Lumped Capacity Analysis: Solved Heat Transfer Problems

advertisement

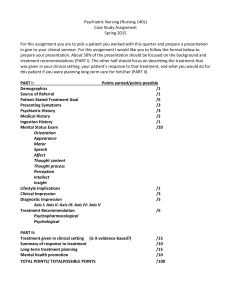

What is Lumped capacity analysis and obtain the expression for temperature distribution of the

same?

All solids have a finite thermal conductivity and there will be always a temperature gradient

inside the solid whenever heat is added or removed. However for solids of large thermal conductivity

with surface areas that are large in proportion to their volume like plates and thin metallic wires, the

internal resistance {L/ kA} can be assumed to be small or negligible in comparison with the

convective resistance {1/hA} at the surface. Typical examples of this type of heat flow are:

1. Heat treatment of metals

2. Time response of thermocouples and thermometers

The process in which the internal resistance is assumed negligible in comparison with its surface

resistance is called the Newtonian heating or cooling process. The temperature, in this process is

considered to be uniform at a given time. Such an analysis is called Lumped parameter analysis

because the whole solid, whose energy at any time is a function of its temperature and total heat

capacity is treated as one lump.

Let us consider a body whose initial temperature is ti throughout and which is placed suddenly in

ambient air or any liquid at a constant temperature to as shown in figure.

Q = - VCp

dT

hAT Ta

dt

dT

hA

(T Ta) VCp dt

ln T Ta

T – Temp pf body at any time

Ta – Ambient Temp

hA

t C1

VCp

The boundary conditions are t=0 T = Ti

C1 ln Ti Ta

Sub C1 in the above equation

ln T Ta

hA

t ln Ti Ta

VCp

T Ta

hA

exp

t

Ti Ta

VCp

SOLVED PROBLEMS IN UNSTEADY CONDUCTION HEAT TRANSFER

24. An aluminium cube 6 cm on a side is originally at a temperature of 500C. It is suddenly immersed in

a liquid at 10C for which h is 120 W/m2K. Estimate the time required for the cube to reach a

temperature of 250C. For aluminium = 2700 kg/m3, C = 900 J/kg K, K = 204 W/mK.

1

Given

Thickness of cube L = 6 cm = 0.06 m

Initial temperature T0 = 500C + 273 = 773 K

Final temperature T = 10C + 273 = 283 K

Intermediate temperature T = 250C + 273 = 523 K

Heat transfer co-efficient h = 120 w/m2K

Density = 2700 kg/m3

Specific heat C = 900 J/Kg k

Thermal conductivity K = 204 W/mK

Solution

For Cube,

Characteristic length

0.06

6

Lc

L

6

Lc 0.01 m

We know

hLc

K

Biot number

120 0.01

204

5.88

10 3 0.1

Bi =

Bi

Biot number value is less than 0.1. So this is lumped heat analysis type problem

For lumped parameter system,

hA

t

T T

C V

e

....(1)

T0 T

[From HMT data book Page No.48]

We know,

V

Lc

A

Characteristics length

h

t

T-T

C L

(1)

e c

T0 T

120

t

523 - 283

e 9000.012700

773 - 283

-120

In (0.489) =

t

900 0.01 2700

t = 144.86 s

Time required for the cube to reach 250C is 144.86 s.

2

25. A copper plate 2 mm thick is heated up to 400C and quenched into water at 30C. Find the time

required for the plate to reach the temperature of 50C. Heat transfer co-efficient is 100 W/m2K. Density

of copper is 8800 kg/m3. Specific heat of copper = 0.36 kJ/kg K.

Plate dimensions = 30 30 cm.

Given

Thickness of plate L = 2 mm = 0.002 m

Initial temperature T0 = 400C + 273 = 673 K

Final temperature T = 30C + 273 = 303 K

Intermediate temperature T = 50C + 273 = 323 K

Heat transfer co-efficient h = 100 W/m2K

Density = 8800 kg/m3

Specific heat C= 360 J/kg k

Plate dimensions = 30 30 cm

To find

Time required for the plate to reach 50C.

[From HMT data book Page No.2]

Solution:

Thermal conductivity of the copper K = 386 W/mK

For slab,

L

Lc

2

Characteristic length

0.002

2

=

Lc 0.001 m

We know,

hLc

K

Biot number

100 0.001

386

4

Bi = 2.59 10 0.1

Bi

Biot number value is less than 0.1. So this is lumped heat analysis type problem.

For lumped parameter system,

hA

t

T T

C V

e

T0 T

……….(1)

[From HMT data book Page No.48]

We know,

V

Characteristics length Lc = A

3

h

t

T-T

C L

(1)

e c

T0 T

100

t

323 - 303

e 3600.0018800

673 - 303

t = 92.43 s

Time required for the plate to reach 50C is 92.43 s.

26. A 12 cm diameter long bar initially at a uniform temperature of 40 C is placed in a medium at 650C

with a convective co-efficient of 22 W/m2K. Determine the time required for the center to reach 255C.

For the material of the bar, K = 20 W/mK, Density = 580 kg/m3, specific heat = 1050 J/kg K.

Given:

Diameter of bar, D = 12 cm = 0.12 m

Radius of bar, R = 6 cm = 0.06 m

Initial temperature T0 = 40C + 273 = 313 K

Final temperature T = 650C + 273 = 923 K

Intermediate temperature T = 255C + 273 = 528 K

Heat transfer co-efficient h = 22 W/m2K

Thermal conductivity K = 20 W/mK

Density = 580 kg/m3

Specific heat C = 1050 J/kg k

Solution

For cylinder,

Lc

Characteristic Length

0.06

=

2

R

2

Lc 0.03 m

We know,

hLc

K

Biot number

22 0.03

20

Bi

Bi = 0.033 < 0.1

Biot number value is less than 0.1. So this is lumped heat analysis type problem.

For lumped parameter system,

hA

t

T T

C V

e

T0 T

……….(1)

[From HMT data book Page No.48]

We know,

4

V

Characteristics length Lc = A

h

t

T-T

C Lc

(1)

e

T0 T

22t

528 - 923

e 10500.03580

313 - 923

t = 360.8 s

Time required for the cube to reach 255C is 360.8 s.

27. A steel ball (specific heat = 0.46 kJ/kgK. and thermal conductivity = 35 W/mK) having 5 cm

diameter and initially at a uniform temperature of 450C is suddenly placed in a control environment in

which the temperature is maintained at 100C. Calculate the time required for the balls to attained a

temperature of 150C. Take h = 10W/m2K.

Given

Specific heat C = 0.46 kJ/kg K = 460 J/kg K

Thermal conductivity K = 35 W/mK

Diameter of the sphere D = 5 cm = 0.05 m

Radius of the sphere R = 0.025 m

Initial temperature T0 = 450C + 273 = 723 K

Final temperature T = 100C + 273 = 373 K

Intermediate temperature T = 150C + 273 = 423 K

Heat transfer co-efficient h = 10 W/m2K

To find

Time required for the ball to reach 150C

[From HMT data book Page No.1]

Solution

Density of steel is 7833 kg/m3

7833 kg / m3

For sphere,

Lc

Characteristic Length

0.025

=

3

R

3

Lc 8.33 103 m

We know,

Bi

hLc

K

Biot number

10 8.3 10 3

35

5

Bi = 2.38 10-3 < 0.1

Biot number value is less than 0.1. So this is lumped heat analysis type problem.

For lumped parameter system,

hA

t

T T

C V

e

T0 T

……….(1)

[From HMT data book Page No.48]

We know,

V

Characteristics length Lc = A

h

t

T-T

C L

(1)

e c

T0 T

10

t

423 - 373

3

e 4608.3310 7833

723 - 373

423 - 373

10

In

t

723 - 373 460 8.33 10 3 7833

t = 5840.54 s

Time required for the ball to reach 150C is 5840.54 s.

28. An aluminium sphere mass 5.5 kg and initially at a temperature of 290o is suddenly immersed in a

fluid at 15C with heat transfer co-efficient 58 W/m3K. Estimate the time required to cool the aluminium

to 95C. For aluminium take = 2700 kg/m3, C = 900 J/kg K, K = 205 W/mK.

Given

Mass, m = 5.5 kg

Initial temperature T0 = 290C + 273 = 563 K

Final temperature T = 15C + 273 = 288 K

Intermediate temperature T = 95C + 273 =368 K

Heat transfer co-efficient h = 58 W/m2K

Thermal conductivity K = 205 W/mK

Density = 2700 kg/m3

Specific heat C = 900 J/kg K.

Solution

We know,

mass

m

Density = volume V

m

V=

=

5.5

2700

V 2.037 10 3 m3

6

We know,

V

4

R3

3

Volume of sphere

3V 3 2.03 103

R3

4

4

R 0.0786 m

For sphere,

R

Lc

3

Characteristic Length

0.0786

=

3

Lc 0.0262 m

We know,

hLc

K

Biot number

58 0.0262

205

Bi

Bi = 7.41 10-3 < 0.1

Biot number value is less than 0.1. So this is lumped heat analysis type problem.

For lumped parameter system,

hA

t

T T

C V

e

T0 T

……….(1)

[From HMT data book Page No.48]

We know,

V

Characteristics length Lc = A

h

t

T-T

C L

(1)

e c

T0 T

58

t

368 - 288

e 9000.02622700

563 - 288

58

368 - 288

In

t

563 - 288 900 0.0262 2700

t = 1355.36 s

Time required to cool the aluminium to 95C is 1355.6 s.

7

29. Alloy steel ball of 2 mm diameter heated to 800C is quenched in a bath at 100C. The material

properties of the ball are K = 205 kJ/m hr K, = 7860 kg/m3, C = 0.45 kJ/kg K, h = 150 KJ/ hr m2 K.

Determine (i) Temperature of ball after 10 second and (ii) Time for ball to cool to 400C.

Given

Diameter of the ball D = 12 mm = 0.012 m

Radius of the ball R = 0.006m

Initial temperature T0 = 800C + 273 = 1073 K

Final temperature T = 100C + 273 = 373 K

Thermal conductivity K = 205 kJ/m hr K

205 1000J

3600 s mK

56.94 W / mK

[ J/s = W]

Density = 7860 kg/m3

Specific heat C = 0.45 kJ/kg K

= 450 J/kg K

Heat transfer co-efficient h = 150 kJ/hr m2 K

150 1000J

3600 s m2K

41.66 W / m2K

Solution

Case (i) Temperature of ball after 10 sec.

For sphere,

Characteristic Length

R

3

0.006

=

3

Lc

Lc 0.002 m

We know,

hLc

K

Biot number

41.667 0.002

56.94

Bi

Bi = 1.46 10-3 < 0.1

Biot number value is less than 0.1. So this is lumped heat analysis type problem.

For lumped parameter system,

hA

t

T T

C V

e

T0 T

……….(1)

[From HMT data book Page No.48]

We know,

8

V

Characteristics length Lc = A

h

t

T-T

C L

(1)

e c

T0 T

..........(2)

41.667

10

T - 373

e 4500.0027860

1073 - 373

T = 1032.95 K

Case (ii) Time for ball to cool to 400C

T = 400C + 273 = 673 K

h

t

T-T

C L

(2)

e c

T0 T

41.667

.......(2)

t

673 - 373

e 4500.0027860

1073 - 373

41.667

673 - 373

In

t

1073 - 373 450 0.002 7860

t = 143.849 s

30. A large wall 2 cm thick has uniform temperature 30C initially and the wall temperature is suddenly

raised and maintained at 400C. Find

The temperature at a depth of 0.8 cm from the surface of the wall after 10 s.

Instantaneous heat flow rate through that surface per m2 per hour.

Take = 0.008 m2/hr, K = 6 W/mC.

Given

Thickness L = 2 cm = 0.02 m

Initial temperature Ti = 30C + 273 = 303 K

Surface temperature T0 = 400C + 273 = 673 K

Thermal diffusivity = 0.008 m2/h

= 2.22 10-6 m2/s

Thermal conductivity K = 6 W/mC.

Case (i)

Depth 0.8 cm = 0.8 10-2 m

= 0.008 m

Time t = 10 s

Case (ii)

Time t = 1 h = 3600 s

Solution

9

In this problem heat transfer co-efficient h is not given. So take it as . i.e. h .

We know that,

hLc

Biot number Bi = K

h=

Bi

Bi value is . So this is semi infinite solid type problem.

Case (i)

For semi infinite solid.

Tx T0

x

erf

Ti T0

2 at

[From HMT data book Page No. 50]

Tx T0

erf (X) .......(1)

Ti T0

Where,

x

X

2 at

Put x = 0.008 m, t = 10 s, = 2.22 10-6 m2/s.

X=

0.008

2 2.22 10-6 10

X = 0.848

X = 0.848, corresponding erf (X) is 0.7706

erf (X) = 0.7706

[Refer HMT data book Page No.52]

(1)

Tx -T0

0.7706

Ti T0

Tx - 673

0.7706

303 - 673

T - 673

x

0.7706

- 370

Tx = 387.85 K

Case (ii)

10

Instantaneous heat flow

qx

K T0 Ti

a t

e

x2

4 t

[From HMT data book Page No.50]

t = 3600 s (Given)

qx

6 (673 303)

2.22 10-6 3600

e

(0.008)2

6

42.2210 3600

qx 13982.37 W / m2

Intermediate temperature Tx = 387.85 K

Heat flux qx = 13982.37 W/m2.

31. A large cast iron at 750C is taken out from a furnace and its one of its surface is suddenly lowered

and maintained at 45C. Calculate the following:

The time required to reach the temperature 350C at a depth of 45 mm from the surface.

Instantaneous heat flow rate at a depth of 45 mm and on surface after 30 minutes.

Total heat energy after 2 hr for ingot,

Take = 0.06 m2/hr, K = 48.5 W/mK.

Given

Initial temperature Ti = 750C + 273 = 1023 K

Surface temperature T0 = 45C + 273 = 318 K

Intermediate temperature Tx = 350C + 273 = 623 K

Depth x = 45 mm = 0.045 m

Thermal diffusivity = 0.06 m2/hr = 1.66 10-5 m2/s

Thermal conductivity K = 48.5 W/mK.

Solution

In this problem heat transfer co-efficient h is not given. So take it as , i.e. h .

We know that,

hLc

Biot number Bi = K

h=

Bi

Bi value is . So this is semi infinite solid type problem.

1. For semi infinite solid.

11

Tx T0

x

erf

Ti T0

2 at

[From HMT data book Page No. 50]

Tx T0

erf (X) where,

Ti T0

x

X

2 at

623 318

erf (X)

1023 318

0.432 = erf (X)

erf (X) = 0.432

erf (X) = 0.432, corresponding X is 0.41

X 0.41

We know

X

x

2 at

0.045

0.41 =

2 1.66 10-5 t

(0.045)2

2

(0.41)

(2)2 1.66 105 t

t = 181.42 s

Time required to reach 350C is 181.42 s.

2. Instantaneous heat flow

qx

K T0 Ti

a t

e

x2

4 t

[From HMT data book Page No.50]

t = 30 minutes (Given)

t = 1800 s

qx

48.5 (318 1023)

1.66 10 1800

-5

e

(0.045)2

5

41.6610 1800

qx 109725.4 W / m2

[Negative sign shows that heat lost from the ingot].

12

3. Total heat energy

q 2K[T0 Ti ]

t

7200

1.66 10 5

[Time is given, 2 hr = 7200 s]

2 48.5(318 1023)

q 803.5 106 J/ m2

[Negative sign shows that heat lost from the ingot]

32. A large steel plate 5 cm thick is initially at a uniform temperature of 400C. It is suddenly exposed on

both sides to a surrounding at 60C with convective heat transfer co-efficient of 285 W/m2K. Calculate

the centre line temperature and the temperature inside the plate 1.25 cm from themed plane after 3

minutes.

Take K for steel = 42.5 W/mK, for steel = 0.043 m2/hr.

Given

Thickness L = 5 cm = 0.05 m

Initial temperature Ti = 400C + 273 = 673 K

Final temperature T = 60C + 273 = 333 K

Distance x = 1.25 mm = 0.0125 m

Time t = 3 minutes = 180 s

Heat transfer co-efficient h = 285 W/m2K

Thermal diffusivity = 0.043 m2/hr

= 1.19 10-5 m2/s.

Thermal conductivity K = 42.5 W/mK.

Solution

For Plate :

Characteristic Length

Lc

=

L

2

0.05

2

Lc 0.025 m

We know,

hLc

K

Biot number

285 0.025

42.5

Bi 0.1675

Bi

0.1 < Bi < 100, So this is infinite solid type problem.

Infinite Solids

13

Case (i)

[To calculate centre line temperature (or) Mid plane temperature for infinite plate, refer HMT data

book Page No.59 Heisler chart].

t

X axis Fourier number = 2

Lc

=

1.19 10-5 180

(0.025)2

X axis Fourier number = 3.42

Curve

hLc

K

285 0.025

0.167

42.5

Curve

hLc

0.167

K

X axis value is 3.42, curve value is 0.167, corresponding Y axis value is 0.64

Y axis =

T0 T

0.64

Ti T

T0 T

0.64

Ti T

T0 T

0.64

T

T

i

T0 333

0.64

673 333

T0 550.6 K

Center line temperature T0 550.6 K

Case (ii)

Temperature (Tx) at a distance of 0.0125 m from mid plane

[Refer HMT data book Page No.60, Heisler chart]

hL

X axis Biot number Bi c 0.167

K

x 0.0125

Curve

0.5

Lc

0.025

X axis value is 0.167, curve value is 0.5, corresponding Y axis value is 0.97.

14

Tx T

0.97

T0 T

Y axis =

Tx T

0.97

T0 T

Tx T

0.97

T0 T

Tx 333

0.97

550.6 333

Tx 544 K

Temperature inside the plate 1.25 cm from the mid plane is 544 K.

33. A 10 cm diameter apple approximately spherical in shape is taken from a 20C environment and

placed in a refrigerator where temperature is 5C and average heat transfer coefficient is 6 W/m2K.

Calculate the temperature at the centre of the apple after a period of 1 hour. The physical properties of

apple are density = 998 kg/m3. Specific heat = 4180 J/kg K, Thermal conductivity = 0.6 W/mK.

Given:

Diameter of sphere D = 10 cm = 0.10 m

Radius of sphere R = 5 cm = 0.05 m

Initial temperature Ti = 20C + 273 = 293 K

Final temperature T = 5C + 273 = 278 K

Time t = 1 hour = 3600 s

Density = 998 kg/m3

Heat transfer co-efficient h = 6 W/m2K

Specific heat C = 4180 J/kg K

Thermal conductivity K = 0.6 W/mK

K

0.6

C 998 4180

Thermal diffusivity =

1.43 107 m2 / s.

Solution

For Sphere,

Lc

Characteristic Length

0.05

=

3

R

3

Lc 0.016 m

We know,

Biot number

Bi

hLc

K

15

6 0.016

0.6

Bi 0.16

0.1 < Bi < 100, So this is infinite solid type problem.

Infinite Solids

[To calculate centre line temperature for sphere, refer HMT data book Page No.63].

X axis =

t

R2

1.43 10-7 3600

=

(0.05)2

X axis = 0.20

Curve

hR

K

6 0.05

0.5

0.6

Curve 0.5

X axis value is 0.20, curve value is 0.5, corresponding Y axis value is 0.86.

T0 T

0.86

Ti T

Y axis =

T0 T

0.86

Ti T

T0 278

0.86

293 278

T0 290.9 K

Center line temperature T0 = 290.9 K.

34. A long steel cylinder 12 cm diameter and initially at 20C is placed into furnace at 820C with h =

140 W/m2K. Calculate the time required for the axis temperature to reach 800C. Also calculate the

corresponding temperature at a radius of 5.4 cm at that time. Physical properties of steel are K = 21

W/mK, = 6.11 10-6 m2/s.

Given:

Diameter of cylinder D = 12 cm = 0.12 m

Radius of sphere R = 6 cm = 0.06 m

Initial temperature Ti = 20C + 273 = 293 K

Final temperature T = 820C + 273 = 1093 K

Heat transfer co-efficient h = 140 W/m2K

16

(or)

T0 800C 273 1073 K

Centre line temperature

Intermediate radius r = 5.4 cm = 0.054 m

Thermal diffusivity = 6.11 10-6 m2/s.

Thermal conductivity K = 21W/mK

Axis temperature

To find

Time (t) required for the axis temperature to reach 800C.

Corresponding temperature (Tt) at a radius of 5.4 cm.

Solution

For Cylinder,

Characteristic Length

Lc 0.03 m

Lc

R 0.06

2

2

We know,

hLc

Biot number Bi = K

140 0.03

21

Bi 0.2

0.1 < Bi <100, So this is infinite solid type problem.

Infinite Solids

Case (i)

Axis temperature

(or)

T0 800C

Centre line temperature

To = 800C + 273 = 1073 K

Time (t) ?

[Refer HMT data book Page No.61. Heisler chart]

hR

K

140 0.06

=

0.4

21

Curve

Y axis =

=

T0 T

Ti T

1073 - 1093

293 - 1093

Y axis = 0.025

17

Curve value is 0.4, Y axis 0.025, corresponding X axis value is 5.

T0 T

0.025

Ti T

t

5

R2

5 (0.06)2

t=

(6.11 10 -6 )

X axis =

t 2945.9 s

Case (ii)

Intermediate radius r – 5.4 cm = 0.054 m

[Refer HMT data book Page No.62]

r 0.054

0.9

R 0.06

hR

X axis =

K

140 0.06

=

0.4

21

Curve

Curve value is 0.9, X axis value is 0.4, corresponding Y axis value is 0.84.

Tr T

0.84

T0 T

Y axis =

Tr T

0.84

T0 T

Tr 1093

0.84

1073 1093

Tr 1076.2 K

Time required for the axis temperature to reach 800C is 2945.9 s.

Temperature (Tr) at a radius of 5.4 cm is 1076.2 K

2 Marks Question and Answer

24. What is meant by steady state heat conduction?

If the temperature of a body does not vary with time, it is said to be in a steady state and that type

of conduction is known as steady state heat conduction.

25. What is meant by Transient heat conduction or unsteady state conduction?

18

If the temperature of a body varies with time, it is said to be in a transient state and that type of

conduction is known as transient heat conduction or unsteady state conduction.

26. What is Periodic heat flow?

In periodic heat flow, the temperature varies on a regular basis.

Example:

1. Cylinder of an IC engine.

2. Surface of earth during a period of 24 hours.

27. What is non periodic heat flow?

In non periodic heat flow, the temperature at any point within the system varies non linearly with

time.

Examples :

1. Heating of an ingot in a furnace.

2. Cooling of bars.

28. What is meant by Newtonian heating or cooling process?

The process in which the internal resistance is assumed as negligible in comparison with its

surface resistance is known as Newtonian heating or cooling process.

29. What is meant by Lumped heat analysis?

In a Newtonian heating or cooling process the temperature throughout the solid is considered to

be uniform at a given time. Such an analysis is called Lumped heat capacity analysis.

30. What is meant by Semi-infinite solids?

In a semi infinite solid, at any instant of time, there is always a point where the effect of heating

or cooling at one of its boundaries is not felt at all. At this point the temperature remains unchanged. In

semi infinite solids, the biot number value is .

31. What is meant by infinite solid?

A solid which extends itself infinitely in all directions of space is known as infinite solid.

In semi infinite solids, the biot number value is in between 0.1 and 100.

0.1 < Bi < 100.

32. Define Biot number.

It is defined as the ratio of internal conductive resistance to the surface convective resistance.

Bi =

Bi =

Internal conductive resistance

Surface convective resistance

hLL

.

K

19

33. What is the significance of Biot number?

Biot number is used to find Lumped heat analysis, semi infinite solids and infinite solids

If Bi < 0.1 L Lumped heat analysis

Bi = Semi infinite solids

0.1 < Bi < 100 Infinite solids.

34. Explain the significance of Fourier number.

It is defined as the ratio of characteristic body dimension to temperature wave penetration depth in

time.

Fourier Number =

Characteristic body dimension

Temperature wave penetration

depth in time

It signifies the degree of penetration of heating or cooling effect of a solid.

35. What are the factors affecting the thermal conductivity?

1.

2.

3.

4.

5.

Moisture

Density of material

Pressure

Temperature

Structure of material

36. Explain the significance of thermal diffusivity.

The physical significance of thermal diffusivity is that it tells us how fast heat is propagated or it

diffuses through a material during changes of temperature with time.

37. What are Heisler charts?

In Heisler chart, the solutions for temperature distributions and heat flows in plane walls, long

cylinders and spheres with finite internal and surface resistance are presented. Heisler charts are nothing

but a analytical solutions in the form of graphs.

20