electrical and Electronic Equipment WEEE Compliance Waste Electrical and Electronic Equipment RF Certifications Support & Service Certified repairs at all service centers worldwide Slide 3 Hazardous Certifications UL ATEX IEC (Underwriters Laboratory) (European Atmospheres Explosibles Directives) (International Electrotechnical Commission) Gases, Liquids, Vapors Class I Division 1 Group A,B,C,D (T4) Class 1 Zone 0 Group IIC (T4) Gases, Liquids, Vapors Zone 0 (T4) Group IIC Gases, Liquids, Vapors Zone 0 (T4) Group IIC Dusts & Fibers Class II Division 1 Groups E, F and G Class III Division 1 Dusts & Fibers Zone 20 Group II* T250°C Dusts & Fibers Zone 20 Group II* T250°C Underground Mining Group I M1 Underground Mining Group I M1 * Except conductive dust Slide 4 Hazardous Certifications From concept, design specifications dedicated to meeting customer’s most stringent requirements for flammable gases, vapors, liquids, dusts or fibers. UL ATEX IEC (Underwriters Laboratory) (European Atmospheres Explosibles Directives) (International Electrotechnical Commission) Gases, Liquids, Vapors Class I Division 1 Group A,B,C,D (T4) Class 1 Zone 0 Group IIC (T4) Gases, Liquids, Vapors Zone 0 (T4) Group IIC Gases, Liquids, Vapors Zone 0 (T4) Group IIC Dusts & Fibers Class II Division 1 Groups E, F and G Class III Division 1 Dusts & Fibers Zone 20 Group II* T250°C Dusts & Fibers Zone 20 Group II* T250°C Underground Mining Group I M1 Underground Mining Group I M1 * Except conductive dust Slide 5 High Level Device Requirements Chemical, Oil & Gas, and Pharmaceutical customers told us their “ideal” requirements: One Device - Globally One Manufacturer - Globally Long Product Life Cycle Industry Commitment - Globally Global Technical Support & Service Slide 6 Detailed Device Requirements – Typical Customer Device: Windows mobile PDA Hazardous Ratings: Memory: 802.11b/g Cisco CCX V3 radio support Bluetooth – Used to talk to peripherals (RFID, Vibration, Temperature probes) Keyboard/Ergonomics: 128 MB of RAM / 512 MB of Flash Storage Communications: 60% - UL Class 1 Div 2 for North America 5% - UL Class 1 Div 1 for North America 20% - ATEX Zone 2 for Europe 5% - ATEX Zone 1 for Europe 10% - IEC, Rest of World (RoW) Big, easy to use Arrows & Numeric Keys (for use in gloved environments) User installable Trigger Handle Support: 8 Hours of Battery Life No loss of data/application after cold boot Global Support Lock Down Application Slide 7 Detailed Device Requirements – What are yours? Device? Hazardous Ratings? Memory? Communications? Keyboard/Ergonomics? Support? Slide 8 Enterprise Asset Management Solutions Example: Plant Maintenance & Repair Trend Key Issues Good maintenance and support practices are an integral component of optimized production processes and lean manufacturing. Manufacturers are focused on improving the efficiency of production. As production capacity rises above 80% utilization, efficiency and productivity in plant maintenance and repair is mandatory. Return on Assets (ROA) is becoming the primary driver of equipment investment. Solutions In-premise and extra-premise predictive maintenance. Break-Fix operations. Dispatching for optimized production. Operator directed response (ODR). Slide 9 Intermec Hazardous Environment Solutions 751 Class I Div 2 751 ATEX Zone 2 CK31 Class I Div 2 730 Class I Div 1 CK61 Class I Div 2 CK32IS Slide 10 Intermec Hazardous Environment Solutions 751 Class 1 Div 2 751 ATEX Zone 2 730 Class 1 Div 1 CK61 Class1 Div 2 CK31 Class 1 Div 2 CK32IS Intermec Solutions Family Mobile Computers Fixed Mount Computers RFID Scanners Printers Slide 11 CK32 Intrinsically Safe Mobile Computer CK32IS Features Windows Mobile 5.0 Premium & Phone Edition & MSFP 802.11b/g WLAN w/ CCX 3, USB Bluetooth & Ethernet Intel XScale PXA270 Processor Intermec Linear Imager QVGA Color Display w/ Touchscreen 42 or 56 Keypad options (Standard, 3270/5250, VT/ANSI) 128 MB RAM 512 MB Persistent Storage Integrated Speaker/microphone Slide 13 CK32IS Usability User installable trigger handle Batteries removable in hazardous environments Keypad options support gloved use Slide 14 CK32IS Accessories Communication Adapter* Battery Pack Option Quad Battery Charger* Trigger Handle User Installable Carrying Strap USB Client and Ethernet Battery Eliminator Leather Hand Strap Screen Protector Kit Tethered Stylus Kit * Associated Apparatus Certified – Guarantees that any outside equipment cannot damage the unit. Not for use in Hazardous environments. Slide 15 CK32IS Durability Designed from inception for exceptional durability 5 foot drop specification IP67 sealed Operating temperature: -20°C to +50°C Robust construction: Electrostatic Dissipation Internal Antennas Hard Plastic Key tops Polycarbonate Enclosure Internal Magnesium Frame Internal Shock Mounting Encapsulated Circuit Boards Slide 16 Hardware Durability Internal Magnesium Frame Thicker than comparable frame in standard product Lightweight but strong Internal skeleton Slide 17 Hardware Durability Magnesium frame Reduces flexing, risk of damage Maintains relative alignment and spacing Protects LCD display glass Slide 18 Hardware Durability Encapsulated Circuit Boards High temperature silicon for thermal insulation Second line of protection against gas & dust Protects components from shock, vibration, corrosion Slide 19 Hardware Durability Internal Shock Mounting Isolates electronic modules Display Slide 20 Hardware Durability Hard Plastic Key Caps Laser engraved Silicon Keypad Touch Screen Touch Screen Protector Slide 21 Hardware Durability Polycarbonate Enclosure Extra thick, high quality, reinforced Conductive IP67-rated seal Modular construction Slide 22 Worldwide Service & Support More than 70 service & support facilities Local languages, time zones Medallion service contracts Tel and web based post sales support Intermec Repair Locations Intermec Global Service Partners Slide 23 CK32IS Hazardous Certifications Certified Intrinsically Safe by ALL 3 global agencies, for gases, vapors, liquids, dusts, fibers and underground mining. Today’s safety requirements. And tomorrow’s. UL ATEX IEC (Underwriters Laboratory) (European Atmospheres Explosibles Directives) (International Electrotechnical Commission) Gases, Liquids, Vapors Class I Division 1 Group A,B,C,D (T4) Class 1 Zone 0 Group IIC (T4) Gases, Liquids, Vapors Zone 0 (T4) Group IIC Gases, Liquids, Vapors Zone 0 (T4) Group IIC Dusts & Fibers Class II Division 1 Groups E, F and G Class III Division 1 Dusts & Fibers Zone 20 Group II* T250°C Dusts & Fibers Zone 20 Group II* T250°C Underground Mining Group I M1 Underground Mining Group I M1 * Except conductive dust Slide 24 Designed to Deliver Highest Level of Safety Full International Safety Certifications in One Computer Meets or Exceeds Latest Safety Standards: Zone 0 Exceptionally Rugged: 5’ drop, IP67 Worldwide Service & Support Slide 25 Next Steps Compliance: Configuration: Define your safety certification requirements Determine detailed device requirements Service & Support: Determine global needs Slide 26 Thank you! ADC Nordic - Distributor in the Nordic countries Phone +46 40-680 02 80 Slide 27