Mahindra CSR10_1 to 5 - United Nations Global Compact

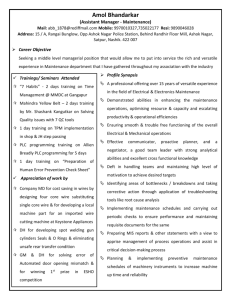

advertisement