Rotating Drum Downward Hide Puller

advertisement

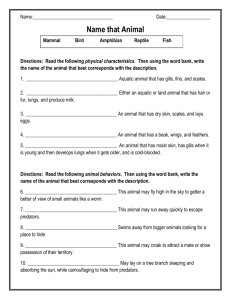

Meat i ng change - Processing Rotating Drum Downward Hide Puller The puller can apply a force of two tonnes when pulling the hide from a body allowing it to handle all sizes of cattle, within reason, that will be processed. This force can be altered to suit the individual needs of plants by changing the specifications of the hydraulic power pack. Meat & Livestock Australia Technology Transfer Kits This Technology Transfer Kit is one in a series of Do-It-Yourself (DIY) resources prepared for the Australian meat industry to encourage the development of project engineering skills at meat processing sites while implementing simple but useful items of technology. This kit is designed to provide the essential information to allow processors to carry out suitable modifications and installations at their own sites to improve some aspects of their processing performance. As each processing site has unique design and construction features the information in this kit should be used as a guide only. Some modifications from this kit, to ensure the successful application at individual sites, are likely. No warranty is given on the outcome of the use of this kit or the information it contains. The prototype unit was constructed and installed at a Queensland domestic abattoir that had previously not used a downward hide puller. The unit has successfully operated for some 2 years without problem, at a rate of up to approximately 60 bodies per hour. Abattoirs will require, or should have access to, reasonable engineering skills and facilities to be capable of constructing and commissioning the Rotating Drum Downward Hide Puller. Description The Rotating Drum Downward Hide Puller consists of a hydraulically powered unit that rotates a drum that is attached to a carriage that can travel vertically. Operators stand on enclosed platforms mounted to either side of the drum carriage and travel vertically with the drum. This allows the operators to apply any necessary manual intervention, using conventional knives or air knives, as the hide is released from the carcase surface. DIY Kit # 4 – Rotating Drum Downward Hide Puller The Rotating Drum Downward Hide Puller is used with on-rail beef dressing for an hourly capacity of up to 80 head of cattle. Maximum capacity is dependent on the slaughterfloor layout and possible labour utilisation. The equipment is designed for retrofitting to on-rail dressing systems and for installation in new slaughter lines. The height of the operators’ stands, in relation to the carriage can be manually varied to the desired position for each operator. The stands, in the prototype design, are fixed horizontally but can be modified, if required, with the fitting of air rams to the underside of the platforms. This will give horizontal movement in relation to the drum carriage. Towards the bottom of the vertical movement the operators’ platforms move on slides so that the drum can be lowered as close to the floor as possible, without the platforms touching the floor. Downward hide pulling has been proven to be a more hygienic technique than manual flaying of the hide or upward hide pulling. Downward hide pulling requires less manual contact with the hide than manual flaying. During upward hide pulling the hide can flick contamination onto the cleared surface or in extreme circumstances can fall back against the carcase. This is far less likely to happen with downward hidepulling as the hide falls away from the carcase. The near side of the drum is located at approximately 900 mm from the centre line of the beef rail to ensure the correct combination of vertical and horizontal pull. This ensures the most effective hide removal. The drum is fitted with two chains with slip links to grip the hide. The slip links are used to form a noose in the end of each chain. The freed hide from each hind leg is passed through the noose and trapped by the tightening chains. Rotation of the drum is such that the near side, that nearest the carcase, moves downward pulling the hide away from the carcase as well as down. Processors currently dressing on a rail using manual flaying or upward hide pulling can install the Rotating Drum Downward Hide Puller at the position where hide pulling currently occurs. Some modification to pre-work is necessary with an overall reduction in the level of pre-work required. 1 Upward hide pulling also creates a carcase hygiene issue. When the hide is at its last point of contact, at maximum elevation, it can distribute dirt particles from the outer surface of the hide down over a large area of the exposed carcase surface and surrounding area. The removal of the hide is controlled with foot controls that the operator uses to adjust the rate of vertical movement and the rate of drum rotation. Effective hide pulling is managed by controlling the combination of these two movements. At the end of the hide pulling operation the hide is released automatically from the slip links by reversing the rotation of the drum. Changing upward hide pulling to downward hide pulling results in improvements in: Effective Operation • Improved carcase hygiene Care must be taken when pulling the hide over the animal’s head so that the puller does not apply too much force to the body. Excessive longitudinal pull can cause separation of the vertebrae in the back and potential downgrading of the carcase. The operators can achieve reduction of force by intervening when the hide is pulled over the head or by head removal prior to pulling on large cattle. • Increased productivity Materials The prototype constructed, installed and still in operation in Queensland used the following materials. Prices are at 1998 costs when installed. Item Materials Hydraulic Unit inc; motor assembly, power unit, cylinder & valves Hydraulic Swivel Assembly 205 mm x 40 mm dia x 50 mm Polyethylene UHMW 1000 grade Stainless steel flanges 500 mm dia OD/150 mm dia ID x 12 mm 500 mm dia OD/75 mm dia ID x 12 mm 335 mm dia OD/273 mm dia ID x 12 mm If it is necessary to maintain a high force on the hide puller to pull the hide over the head, the number of bodies with separation of vertebrae can be reduced with the implementation of stiffening probes. These are probes that apply an electrical current to the carcase in the region of the lower back. The electrical stimulation stiffens the muscles of the back supporting the vertebrae against separation. Stimulation of this nature is particularly effective when low voltage carcase stimulation has not been applied immediately after slaughter and prior to hide pulling. Quantity Cost 1 $10,000.00 1 4 $ $ 1 1 2 $ 124.00 $ 124.00 $ 146.00 Item Length (mm) Area (mm) Stainless steel sections 75 x 10 flat bar 600 40 dia shaft 750 50 dia shaft (inside diameter of 40) 460 Perforated plats/Tread plate 1200 x 700 250 NB pipe sch 40 800 Mild steel sections 150 x 50 x 5 RHS 2,300 150 x 100 x 6 RHS 1,600 230 PFC 10,100 150 PFC 4,100 75 x 75 x 4 RHS 4,800 65 x 65 x 6 RHS 4,100 65 x 65 x 6 Angle 8,800 50 x 50 x 6 Angle 2,700 32NB pipe 4,800 25NB pipe 4,800 100 x 4 flat bar 4,000 75 x 6 flat bar 400 60 x 10 flat bar 360 50 x 10 flat bar 240 40 x 10 flat bar 720 75 x 10 flat bar 3,450 10 mm mild steel plate 1,100 x 100 12 mm mild steel plate 120 x 240 16 mm mild steel plate 1,230 x 275 20 mm mild steel plate 1,420 x 355 70 mm block 220 x 240 50 mm block 130 x 240 Item Length (mm) Area (mm) 40 mm block 40 x 600 50 mm x 50 mm square bar 110 40 mm round bar 2900 40 mm nylon square 1200 Stainless steel shackling chains 3900 Total Suppliers: Applied Hydraulics & Lubrication; Brisbane (hydraulic equipment) Steelmark – Eagle & Globe Midway Metals Ludowici Rubber & Plastics; Brisbane (polyethylene, nylon) Beaver Sales; Brisbane (chain) Suitable stiffening probes are commercially available and can be fitted to this design. Benefits Several advantages have been identified from using the Rotating Drum Downward Hide Puller when compared to both manual flaying and upward hide pulling. Benefits against manual flaying Manual flaying requires a very high skill level for effective hide removal without damaging both hide and carcase. Mechanical hide pulling reduces the physical nature of this task and the level of knife work required. The use of air knives further reduces the accuracy that is required to, safely and effectively, assist the separation of the hide and the carcase. Hide to flesh contact is difficult to eliminate during manual flaying. Even when the operator’s skill level is high it is difficult not to damage the hide with cuts or scores. Selvage is often lost from the carcase. Altering a manual flaying system to a downward hide pulling system results in benefits in the areas of: 350.00 620.00 Cost $ $ $ $ 21.00 45.00 15.00 430.00 $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ $ 75.00 101.00 542.00 141.00 99.00 116.00 77.00 23.00 44.00 34.00 37.00 3.00 4.00 2.00 5.00 42.00 17.00 6.00 84.00 153.00 62.00 25.00 Cost $ 17.00 $ 4.00 $ 65.00 $13,653.00 • Occupational Health and Safety. • Increased productivity. Drawings • Improved carcase hygiene. The appended engineering drawings show: • Increased yield remaining with the carcase S0360101 Hide puller arrangement • Greater hide value through less damage S0360102 Hide puller main carriage S0360103 Hide puller carriage roller guide arm S0360104 Hide puller drum S0360105 Hide puller support frame S0360106 Hide puller platforms S0360108 Hide puller chain requirements Benefits against upward hide pulling Upward hide pulling requires more pre-work than downward hide pulling. When upward hide pulling the forelegs have to be restrained by chains and hooks that are fitted through the tendons and attached to a post. These chains and hooks must be sterilised between carcases adding extra labour and time to the hide pulling operation. 2 3 4 5 6 7 8 9 10 11 Video presentation Approximately 7.8 minutes of the hide puller in operation showing the important features of design, construction and operation are provided on the Meat and Livestock Australia Technology Transfer DIY Kits’ Support Video. Footage relevant to the Rotating Drum Downward Hide Puller Unit DIY Kit is approximately located between VCR real time counter units 22:00 to 27:50. Acknowledgments Meat & Livestock Australia have prepared this kit with support from the Australian Meat Processors Corporation. Equipment design & project management Australian Meat Technology Pty Ltd Equipment construction, installation, commissioning and operation Killarney Abattoir, Killarney, QLD Contact Processing and Product Innovation Meat and Livestock Australia Tel: (02) 9463 9166 Fax: (02) 9463 9182 165 Walker Street, North Sydney NSW 2060 Tel: (02) 9463 9333 Fax: (02) 9463 9393 www.mla.com.au Published November 2000 ISBN: 1 74036 816 9 © Meat and Livestock Australia MLA makes no representation as to the accuracy of any information or advice contained in this document and excludes all liability, whether in contract, tort (including negligence or breach of statutory duty) or otherwise as a result of reliance by any person on such information or advice.