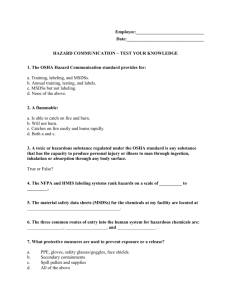

Hazard Communication Standard

advertisement

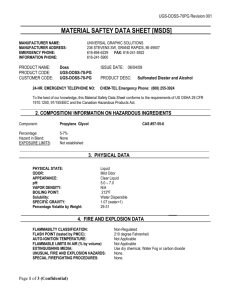

Hazard Communication (Employee Right-to-Know) AEE Safety Training Program 2008 Employee Right-to-Know OSHA’s Hazard Communication Standard (HCS) is based on a simple concept—that employees have both a need and a right to know the hazards and identities of the chemicals they are exposed to when working. They also need to know what protective measures are available to prevent adverse effects from occurring. OSHA designed the HCS to provide employees with the information they need to know. The HCS standard’s common name is “Employee Right-to-Know” Purpose & Scope In order to ensure chemical safety in the workplace, information must be available about the identities and hazards of the chemicals. OSHA's Hazard Communication Standard (HCS) requires the development and dissemination of such information: Chemical manufacturers and importers are required to evaluate the hazards of the chemicals they produce or import, and Prepare labels and material safety data sheets (MSDSs) to convey the hazard information to their downstream customers. All employers with hazardous chemicals in their workplaces must have labels and MSDSs for their exposed workers, and train them to handle the chemicals appropriately. Four Major Elements of the Program Material Safety Data Sheets (MSDS) and Inventory of Chemicals Labels Written Program Training Implementation Office Locations: Implementation of this program is the responsibility of the local management (Unit Manager, Laboratory Manager, Office Manager) Field Activities: Implementation of this program is the responsibility of the Project Manager. Hazardous Material Inventory Maintain a hazardous material inventory that lists all of the hazardous materials used at each workplace (i.e., office/lab/field location). Use chemical names consistent with the applicable MSDS's. 2. File a copy of the chemical inventory with the Project Safety Plan or with the Health and Safety Coordinator. 1. Material Safety Data Sheets (MSDS's) 1. 2. 3. 4. 5. 6. Obtain a MSDS for each chemical before it is used. Review each MSDS when it is received to evaluate whether the information is complete and to determine if existing protective measures are adequate. Maintain a collection of all applicable and relevant MSDS's where they are accessible at all times. Replace MSDS sheets when updated sheets are received (or at least every 3 years). Communicate any significant changes to those who work with the chemical. MSDS's are required for all hazardous materials used on site by project personnel. Labels Unless each container has appropriate labeling, label all chemical containers with: 1. 2. 3. Identity of the hazardous chemical(s), Appropriate hazard warnings, and Name and address of the chemical manufacturer, importer, or other responsible party. Hazardous Non-routine Tasks Periodically, employees are required to perform hazardous non-routine tasks. Prior to starting work on such projects, provide each employee with information about hazards to which they may be exposed during such an activity. This information will include: Specific chemical hazards. Protective/safety measures which must be utilized. Measures that have been taken to lessen the hazards including ventilation, respirators, presence of another employee and emergency procedures. Informing Contractors/Subcontractors Provide contractors/subcontractors the following information on chemicals used by or provided to AEE personnel: 1. 2. 3. Names of hazardous chemicals to which they may be exposed while on the jobsite. Precautions the employees may take to lessen the possibility of exposure by usage of appropriate protective measures. Location of MSDS’s and written chemical inventory. HAZCOM Training Conduct training of all employees potentially exposed to hazardous materials on the following schedule: Before new employees begin their jobs. Whenever new chemicals are introduced into the workplace, or Annually thereafter. Document both online and site-specific training Content of This Online Training HAZCOM program Compliance checklist Applicable regulatory requirements Labeling Chemical inventory How to read an MSDS Content of Site-Specific Training Names of those responsible for implementing this program. Unit manager Lab Manger Project Manager SHE Coordinator Location of the program, chemical inventory and MSDS's. Chemicals used locally, their hazards (chemical & physical). Safe work practices using chemicals. Checklist for Compliance Obtained a copy of the OSHA Standard. Read and understood the requirements. 3. Assigned responsibility for tasks. 4. Prepared an inventory of chemicals. 5. Ensured containers are labeled. 6. Obtained MSDS for each chemical. 7. Prepared written program. 8. Made MSDSs available to all workers. 9. Conducted training of workers. 10. Established procedures to maintain current program. 11. Established procedures to evaluate effectiveness. 1. 2. Checklist for Compliance – 1 & 2 Obtain a copy of the standard. Safety Coordinators, Unit, Laboratory and Office Managers should print and review a copy of OSHA Hazard Communication Standard 29 CFR 1910.1200 1910.1200, Hazard communication Appendix A, Health hazard definitions (Mandatory) Appendix B, Hazard determination (Mandatory) Appendix C, Information sources (Advisory) Appendix D, Definition of "trade secret" (Mandatory) Appendix E, Guidelines for employer compliance (Advisory) OSHA Document 3111 (2000) Hazard Communication Guidelines for Compliance http://osha.gov/Publications/osha3111.pdf GUIDANCE FOR HAZARD DETERMINATION FOR COMPLIANCE WITH THE OSHA HAZARD COMMUNICATION STANDARD (29 CFR 1910.1200) http://osha.gov/dsg/hazcom/ghd053107.html Read and understand the requirements. Checklist for Compliance - 3 Assign responsibility for tasks at the local level. Local management (unit manager, office manager, laboratory manager) are responsible for the overall implementation of the hazard communication program Corporate Safety Department provides coordination, company-wide policy, generic company-wide training, and monitors compliance with the program Qualified Local Safety Coordinators or designated H&S professionals are responsible for local implementation of the program and site-specific training Designated employees are responsible for particular program elements such as chemical inventory development and labeling (should be appointed by the local management) Checklist for Compliance - 4 Prepare an inventory of chemicals Date Location Chemical name/product name Quantity Is it labeled? Do you have MSDS? Prepare an inventory of chemicals Any hazardous material in any quantity on AEE property or sites will be identified on a list by the SHE Coordinator (for office locations), SHSC (for sites), supervisor (for work areas), or designee. The information on the list includes the substance name (as referenced on the MSDS), storage location, and quantity. The inventory may be compiled for the workplace as a whole or for individual work areas. The inventory will be updated quarterly, or more frequently, as necessary. Checklist for Compliance - 5 Ensure containers are labeled "... the employer shall ensure that each container of hazardous chemicals in the work place is labeled, tagged or marked with... (i) Identity of the hazardous chemicals...and (ii) Appropriate hazard warnings, or alternatively, words, pictures, symbols or combination thereof,...to...provide the employees with the specific information regarding the physical and health hazards of the hazardous chemicals." Example of acceptable label ISOPROPYL ALCOHOL (2 - Propanol) FLAMMABLE LIQUID ABC Chemical Co. 123 Main St. City, State Zip Ensure containers are labeled Employees and contractors will be informed that they should check all incoming hazardous material container labels for the following information: identity of product appropriate hazard warning name and address of chemical manufacturer, importer, or other responsible party Labels must be legible and prominently displayed. No existing label will be removed or defaced on containers of hazardous materials. NFPA 704 Hazard Identification System The National Fire Protection Agency (NFPA), in section 704 of the National Fire Code, specifies a system for identifying the hazards associated with materials. Although the system was developed primarily with the needs of fire protection agencies in mind, it is of value to anyone who needs to handle potentially hazardous material. The hazard identification signal is a color-coded array of four numbers or letters arranged in a diamond shape. You will see hazard diamonds like this on trucks, storage tanks, bottles of chemicals, and in various other places. The blue, red, and yellow fields (health, flammability, and reactivity) all use a numbering scale ranging from 0 to 4. A value of zero means that the material poses essentially no hazard; a rating of four indicates extreme danger. The fourth value (associated with white) tends to be more variable, both in meaning and in what letters or numbers are written there. NFPA Diamond HMIG -- Hazardous Material Identification Guide HMIS -- Hazardous Material Information System The OSHA Hazard Communication Standard (HCS) requires all chemicals in the workplace to be labeled in a manner that warns of any hazards the chemical may present. The actual format and method of labeling is not specified, so there are several different formats in use. The NFPA hazard diamond is one such method. Two other HCS compliance systems that are very similar to one another are described here. The Hazardous Material Identification Guide (HMIG) is a labeling system developed and sold through Lab Safety Supply Inc. The Hazardous Material Information System (HMIS) is a labeling system developed by the National Paint and Coatings Association (NPCA) and sold through Labelmaster Inc. Both systems use a label with four color bars and a space at the top where the name of the chemical should be written (see figure this page). The blue, red, and yellow colored bars indicate, respectively, the health, flammability, and reactivity hazard associated with the material. These three bars use a numbering scale ranging from 0 to 4. A value of zero means that the material poses essentially no hazard; a rating of four indicates extreme danger. Although the details of how numbers are assigned may vary somewhat between systems, this is essentially the same overall scheme as is used in the NFPA system. (But see also the note on differences between NFPA and HMIG.) The fourth, white bar is marked "protective equipment" in the HMIG system, and "personal protection" in the HMIS system. Both systems (HMIG and HMIS) place a letter in this bar to indicate the kind(s) of personal protective equipment (PPE) that should be used in order to handle the material safely. The letters used are A - K and X. Meanings of the letters are the same in both systems, and both systems augment the letter code with icons or pictograms showing the kinds of PPE to be used. A significant difference between the HMIG and HMIS systems is that the 1995 revised HMIS system includes a second box on the blue (health hazard) bar. If this second box holds an asterisk (*), then the health hazard associated with the material is a chronic (long-term) effect. HMIG Labels HMIG Label Similarities and Differences between NFPA and HMIS Both the NFPA Hazard Identification System and the Hazardous Material Identification Guide (HMIG or HMIS) may be used to comply with the labeling requirement of the OSHA Hazard Communication Standard (HCS). These systems, although similar, differ in some important respects. Similarities Both systems have three color-coded fields to indicate the flammability (red), health (blue), and reactivity (yellow) hazards associated with the material. Both use a system of five numbers, ranging from 0 to 4, to indicate the severity of hazard, with 0 being the least and 4 being the most hazardous. Differences They differ in layout -- NFPA uses four diamonds, HMIG uses vertically stacked bars. The differ in interpretation of the fourth, white field (special handling in the NFPA system; protective equipment in the HMIG system). Possibly the most significant difference, however, has to do with the intended audience for each of the systems. The HMIG (or HMIS) was devised as an HCS compliance tool, and has employees who must handle hazardous chemicals in the workplace as the intended audience. The NFPA system was designed to alert fire fighters arriving on the scene of a fire to the hazards associated with materials present at that location. Therefore, the numbers assigned in the NFPA system assume that a fire is present. No such assumption holds in the HMIG/HMIS system. For this reason, the numbers that are assigned to the flammability, health, and reactivity hazards may differ between the NFPA and HMIG systems, even for the exact same chemical. NFPA and HMIG Labels NFPA and HMIG labels can be obtained, for example, from http://www.labsafety.com/store/Signs__Labels_-_Tapes/Labels/RTK__Chemical_Labels/60373/ or http://www.shippinglabels.com/RTK/chemical_la bels.asp or generated internally Write On HMIG Labels Can be Obtained from Labsafety.com Use HMIG Write-On Labels to identify hazard ratings quickly and easily on containers in your workplace. Two sizes of self-adhesive paper Labels help you warn workers about dangers. Small Labels have room for you to write in the chemical name, manufacturer, date and rating. Large Labels allow you to add all the same information as the Small Labels plus room for the common name. Roll of 1000. http://www.labsafety.com/store/Signs_-_Labels__Tapes/Labels/RTK_-_Chemical_Labels/60373/ Checklist for Compliance - 6 Obtain MSDS for each chemical Manufacturers/suppliers are required by law to provide a copy of MSDS for every product You probably can find your MSDS on the Internet All MSDSs in your inventory should be less then three years old A separate section of this training is dedicated to reading and understanding MSDSs Checklist for Compliance – 7, 8 Prepare written HSC program. Made MSDSs available to all workers. At AEE written HSC program is included in SHE Volume VI, SOP H-8 Hazard Communication Written Program (this link is to the intranet site and will not work outside of restricted AEE network) Please note that this program needs to be locally customized at every location to include NAMES of local responsible parties Written program and MSDS should be placed in Right-to-Know Center easily accessible by all employees; various options for RTK Centers are listed here http://www.labsafety.com/store/Signs_-_Labels__Tapes/Right-to-Know_-_RTK/RTK_Information_Stations/ Field HASPs should include a section on HSC and all MSDS for all chemicals to be used in the field Checklist for Compliance – 9, 10, 11 Conduct training of workers. Establish procedures to maintain current program. Establish procedures to evaluate effectiveness The following portion of this training is dedicated to reading and understanding MSDS Please make sure that our HSC program is active, employees are trained, chemicals are labeled, MSDS are current and available to all employees and subcontractors The Corporate Safety Department will continue auditing our programs and making sure they are effective Understanding MSDS for OSHA Hazard Communication and WHMIS Training AEE Training Program 2008 Understanding MSDS The information provided in this presentation supplements Canadian WHMIS and the US Hazard Communication training Typical MSDS is reviewed using acetone as an example This detailed approach should be used when providing chemical-specific part of the training. Each MSDS for ALL products used by every employee should be reviewed and discussed in details Emergency response planning for incidental exposure, including availability of FA/CPR trained personnel, first aid stations, eye wash stations, emergency showers, and proper storage and use requirements should be included as well as spill response planning OSHA Recommended Format for Material Safety Data Sheets (MSDSs) In 1985, US Occupational Safety & health Administration (OSHA) established a voluntary format for MSDSs (OSHA Form 174) to assist manufacturers and importers who desired guidance on organizing MSDS information. When completed correctly, an MSDS prepared using Form 174 contains all of the information required by OSHA Hazard Communication Standard (29CFR1910.1200). However, Form 174 does not use the more organized and comprehensive 16-section format. …more from http://www.osha.gov/dsg/hazcom/msdsformat.html Minimum MSDS Content – Form 174 1. 2. 3. 4. 5. 6. 7. 8. Identity Hazardous Ingredients Physical/Chemical Characteristics Fire and Explosion Hazard Data Reactivity Data Health Hazard Data Precautions for Safe Handling and Use Control Measures OSHA Form 174 – Sections 1, 2 OSHA Form 174 – Section 3, 4, 5 OSHA Form 174 – Section 6 OSHA Form 174 – Section 7, 8 ANSI 16-section MSDS Format OSHA believes that use of a consistent format will improve the effectiveness of MSDSs by making information easier for the reader to find, regardless of the supplier of the MSDS. Because the 16-section format is accepted by consensus as the most appropriate format, OSHA no longer endorses that Form 174 be used for the preparation of MSDSs. Use of Form 174, however, is still acceptable under the HCS if it is completed correctly. ANSI 16-section MSDS Format In order to promote consistent presentation of information, OSHA now recommends that MSDSs follow the 16-section format established by the American National Standards Institute (ANSI) standard for preparation of MSDSs (Z400.1). By following this recommended format, the information of greatest concern to workers is featured at the beginning of the data sheet, including information on chemical composition and first aid measures. More technical information that addresses topics such as the physical and chemical properties of the material and toxicological data appears later in the document. While some of this information (such as ecological information) is not required by the OSHA Hazard Communication Standard (HCS), the 16-section MSDS is becoming the international norm. ANSI 16-section MSDS Format 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Manufacturer and supplier identification, Contact information Hazard(s) identification Composition/information on ingredients First-aid measures Fire-fighting measures Accidental release measures Handling and storage Exposure controls/personal protection Physical and chemical properties Stability and reactivity Toxicological information Ecological information Disposal considerations Transport information Regulatory information Other information Section 1: Chemical Product and Company Identification This section links the chemical name on the label to the MSDS. The MSDS also lists the name, address and the phone number of the company, manufacturer or distributor who provides the chemical. Example: Acetone Product Identification Synonyms: Dimethylketone; 2-propanone; dimethylketal CAS No.: 67-64-1 Molecular Weight: 58.08 Chemical Formula: (CH3)2CO Product Codes: J.T. Baker: 5008, 5018, 5356, 5580, 5965, 5975, 9001, 9002, 9003, 9004, 9005, 9006, 9007, 9008, 9009, 9010, 9015, 9024, 9036, 9125, 9254, 9271, A134, V655 Mallinckrodt: 0018, 2432, 2435, 2437, 2438, 2440, 2443, 2850, H451, H580, H981 Section 2: Composition/Information on Ingredients This section must identify all the hazardous ingredients of the material. For example, Ingredient - Acetone CAS 67-64-1 Percent 99 - 100% Hazardous – Yes Section 2: Composition/Information on Ingredients MSDS should list the chemical components as follows (1910.1200(g)(2)(i)(C)(1)): The chemical and common name(s) of all ingredients which have been determined to be health hazards, and which comprise 1% or greater of the composition, except that chemicals identified as carcinogens shall be listed if the concentrations are 0.1% or greater Section 3: Hazards Identification This section discusses the health and safety hazards of the product. The section may include safety ratings of the material, safe storage guidelines, PPE recommended to handle the material, and potential health effects by the route of entry Section 3: Hazards Identification Emergency Overview DANGER! EXTREMELY FLAMMABLE LIQUID AND VAPOR. VAPOR MAY CAUSE FLASH FIRE. HARMFUL IF SWALLOWED OR INHALED. CAUSES IRRITATION TO SKIN, EYES AND RESPIRATORY TRACT. AFFECTS CENTRAL NERVOUS SYSTEM. NFPA Ratings Health Rating: 2 – Moderate Flammability Rating: 3 - Severe (Flammable) Reactivity Rating: 0 - None Contact Rating: 3 - Severe Lab Protective Equip: GOGGLES & SHIELD; LAB COAT & APRON; VENT HOOD; PROPER GLOVES; CLASS B EXTINGUISHER Storage Color Code: Red (Flammable) Section 3: Hazards Identification Potential Health Effects Inhalation: Inhalation of vapors irritates the respiratory tract. May cause coughing, dizziness, dullness, and headache. Higher concentrations can produce central nervous system depression, narcosis, and unconsciousness. Ingestion: Swallowing small amounts is not likely to produce harmful effects. Ingestion of larger amounts may produce abdominal pain, nausea and vomiting. Aspiration into lungs can produce severe lung damage and is a medical emergency. Other symptoms are expected to parallel inhalation. Skin Contact: Irritating due to defatting action on skin. Causes redness, pain, drying and cracking of the skin. Eye Contact: Vapors are irritating to the eyes. Splashes may cause severe irritation, with stinging, tearing, redness and pain. Chronic Exposure: Prolonged or repeated skin contact may produce severe irritation or dermatitis. Aggravation of Pre-existing Conditions: Use of alcoholic beverages enhances toxic effects. Exposure may increase the toxic potential of chlorinated hydrocarbons, such as chloroform, trichloroethane. Section 4: First Aid Measures This section lists very basic first aid procedures for all routes of entry such as: Inhalation: Remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Get medical attention. Ingestion: Aspiration hazard. If swallowed, vomiting may occur spontaneously, but DO NOT INDUCE. If vomiting occurs, keep head below hips to prevent aspiration into lungs. Never give anything by mouth to an unconscious person. Call a physician immediately. Skin Contact: Immediately flush skin with plenty of water for at least 15 minutes. Remove contaminated clothing and shoes. Get medical attention. Wash clothing before reuse. Thoroughly clean shoes before reuse. Eye Contact: Immediately flush eyes with plenty of water for at least 15 minutes, lifting upper and lower eyelids occasionally. Get medical attention. Section 5: Fire Fighting Measures Fire: Flash point: -20C (-4F) CC Autoignition temperature: 465C (869F) Flammable limits in air % by volume: LEL: 2.5; UEL: 12.8 Extremely Flammable Liquid and Vapor! Vapor may cause flash fire. Explosion: Above flash point, vapor-air mixtures are explosive within flammable limits noted above. Vapors can flow along surfaces to distant ignition source and flash back. Contact with strong oxidizers may cause fire. Sealed containers may rupture when heated. This material may produce a floating fire hazard. Sensitive to static discharge. Fire Extinguishing Media: Dry chemical, alcohol foam or carbon dioxide. Water may be ineffective. Water spray may be used to keep fire exposed containers cool, dilute spills to nonflammable mixtures, protect personnel attempting to stop leak and disperse vapors. Special Information: In the event of a fire, wear full protective clothing and NIOSH-approved self-contained breathing apparatus with full facepiece operated in the pressure demand or other positive pressure mode. Section 6: Accidental Release Measures Ventilate area of leak or spill. Remove all sources of ignition. Wear appropriate personal protective equipment as specified in Section 8. Isolate hazard area. Keep unnecessary and unprotected personnel from entering. Contain and recover liquid when possible. Use nonsparking tools and equipment. Collect liquid in an appropriate container or absorb with an inert material (e. g., vermiculite, dry sand, earth), and place in a chemical waste container. Do not use combustible materials, such as saw dust. Do not flush to sewer! If a leak or spill has not ignited, use water spray to disperse the vapors, to protect personnel attempting to stop leak, and to flush spills away from exposures. US Regulations (CERCLA) require reporting spills and releases to soil, water and air in excess of reportable quantities. The toll free number for the US Coast Guard National Response Center is (800) 424-8802. J. T. Baker SOLUSORB® solvent adsorbent is recommended for spills of this product. Section 7: Handling and Storage Protect against physical damage. Store in a cool, dry wellventilated location, away from any area where the fire hazard may be acute. Outside or detached storage is preferred. Separate from incompatibles. Containers should be bonded and grounded for transfers to avoid static sparks. Storage and use areas should be No Smoking areas. Use non-sparking type tools and equipment, including explosion proof ventilation. Containers of this material may be hazardous when empty since they retain product residues (vapors, liquid); observe all warnings and precautions listed for the product. Section 8: Exposure Control and Personal Protection Airborne Exposure Limits: Acetone: OSHA Permissible Exposure Limit (PEL): 1000 ppm (TWA) ACGIH Threshold Limit Value (TLV): 500 ppm (TWA), 750 ppm (STEL) A4 - not classifiable as a human carcinogen Ventilation System: A system of local and/or general exhaust is recommended to keep employee exposures below the Airborne Exposure Limits. Local exhaust ventilation is generally preferred because it can control the emissions of the contaminant at its source, preventing dispersion of it into the general work area. Please refer to the ACGIH document, Industrial Ventilation, A Manual of Recommended Practices, most recent edition, for details. Personal Respirators (NIOSH Approved): If the exposure limit is exceeded and engineering controls are not feasible, a half-face organic vapor respirator may be worn for up to ten times the exposure limit, or the maximum use concentration specified by the appropriate regulatory agency or respirator supplier, whichever is lowest. A full-face piece organic vapor respirator may be worn up to 50 times the exposure limit, or the maximum use concentration specified by the appropriate regulatory agency or respirator supplier, whichever is lowest. For emergencies or instances where the exposure levels are not known, use a full-face piece positive-pressure, air-supplied respirator. WARNING: Air-purifying respirators do not protect workers in oxygen-deficient atmospheres. Skin Protection: Wear impervious protective clothing, including boots, gloves, lab coat, apron or coveralls, as appropriate, to prevent skin contact. Eye Protection: Use chemical safety goggles and/or a full face shield where splashing is possible. Maintain eye wash fountain and quick-drench facilities in work area. Section 8: Understanding Airborne Exposure Limits Airborne Exposure Limits: Acetone: OSHA Permissible Exposure Limit (PEL): 1,000 ppm (TWA) ACGIH Threshold Limit Value (TLV): 500 ppm (TWA), 750 ppm (STEL) A4 - not classifiable as a human carcinogen What is permissible exposure limit (PEL) and threshold limit value (TLV)? OSHA PELs are based on the numbers developed by the American Conference of Governmental Industrial Hygienists (ACGIH) at the time when the OSHA standard 1910.1000 was finalized. These numbers are rarely updated. They are represent mandatory value to comply with in the US. Current ACGIH TLV numbers (updated annually) represent the best management practice and standard of care. Accepted as a standard in some jurisdictions in the US, Canada and around the Globe. Three categories of TLV are specified by the ACGIH: Threshold Limit Value – Time Weighted Average (TLV – TWA) Threshold Limit Value – Short Term Exposure Limit (STEL) Threshold Limit Value – Ceiling (C) Section 8: Understanding Airborne Exposure Limits Threshold Limit Value – Time Weighted Average (TLV – TWA) Threshold Limit Value – Short Term Exposure Limit (STEL) A STEL is defined as a 15-minute TWA exposure which should not be exceeded at any time during a workday. Exposures to STEL should be no longer than 15-minutes and no more than 4 times a day. Threshold Limit Value – Ceiling (C) The time weighted concentration for a normal 8-hour workday and a 40hour workweek, to which nearly all workers may be repeatedly exposed, day after day, without adverse effect The concentration that should not be exceeded during any part of working exposure OSHA Permissible Exposure Limit utilizes similar but slightly different conditions Section 8: Understanding Airborne Exposure Limits TLVs for gases and vapors are usually established in term of parts per million of substance in air by volume (ppm) They also, sometimes, listed in term of milligrams of substance per cubic meter of air (mg/m3) The conversion is based on 760 torr barometric pressure at 25oC (77oF, and where 24.45 = molar volume in liters, giving a conversion equation of: TLV, mg/m3 = TLV, ppm * (gram molecular weight of substance)/24.45 TLV, ppm = TLV, mg/m3 * 24.45/ (gram molecular weight of substance) Section 8: Understanding Airborne Exposure Limits Carcinogenicity A1 – confirmed human carcinogen A2 – suspected human carcinogen A3 – animal carcinogen A4 – not classifiable as human carcinogen A5 – not suspected as human carcinogen Section 8: Understanding Airborne Exposure Limits When reviewing your MSDSs, please note TLV or PELs and carcinogenicity notations Please talk to your regional or corporate SHE representative if you are working with a chemical with TLV < 25 ppm or with a chemical defined as A1-A3. Section 8: Understanding Airborne Exposure Limits OSHA PELs are listed in the tables Z1-Z3 of OSHA Standard 29CFR1910.1000 – Air Contaminants 1910.1000 1910.1000 1910.1000 1910.1000 - Air contaminants. TABLE Z-1 - TABLE Z-1 Limits for Air Contaminants. TABLE Z-2 - TABLE Z-2 TABLE Z-3 - TABLE Z-3 Mineral Dusts Section 9: Physical and Chemical Properties Appearance: Clear, colorless, volatile liquid. Odor: Fragrant, mint-like Solubility: Miscible in all proportions in water. Specific Gravity: 0.79 @ 20C/4C pH: No information found. % Volatiles by volume @ 21C (70F): 100 Boiling Point: 56.5C (133F) @ 760 mm Hg Melting Point: -95C (-139F) Vapor Density (Air=1): 2.0 Vapor Pressure (mm Hg): 400 @ 39.5C (104F) Evaporation Rate (BuAc=1): ca. 7.7 Section 10: Stability and Reactivity Stability: Stable under ordinary conditions of use and storage. Carbon dioxide and carbon monoxide may form when heated to decomposition. Hazardous Decomposition Products: Hazardous Polymerization: Incompatibilities: Will not occur. Concentrated nitric and sulfuric acid mixtures, oxidizing materials, chloroform, alkalis, chlorine compounds, acids, potassium t-butoxide. Conditions to Avoid: Heat, flames, ignition sources and incompatibles. Section 11: Toxicological Information Oral rat LD50: 5,800 mg/kg Inhalation rat LC50: 42 ppm NTP Carcinogen Ingredient Acetone (67-64-1) Known – No Anticipated – No IARC Category - None Section 11: Reading Toxicological Information Oral rat LD50: 5,800 mg/kg – what does this mean? LD50 – a median lethal dose a chemical that has a median lethal dose LD50 = 50 mg/kg when administered orally to rats is highly toxic a chemical with oral rat LD50 = 5,800 mg/kg is not considered very toxic Inhalation rat LC50: 42ppm - what does this mean? a chemical that has a median lethal concentration LC50 in air of 200 ppm or less of gas or vapor when administered by continuous inhalation for one hour to rats is highly toxic a chemical with inhalation rat LD50 = 42 ppm is considered very toxic Section 11: Reading Toxicological Information Hepatotoxins: Chemicals which produce liver damage Nephrotoxins: Chemicals which produce kidney damage Signs & Symptoms: Edema; proteinuria. Chemicals: Halogenated hydrocarbons; uranium Neurotoxins: Chemicals which produce their primary toxic effects on the nervous system Signs & Symptoms: Jaundice; liver enlargement Chemicals: Carbon tetrachloride; nitrosamines Signs & Symptoms: Narcosis; behavioral changes; decrease in motor functions Chemicals: Mercury; carbon disulfide Agents which act on the blood: Decrease hemoglobin function; deprive the body tissues of oxygen Signs & Symptoms: Cyanosis; loss of consciousness Chemicals: Carbon monoxide; cyanides Section 11: Reading Toxicological Information Agents which damage the lung: Chemicals which irritate or damage pulmonary tissue Reproductive toxins: Chemicals which affect the reproductive capabilities including chromosomal damage (mutations) and effects on fetuses (teratogenesis) Signs & Symptoms: Birth defects; sterility Chemicals: Lead; DBCP Cutaneous hazards: Chemicals which affect the dermal layer of the body Signs & Symptoms: Cough; tightness in chest; shortness of breath Chemicals: Silica; asbestos Signs & Symptoms: Defatting of the skin; rashes; irritation Chemicals: Ketones; chlorinated compounds Eye hazards: Chemicals which affect the eye or visual capacity Signs & Symptoms: Conjunctivitis; corneal damage Chemicals: Organic solvents; acids Section 12: Ecological Information Environmental Fate: When released into the soil, this material is expected to readily biodegrade. When released into the soil, this material is expected to leach into groundwater. When released into the soil, this material is expected to quickly evaporate. When released into water, this material is expected to readily biodegrade. When released to water, this material is expected to quickly evaporate. This material has a log octanol-water partition coefficient of less than 3.0. This material is not expected to significantly bioaccumulate. When released into the air, this material may be moderately degraded by reaction with photochemically produced hydroxyl radicals. When released into the air, this material may be moderately degraded by photolysis. When released into the air, this material is expected to be readily removed from the atmosphere by wet deposition. Environmental Toxicity: This material is not expected to be toxic to aquatic life. The LC50/96-hour values for fish are over 100 mg/l. Section 13: Disposal Considerations Whatever cannot be saved for recovery or recycling should be handled as hazardous waste and sent to a RCRA approved incinerator or disposed in a RCRA approved waste facility. Processing, use or contamination of this product may change the waste management options. State and local disposal regulations may differ from federal disposal regulations. Dispose of container and unused contents in accordance with federal, state and local requirements. Section 14: Transport Information Domestic (Land, D.O.T.) Proper Shipping Name: ACETONE Hazard Class: 3 UN/NA: UN1090 Packing Group: II Information reported for product/size: 188L International (Water, I.M.O.) Proper Shipping Name: ACETONE Hazard Class: 3 UN/NA: UN1090 Packing Group: II Information reported for product/size: 188L Section 15: Regulatory Information Chemical Inventory Status Federal, State & International Regulations TSCA – yes Canada DSL – yes Canada NDSL – yes SARA 302 RQ - no SARA 302 TRQ - no SARA 313 List – yes CERCLA – 5,000 lbs RCRA 261.33 – U002 TSCA 8(d) – no WHMIS: This MSDS has been prepared according to the hazard criteria of the Controlled Products Regulations (CPR) and the MSDS contains all of the information required by the CPR. Section 15: Reading Regulatory Information TSCA Inventory (US) EPA classifies chemical substances as either "existing" chemicals or "new" chemicals. The only way to determine if the substance you are working with is a new chemical is by consulting EPA's Toxic Substances Control Act Chemical Substance Inventory (commonly referred to as the TSCA Inventory or just the Inventory). Any substance that is not on the Inventory is classified as a new chemical. If a substance is "new", it can be manufactured for a commercial purpose only if it is subject to an exemption from PMN reporting or a TSCA reporting exclusion (for example, a Low Volume Exemption, or exclusion as a naturally-occurring material). For substances which are "existing", the Inventory can be used to determine if there are restrictions on manufacture or use under the Toxic Substances Control Act (TSCA) .There are approximately 75,000 chemical substances, as defined in Section 3 of the TSCA, on the Inventory at this time. Canada DSL/NDSL Inventory Canada's environmental inventory, the Domestic / Non-Domestic Substances List contains over 70,000 chemicals Section 15: Reading Regulatory Information SARA RQ, CERCLA RQ (US) Any release of one or more of the roughly 800 CERCLA or 360 Emergency Planning and Community Right-to-Know Act (EPCRA or SARA Title III) hazardous substances that equals or exceeds a reportable quantity (RQ) must be reported to the EPA National Response Center (NRC) in the US. RQs are adjusted to one of five levels: 1, 10, 100, 1,000, or 5,000 pounds. EPA bases adjustments to the RQs on the intrinsic characteristics of each hazardous substance, such as the aquatic toxicity, acute and chronic toxicity, ignitability, reactivity, and potential carcinogenicity. An RQ value is established for each of these characteristics of a hazardous substance, with the most stringent RQ value (i.e., the lowest quantity) becoming the final RQ or reporting trigger reporting for that hazardous substance spill or release. Section 15: Reading Regulatory Information What “RCRA 261.33 – U002” means? Acetone waste is classified as RCRA listed hazardous waste. By definition, EPA determined that some specific wastes are hazardous. These wastes are incorporated into lists published by the Agency. These lists are organized into three categories: The F-list (non-specific source wastes). This list identifies wastes from common manufacturing and industrial processes, such as solvents that have been used in cleaning or degreasing operations. Because the processes producing these wastes can occur in different sectors of industry, the F-listed wastes are known as wastes from nonspecific sources. Wastes included on the F-list can be found in the regulations at 40 CFR §261.31. The K-list (source-specific wastes). This list includes certain wastes from specific industries, such as petroleum refining or pesticide manufacturing. Certain sludges and wastewaters from treatment and production processes in these industries are examples of source-specific wastes. Wastes included on the K-list can be found in the regulations at 40 CFR §261.32. The P-list and the U-list (discarded commercial chemical products). These lists include specific commercial chemical products in an unused form. Some pesticides and some pharmaceutical products become hazardous waste when discarded. Wastes included on the P- and U-lists can be found in the regulations at 40 CFR §261.33. Hazardous Waste Listings - A User-Friendly Reference Document, Draft, March 2008 (PDF) (118 pp, 612K) Section 15: Reading Regulatory Information WHMIS: “This MSDS has been prepared according to the hazard criteria of the Controlled Products Regulations (CPR) and the MSDS contains all of the information required by the CPR.” Canadian authorities require a statement above be entered in the "Regulatory Information" section of every MSDS to be approved for use in Canada. Section 16: Other Information NFPA Ratings: Health: 1 Flammability: 3 Reactivity: 0 Label Hazard Warning: DANGER! EXTREMELY FLAMMABLE LIQUID AND VAPOR. VAPOR MAY CAUSE FLASH FIRE. HARMFUL IF SWALLOWED OR INHALED. CAUSES IRRITATION TO SKIN, EYES AND RESPIRATORY TRACT. AFFECTS CENTRAL NERVOUS SYSTEM. Label Precautions: Keep away from heat, sparks and flame. Keep container closed. Use only with adequate ventilation. Wash thoroughly after handling. Avoid breathing vapor. Avoid contact with eyes, skin and clothing. Label First Aid: Aspiration hazard. If swallowed, vomiting may occur spontaneously, but DO NOT INDUCE. If vomiting occurs, keep head below hips to prevent aspiration into lungs. Never give anything by mouth to an unconscious person. Call a physician immediately. If inhaled, remove to fresh air. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. In case of contact, immediately flush eyes or skin with plenty of water for at least 15 minutes. Remove contaminated clothing and shoes. Wash clothing before reuse. In all cases, get medical attention. Product Use: Laboratory Reagent. Revision Information: No Changes. Section 16: Other Information – NFPA Diamond Additional Information NIOSH Pocket Guide to Chemical Hazards http://www.cdc.gov/niosh/npg/ International Chemical Safety Cards http://www.cdc.gov/niosh/ipcsneng/neng0000.html ASTDR ToxFaqs http://www.atsdr.cdc.gov/toxfaq.html Quiz Password The password for the online hazard communication quiz is AEEHAZCOM