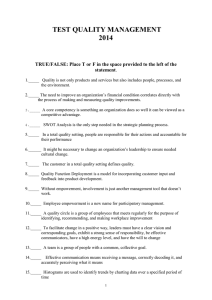

TRUE/FALSE

advertisement

Dear students, Here below you will find the correct answers to all test questions. As you know, the lectures have been based mostly on the following two books: 1. Quality Management for organizational excellence (by David L.Goesch and Stanley Davis) 2. Juran´s Quality Handbook (6th edition) Many questions in the test have been taken from the test material provided by the authors of the first book. The authors have also provided correct answers, which I have used in the evaluation of the test results. Here below is a summary of the results: True/false: There are 31 (55%) questions to which all of you had a correct answer! On the other hand, 7 questions were wrongly answered by more than 8 students. For those I have added explanations in the text of the test. (Question number 42 was unfortunately not formulated well enough, so I have counted both true and false answers as correct.) Multiple choice: There are 15 (65%) questions to which all of you had a correct answer! There are no questions which were wrongly answered by more than 8 students. Should you have any questions, please do not hesitate to contact me. Jiri Pesak Prague, June 9, 2014 1 TEST QUALITY MANAGEMENT 2014 TRUE/FALSE: Place T or F in the space provided to the left of the statement. 1.__T___ Quality is not only products and services but also includes people, processes, and the environment. 2.__T___ The need to improve an organization’s financial condition correlates directly with the process of making and measuring quality improvements. 3.___T__ A core competency is something an organization does so well it can be viewed as a competitive advantage. 4.__F___ SWOT Analysis is the only step needed in the strategic planning process. 5.__T___ In a total quality setting, people are responsible for their actions and accountable for their performance 6.___T___ It might be necessary to change an organization’s leadership to ensure needed cultural change. 7.___T_ The customer in a total quality setting defines quality. 8.___T__ Quality Function Deployment is a model for incorporating customer input and feedback into product development. 9.___T__ Without empowerment, involvement is just another management tool that doesn’t work. 10.__F___ Employee empowerment is a new name for participatory management. Participatory management is about managers and supervisors asking for their employees help. Empowerment is about getting employees to help themselves, each other and the company 11.__T___ A quality circle is a group of employees that meets regularly for the purpose of identifying, recommending, and making workplace improvement 12.__T__ To facilitate change in a positive way, leaders must have a clear vision and corresponding goals, exhibit a strong sense of responsibility, be effective communicators, have a high energy level, and have the will to change 2 13.__T___ A team is a group of people with a common, collective goal. 14.___F__ Effective communication means receiving a message, correctly decoding it, and accurately perceiving what it means Communication is the transfer of a message that is both received and understood. Effective communication means that the message is received, understood and acted on in a desired manner 15.___F__ Histograms are used to identify trends by charting data over a specified period of time. It is the run chart that records the output results of a process over time. For this reason, the run chart is sometimes called a trend chart . 16.___T__ The fishbone diagram is the only tool of the seven tools that is not based on statistics. 17.___F__ Control charts are used to investigate the cause of a problem by grouping data into categories. 18.___T__ Specification limits are decided by people 19.___T__ Control limits are determined by the process data 20.___T__ Design of experiments is a very sophisticated method for experimenting with processes with the objective of optimizing them. 21.___T__ Decision making is a critical task in a total quality setting because an organization cannot proceed until decisions are made. 22.___T__ Special variation is the result of factors that are not part of the process and that occur only in special circumstances. Special cause variation always arrives as a surprise. It is a variability that comes from some extraordinary event. This in contrary to common cause variation which is the “noise” within the system and is inherent in the design of the process. 23.___T__ Quality Function Deployment is a practice for designing your processes in response to customer needs. 24.___T__ Variation in any amount is considered a negative on quality. Highest quality is achieved when the product meets the target value. Any variation to the target value has a negative influence on quality 25.___T__ A project improvement team should consist of representatives from units that are most closely related to the problem in question. 26.___F__ After the source of variation has been identified, it is important for the team to reduce the variation by one-half. 3 27.___F__ PDCA method is used in very complex problems only 28.___T__ Flow production means production that runs smoothly and steadily without interruption. 29.___F__ Kaizen means halting an entire process when a defect is discovered so that it won’t cause additional problems down the line. 30.___F__ Just-in-time is a push system. 31.___T__ In the Kanban System the production flow should be such that subsequent processes withdraw from preceding processes in regular intervals and quantities. 32.___F_ JIT and automation are not compatible. 33.___F__ Value stream map can be used only in manufacturing environment 34.__F__ ISO 9000 and total quality are interchangeable. 35.___T__ ISO 9000 is compatible with, and can be a subset of total quality. 36.___T__ EFQM excellence model is not a standard 37.___F__ EFQM excellence model cannot be used for self-assessment 38.___T___Costs of Poor Quality include Internal and External Failure Costs 39.___F___Costs of Poor Quality are usually less than 2% of the Sales 40.___F___In the Best-in-Class approach the Price of a product is determined by the organization In the traditional approach the Price is determined by the organization (Cost+Profit=Price) In the Best-in-Class approach the Price is determined by the Customer (how much is he willing to pay for it), (Price-Profit=Cost) 41.___F___Attractive/Exciting Quality Attributes are demanded by the Customers 42.___F___VA/VE process aims only at increasing value of the product VA/VE process aims at either increasing the value of the product at the same cost or reducing the cost while keeping the same value 43.___F___The main task of the Leaders is to cope with complexity Main task of the Leaders is coping with change, main task of the Managers is coping with complexity 44.___F___ Correlation coefficient r = -2 reflects a perfect negative correlation 4 45___F___ The weakness of the run chart is that it does not show the trend 46.___T____p-chart is used to monitor the number of nonconforming units in a sample 47.____F___Common cause variation comes from extraordinary events 48.____F___The quality loss function attempts to measure quality as loss due to deviation from tolerance limits 49.____T__IPO diagrams are “high-level” process maps 50.___F___Area of extreme risks is determined by high potential damage and low damage occurrence 51.___F___Product liability applies to manufacturers of products only 52.___T___The purpose of FMEA is to take actions to prevent, eliminate or reduce failures, starting with the highest priority ones. 53.___T___FMEA can be used for analysis of software functions 54.___F___8D problem solving methodology means that the problem should be solved in 8 Days. 55.___F___The purpose of the 5 times Why methodology is to correct the symptoms of a problem 56.___T___Use of Quality Tools and Techniques is essential in implementing Total Quality concept. MULTIPLE CHOICE: Circle the letter before the correct answer in each of the following questions. 1. Which of the following functions is part of the Juran Trilogy? A. Pareto Principle B. Quality planning C. Unity of purpose D. Six Sigma Program 2. The most important key in maximizing competitiveness is: A. Education B. Human resources C. Teamwork D. Government 3. Which of the following statements best describe the acronym SWOT? A. Specific, Witness, Opportunities, and Time. B. Single, Weaknesses, Occasion, and Tactics. C. Strengths, Weaknesses, Opportunities, and Threats. 5 D. Strategic, Weaknesses, Objectives, and Tactics. 4. Partnering can lead to continual improvements in such key areas as relationships between customers and suppliers, customer satisfaction, and A. Increased competitiveness B. Increased resources C. Processes and products D. Quality control 5. In a total quality setting, quality is defined by: A. The employee B. The customer C. The management D. The organization 6. Employee empowerment is: A. Employee involvement in decision making. B. Power of the employee to make suggestions that will be reviewed by management C. Employee input that is heard, seriously considered, and followed up on whether it is accepted or not. D. Power of the employee to make a decision without management involvement. 7. Which of the following is the most appropriate leadership style in a total quality setting? A. Autocratic B. Democratic C. Participative D. Goal-orientated 8. Which of the following strategies are applied in order to be a good team member? A. Establish ground rules B. Be well prepared and participate C. Identify success criteria D. None of the above 9. What percentage of what is read is remembered and retained? A. 50% B. 30% C. 90% D. 10% 10. Which of the following statements outline the relationship factor? A. ISO 9000 and total quality are not in competition B. ISO 9000 and total quality are not interchangeable C. ISO 9000 is compatible with total quality 6 D. All of the above 11. The characteristics of total quality are: A. Scientific approach to problem solving and decision making B. Concerned only with quality management procedures C. Unity of purpose—all employees, all levels D. Both A & C 12. Which of the following statements are true concerning ISO 9000? A. The aim of ISO 9000 is to transform organizations into competitive players in the global marketplace. B. The aim of ISO 9000 was to create a universally recognized family of standards. 13. The purpose of the Pareto Chart is: A. To identify an isolate the causes of a problem B. To show where to apply resources by revealing the significant few from the trivial many C. To collect variables data D. To determine the correlation between two characteristics 14. Which of the following tells whether the variation is the result of special causes or common causes? A. Histogram B. Check Sheet C. Run Chart D. Control Chart 15. The reason for using a team in solving problems is: A. Because it is important to promote teamwork B. Because no individual knows as much as a team C. Because it is easier to get employees to talk D. All of the above 16. Pareto Charts: A. Focus a group, thereby reducing irrelevant discussion B. Separate causes from symptoms and force the issue of data collection C. Help sort out what problems or causes of problems to pursue first D. Identify trends by charting data over a specified period of time 17. What portion of the QFD house explanation is where customer requirements are converted into manufacturing terms? A. The wall B. The roof C. The middle D. The bottom 18. Which of the following is the most widely used of the QFD tools? A. Tree diagram 7 B. Interrelationship digraph C. Affinity diagram D. Matrix diagram 19. Which of the following is considered a benefit of JIT manufacturing? A. Reduced time-to-market B. Improvement of employee work life C. Flexibility D. All of the above 20. What number of defects can we expect from a Six Sigma process? A. 3 in 1000 B. 3 in 10.000 C. 3 in 100.000 D. 3 in 1.000.000 21. EFQM excellence model has following number of criteria A. 8 B. 9 C. 10 D. 11 22. QFD stands for: A. Quality For Design B. Quality Function Deployment C. Quality Flow Diagram D. Quality Feasibility Detection 23. Failures in the FMEA are prioritized according to: A. Occurrence, Severity, Cost B. Occurrence, Severity, Detection C. Severity, Detection, Cost D. Cost, Detection, Customer Impact 8