Final Presentation Powerpoint

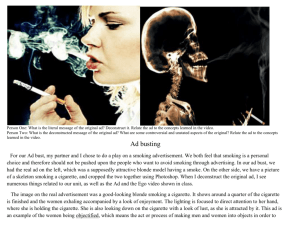

advertisement

RIT College of Engineering Multidisciplinary Senior Design P10054-Monitoring Device for Human Smoking Behavior Final Product Review 19 February 2010 Project Manager Frank Forkl Mechanical Engineer Michael Kraft Mechanical Engineer Brian Gilbane P10054 Systems Engineer Rich Steen Electrical Engineer Derek Ng Objective: Create device which measures natural human smoking behavior Major Requirements: Subjects will need to carry device for up to one month in the field Subject will use device for every cigarette smoked Device must be as unobtrusive as possible Data to capture: Flow Rate through cigarette Total Lung Volume to measure Deep Inhalation Puff •A self-contained battery operated device that measures ambulatory smoking behavior with time and date tags assigned at cigarette insertion/removal. •Onboard memory is used to store all measures for up to four weeks without requiring interaction with study staff. http://www.plowshare.com/products/portable/index.html Major Problems: •Extremely obtrusive which does not allow for natural smoking behavior •Unable to capture entire smoking event (Deep Inhalation Puff) •Performs poorly at bottom of flow rate resolution (less than 17.5 mL/s) •Does not output Flow Curves, just aggregate data •Extremely expensive (~$2000) Remote Handheld Smoking Device Deep Inhalation Puff Sensor Belt Belt Clip Central Unit Ergonomic Handheld (Frank) Flow Meter (Brian) DIP Respiratory Belt (Mike) 5V DC Power 0-5 VDC Signal Belt Output Voltage Belt Clip 5V DC Power 0-5 VDC Signal Conditioning (Derek) 5V DC Power Arduino Microcontroller (Rich) Control Interface (Rich, Frank) Digital I/O +12 VDC Clock Time, Signal Voltages MicroSD Card Shield- Data Storage (Rich) Battery (Derek) Post Collection Data Processing (Rich, Mike, Brian) CSV on MicroSD Card Ergonomic Foam Mock Ups Finished Handheld Designs The deep inhalation puff is the breath of “clean” air after taking an initial draw on a cigarette. This “clean” air includes side stream smoke or commonly known as second hand smoke. By capturing the deep inhalation puff, the device will provide more accurate data than the CReSS device on how a human smokes a cigarette during an entire smoking event. SLP Inc. Inductive Bands •Closed loops of conductive wire woven in an elastic band BioPac Strain Gauge Belt • Linear strain gauge attached to an adjustable elastic band •Flow of the current is limited by a change in magnetic flux •Strain from tension is converted to a voltage signal http://www.sleepsense.com/pages/product http://www.biopac.com/ProductImages/tsd201.jpg The signal-to-noise ratio from the BioPac belt was of a notably higher fidelity before amplification. Criteria for Selection •Cost •Digital and Analog Inputs •Digital Outputs •Flash Memory Arduino Duemilanove •Most economical Conclusions •Real Time Clock (RTC) •Storage •Auto-Reset Serial interface rather than parallel ~0.5 second per write operation Unreliable operation Disposable battery would Requires frequent replacement Process more complicated for the customer. Two main factors capacity of the battery cost. Other factors: size weight amount of voltage supplied Requires external jumper DIP belt signal was too weak to be read properly INA128 Biomedical Amplifier is a higher fideltiy 2 1 Inaccuracies of either correlation Experimental noise Leaks in the pressure sensor system Air taken in by the smoker but not going through the cigarette Feature Cigarette Detection (Infrared or other method) Wireless Communication Between Device Components Rationale Time, Lack of EE Expertise, Deemed Bell/Whistle Not necessary, possibly not actually desirable (losing pieces), lack of EE/CE expertise Wireless Communication for Data Transfer Time, Lack of EE/CE Expertise, Deemed Bell/Whistle Internal Permanent Connection Between Board and Battery Time, Lack of EE Expertise E-cigarette Adapter Time, Deemed Bell/Whistle Flow Path Optimization Time, Lack of CFD expertise, will begin this work Onboard Zeroing Sensors Very challenging problem, solution is being attempted but is not guaranteed Time, Deemed Bell/Whistle, not wholly necessary Custom DIP Belt Design Time, Lack of Expertise/Understanding in a timely manner, Cost Embedded Software Upgrades: Power Management, Data Processing, Automated Calibration Time, Lack of CE Expertise, team will make software functional and as advanced as possible Cigarette Vent Hole Issue Battery Life Improvements Case Design Upgrades for Moldability Further Ergonomic Testing and Improvements Lack of EE expertise. Incremental improvement, our design will be adequate but could be improved Time. Necessary for ramp up, will get done if possible Time: incremental improvement achieved through additional focus group Adding Retractable Wire Mechanism to Device Difficulty locating vendor of appropriate pre-fabbed mechanism. Will likely need custom design or custom part from vendor. Improved Durability Limited time to design case internal structure. Will meet minimum level but cannot guarantee beyond that All pictures used under educational fair use