The Future of Refrigerants

advertisement

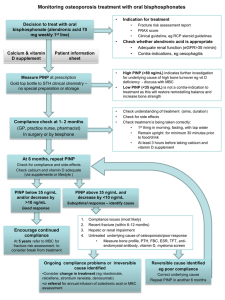

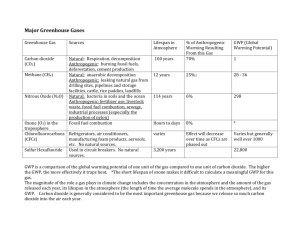

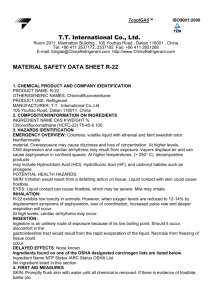

The Current State of R-22 and the Future with New Generation Refrigerants Freon® The DuPont™ Invented, Workhorse Refrigerant of the last 50 years. Refrigerant Management Plan Retrofit System 1 MO99™ Reclaim System 1 R-22 Replace Return to Wholesaler refrigerant reclaim center to get value ($) for R-22 New System R-410A System 2 System 3 System 4 R-22 R-22 R-22 Use recovered R-22 to service other equipment Recovered R-22 Recycle A Low Cost Supply of R-22 System 5 System 6 System 7 R-22 R-22 R-22 R-22 Replacement Refrigerants Mineral Oil Compatible Full change to POE lubricant required R-438A R-407C Air Conditioning Refrigeration R-438A R-422D R-407A Comparing R-22 “No Oil Change” Products for Air Conditioning Applications ISCEON® MO99™ (R-438A) R-422D R-422B R-421A1 Capacity (%) -7 -8 -12 -12 COP (%) -2 -4 -3 -5 Components R-32/125/134a/600/601a 8.5/45/44.2/1.7/0.6 R-125/134a/600a 65.1/31.5/3.4 R-125/134a/600a 55/42/3 Disch P (psi) +5 +12 -5 -7 Disch T (F) -30 -39 -37 -36 Temp Glide (F) +7 +5 +6 +6 Mass Flow (%) +12 +32 +20 +21 Performance relative to R-22; (+) is increase, (-) is decrease Calorimeter Data at AHRI Standard 540 Air Conditioning Conditions; Performance relative to R-22 45 F Avg Evap Temp / 115 F Avg Cond Temp / 65 F Return Gas Temp / 15 F Subcool from Avg Cond Temp 1POE Oil Change typically recommended for ‘HFC Only’ Blends R-125/134a 58/42 R-22 to ISCEON® MO99™ (R-438A) Retrofit Procedure* 1. Review retrofit guidelines 2. Obtain Baseline Data on R-22 3. Recover R-22 4. Change filter driers 5. Change critical elastomeric seals 6. Evacuate system & leak check 7. Charge with MO99™ ; Start-up and monitor 8. Leak Check, Label system, and optimize set-points if needed *ISCEON® MO99™ Retrofit Guidelines and 9. ISCEON® MO99™ Retrofit Video – www.isceon.com Summary of Oil Management Considerations MO99™ excels in most Residential A/C, Commercial A/C, and Refrigeration These considerations are true for ANY “No Oil Change” product System Guidance More complex systems with potential for challenging oil return ~20% POE addition • Long pipe runs and/or poor line velocity design • Liquid receivers but no oil separator present Trane™ 3-D™ Scroll / Danfoss Scroll Replace Oil in Compressor Sump with POE Screw compressors Detailed system evaluation recommended Use of any 400-series retrofit blend is not recommended in systems with flooded evaporators OPTEON® A new generation of low-GWP refrigerants. Why Do We Need New Refrigerants? Worldwide focus on Global Warming (Climate Change) Summary of EPA Proposed Changes to SNAP http://www.epa.gov/ozone/snap/regulations.html Effective Date Refrigerant Proposed Unacceptable for: 2021 Model Year R134a Mobile AC 1/1/16 R404A/R507A Supermarket (Direct/Indirect) Condensing Units Stand Alone Systems Vending Machines New and Retrofit 1/1/16 HFC-227ea, R407B, R421B, R422A, R422C, R422D, R428A, R434A Supermarket (Direct/Indirect) New and Retrofit 1/1/16 R134a and others* Stand Alone Systems Vending Machines New Systems No proposed limitations on service of existing HFC systems Applications *R407A, R407C, R407F etc. Creating the Future of Refrigerants HFOs provide a safe, sustainable, cost effective transition Zero ODP Low GWP No or low flammability Efficiency + Capacity _____________ Performance √ Capital Costs + Operation Costs ______________ Total Cost of Ownership HFO-1234yf (CF3CF=CH2) Very Similar to HFC-134a but with very low GWP 3.5 Pressure, MPa Same operating conditions as 134a (similar P/T curve) Thermally stable under extreme use conditions 3 2.5 2 Vapor Pressure 1.5 134a 1 1234yf 0.5 Capacity and efficiency similar to R-134a 0 -40 0 20 40 60 80 100 Temperature, oC Mildly flammability (A2L) R-134a HFO-1234yf CH2FCF3 CF3CF=CH2 102 114 0 0 1300 1 T Critical Point 102 ºC 95ºC Boiling Point -26ºC -29ºC Formula Molecular Weight ODP GWP100 (AR5) DuPont Confidential -20 How HFOs Work HFC Hydro fluorocarbon HFO Hydro fluoro olefin Weaker double bond in HFOs allows for quicker breakdown in the atmosphere, yet stable in systems Mobile Air Conditioning Commercialized in 2011 New Car Models Market Drivers GWP Regulation in EU, US and Japan Performance Benefits Direct 134a replacement Lower cost per vehicle vs. not-in-kind solutions DuPont Opteon® Refrigerants HFO based candidates Current HFC-134a GWP 1430 HFC-404A 3902 Nonflammable Name GWP XP10 DR-14 XP40 631 389 1397 XP44 2140 HFC-410A HCFC-22 2088 1810 DR-91 988 HCFC-123 77 DR-2 9 Mildly Flammable Name GWP YF 4 DR-7 246 DR-5A DR-3 460 148 AR4 GWP Values Opteon® XP10 R-513A Replacement for 134a Azeotropic refrigerant Excellent capacity and efficiency match for 134a Compatible with existing equipment design/lubricants Reduction in GWP of 56% GWP of 631 falls well below EU 1500/1000 lines XP10 Properties R-134a XP10 Chemical Formula CF3CH2F Azeotrope 100 yr GWP (AR4) 1430 631 Toxicity/Flammability A1 A1 Boiling Point °C (°F) -26 (-15) -29 (-20) Critical Point °C (°F) 101 (214) 98 (208) Temperature Glide °C (F) 0 Negligible (Azeotrope) DuPont Confidential XP10 Calorimeter Testing -- Recip Compressor 2% better energy efficiency 5% higher capacity XP 10 Versus R-134a Calorimeter Test 65F Return Gas Temperature 112% 110% 106% 104% Rel EER Rel Cap 102% 100% 98% 96% 94% Evaporator/Condenser Condition 0F F/ 12 0F 30 F/ 12 20 F/ 12 0F 0F 14 /1 2 0F 5F F/ 10 5F 30 F/ 10 20 F/ 10 5F 5F 14 /1 0 F 0F F/ 80 F 30 F/ 80 F 20 F/ 80 14 /8 0 F 92% 0F XP10 Rel to R-134a 108% XP10 Evaluation in Supermarket - Hybrid System - Retrofitted from R-134a Medium Temp; CO2 in Low Temp - Running for four years DuPont Confidential Annual Energy Use and TEWI Comparison TEWI reduced by 48% vs R-404A system DuPont Confidential Opteon® XP44 R-452A Replacement for 404A/507 Matches discharge temperature of 404A/507 Critical for transport applications Matches mass flow rate of 404A/507 No TXV adjustments necessary Compatible with existing equipment design/lubricants A1 non-flammable Reduction in GWP of 44% GWP of 2140 Opteon® XP40 R-449A Replacement for 404A/507 8-12% more energy efficient than 404A/507 Superior efficiency to CO2 Capacity equivalent to 404A/507 Compatible with existing equipment design/lubricants A1 non-flammable TXV adjustment needed similar to 407 series retrofit Reduction in GWP of 67% GWP of 1397 falls below EU 1500 line XP40 Properties R-404A XP40 100 yr GWP 3922 1397 Flammability None None Boiling Point °C (ºF) -47 (-53) -46 (-51) Critical Point °C (ºF) 72 (162) 82 (180) Vapor Pressure at 25°C in kPa (Psia) 1254 (182) 1274 (185) Liquid Density at 25°C in kg/m3 (lb/ft3) 1044 (65.2) 1096 (68.4) Vapor Density at 25°C in kg/m3 (lb/ft3) 65.3 (4.08) 49.2 (3.07) DuPont Confidential System Testing – Display Case with External Condensing Unit 2.5 m (8.0 ft) open food display case designed for R-404A, fully loaded with food simulator Reciprocating compressor with POE 32 oil Refrigerant charge size ~3.8 kg (8.4 lb), adjusted based on liquid density Tested per ASHRAE Standard 72-2005 Tested at two ambient temps: 28ºC (82ºF) and 35ºC (95ºF) in outdoor room, 24ºC (75ºF) in indoor room Only minor TXV adjustment made (1.6 turns closed) Tested at low and medium temp conditions Open Display Case in Indoor Room Condensing Unit in Outdoor Room DuPont Confidential Condensing Unit/Display Case Low Temp Results Energy Cons Rel to R404A Mass Flow Rate kg/hr (lb/hr) Suct Press kPa (Psia) Disch Press kPa (Psia) Comp Ratio Avg Food Temp ºC (ºF) Comp Disch Temp ºC (ºF) R-404A 100% 32 (71) 112 (16) 1438 (209) 13 -17 (1.4) 78 (172) XP40 97% 26 (57) 104 (15) 1407 (204) 14 -17 (1.4) 83 (181) R-404A 100% 33 (73) 127 (18) 1722 (250) 14 -16 (3.2) 87 (189) XP40 96% 26 (57) 115 (17) 1685 (244) 15 -15 (5.0) 92 (198) Ambient T = 28ºC (82ºF) Ambient T = 35ºC (95ºF) ~3% lower energy consumption Similar pressures and compression ratio Modest increase in discharge T and slightly lower mass flow rate DuPont Confidential Condensing Unit/Display Case Med Temp Results Energy Cons Rel to R404A Mass Flow Rate kg/hr (lb/hr) Suct Press kPa (Psia) Disch Press kPa (Psia) Comp Ratio Avg Food Temp ºC (ºF) Comp Disch Temp ºC (ºF) R-404A 100% 38 (83) 262 (38) 1544 (224) 5.9 2.2 (36) 72 (161) XP40 92% 32 (71) 262 (38) 1496 (217) 5.7 2.2 (36) 75 (167) R-404A 100% 41 (91) 248 (36) 1827 (265) 7.4 2.2 (36) 82 (180) XP40 88% 34 (74) 283 (41) 1792 (260) 6.3 2.8 (37) 84 (183) Ambient T = 28ºC (82ºF) Ambient T = 35ºC (95ºF) 8-12% lower energy consumption Similar pressures and compression ratio Less increase in discharge T and slightly lower mass flow rate DuPont Confidential California Supermarket Conversion from 404A to Opteon® XP40 October 2014 DuPont Confidential Operational Data DuPont Confidential Energy Data Daily Energy Usage and Average Temperature DuPont Confidential Comparison Energy Data DuPont Confidential California Retrofit Summary Energy benefit of 9% from mid-Oct to year end Potential for further benefit at higher ambient temps No changes to equipment, piping, lubricant or seals/gaskets Adjust TXVs for optimized performance Meets cooling demand Stable operation DuPont Confidential 404A/507 Replacement Options Summary GWP < 1500 Energy Efficiency Capacity TXV Adjustment Oil 404A/507 XP40 407A 407F CO2 3902 Base Base Base POE 1397 +8-12% = Yes POE 2107 = = Yes POE 1825 = = Yes POE 1 =/-* NEW EQ NEW EQ NEW EQ * Poor at higher ambient conditions DuPont Confidential Opteon® XP40 R-449A Replacement for R-22 Eliminates a retrofit to 407 series refrigerants Capacity equivalent to 404A/507 Minimal TXV adjustment Reduction in GWP of 22% GWP of 1397 falls below EU 1500 line R-22 Replacement Options Summary GWP < 1500 Eliminates a retrofit ($)? Energy Efficiency Capacity TXV Adjustment Oil R-22 1810 Base Base Base Base MO XP40 1397 Yes = = No POE 407A 2107 No = = No POE 407F 1825 No = = No POE DuPont Confidential Projected Timeline Emerson approval of XP10 and XP40 US Commercialization of XP10, XP44 and XP40 Jul/Aug Mar/Apr 2015