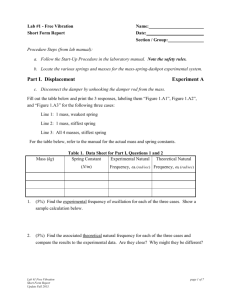

Lab Instruction

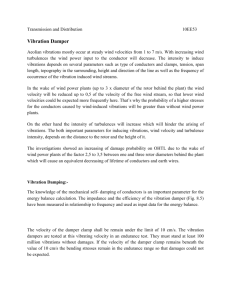

advertisement

2142-391 Engineering Mechanical Laboratory Vibration of Beam Nopdanai Ajavakom Chanat Ratanasumawong 1. Introduction Vibration is the branch of engineering that deals with repetitive motion of mechanical systems. A few examples of vibration problems are the wing fluttering, the response of an engineering structure to earthquakes, the vibration of an unbalanced rotating machine, the time response of the plucked string of a musical instrument, and the quality of ride of an automobile or motorcycle. Most practical vibrating systems are very complex, and it is impossible to consider all the details for a mathematical analysis. Only the most important features are considered in the analysis to predict the behavior of the system under specified input conditions. Often the overall behavior of the system can be determined by considering even a simple model of the complex physical system. Thus the analysis of a vibrating system usually involves mathematical modeling, derivation of the governing equations, solution of the equations, and interpretation of the results. 1.1. Motivation In general the vibrating system is simplified to a simple model including three basic elements. Three basic elements are 1) the element restoring or releasing kinetic energy that is a mass or a mass moment of inertia, 2) the element restoring or releasing potential energy that is an elastic component or a spring, and 3) the element dissipating energy that is a damper. To analyze the vibration problem, the quantities of these elements must be known. Although the mass and the spring stiffness of the vibrating system are able to determine easily by a scale or by static test, the damper are difficult to measure. To determine these quantities, the dynamic measurement is required. For our study, we simplify the wing fluttering problem into the vibration of rigid beam. To predict the behavior of beam vibration, we have to know the quantities of three basic elements: the mass moment of inertia of the beam, the stiffness of spring and the damping of the dashpot, put them in the governing equation and solve for response. Some static and dynamic methods to determine these quantities are studied and the measurements are also done. 1.2. Objective/Problem Statement Broad description of the family of systems and experimental conditions We shall focus on the single-DOF system, and will test both free vibration case and forced vibration case. Specific aspects of interest in these systems The aspect of current interest is the quantities of the mass moment of inertia of beam, the elastic stiffness of spring and the damping coefficients of dampers. Problem Statements Determine the time response of the displacement at the end of the beam at various conditions. [Plot displacement VS time] Then find the quantities of the basic elements as well as other important vibration-related parameters. 2. Approach 2.1.General Measure and plot the time response of the displacement, then calculate the other dynamic parameters using theoretical relations. 2.2.Brief Description and Diagram of Apparatus The diagram of apparatus is shown in Fig.1. The apparatus consists of a beam that at its one end is hinged on a trunnion attached to the vertical frame. The beam is hung to lie horizontally with a spring that can be changed to vary the stiffness. A damper can be added into the system by attaching a dashpot to the beam. The damping coefficient of the damper can also be varied by adjusting the diameter of oil orifices inside the dashpot. For forced vibration experiment, an unbalance motor will be attached to the beam. The rotational speed of the motor can be adjusted by an inverter. The vibration of beam can be measured by the displacement sensor attached close to the end of the beam, and then the measured signal is sent to a computer to be processed further. 2.3.Brief Description of Measurands and Measurement Instruments The data measured from the displacement sensor are sent to the real-time controller unit to process the signal and subsequently sent to demonstrate and collect at PC. 3. Experimental Results 3.1.Graphical Results Displacement VS time and Displacement VS frequency plots. 3.2.Questions Pertaining to Experimental Results 3.2.1. What is the frequency of the oscillation? 3.2.2. What are the inertia, the stiffness constant, and the damping ratio of the system’s elements and the natural frequency of the system? How can you find them? 3.2.2. If you know the dynamic parameters of the system, how can you predict the response of the system with another initial conditions and/or forcing functions? References and Recommended Readings 1. Daniel J. Inman, Engineering Vibration, Prentice Hall. 2. William T. Thomson and Marie Dillon Dahleh, Theory of Vibration with Applications, Prentice Hall. 3. Singiresu S. Rao, Mechanical Vibrations, Prentice Hall. 4. Kelly J., Fundamentals of Mechanical Vibrations, McGraw Hill. 5. ESSOM, Instruction manual MM 320 Universal vibration apparatus. Frame Unbalanced motor Spring Displacement sensor Dash pot Beam Control box Figure 1 Universal Vibration Apparatus 2145-392 Engineering Mechanical Laboratory Vibration of Beam I. Theoretical background 1. Free Vibration The single-degree of freedom beam system is generally modeled as shown in Fig.2. IO is the mass moment of inertia of beam and motor, c is the damping coefficient, and k is stiffness of the spring. The equation of motion of this system can be derived by using Newton’s second law of motion, and written in Eq.(1). I O ca 2 kb2 0 (1) Equation (1) can be written in the form of natural frequency and the damping ratio as shown in Eq.(2). 2 2 0 n n (2) Where natural frequency n kb2 IO , and damping ratio ca 2 / 2 IO kb2 The solution of Eq.(2) that shows the response of the torsional system varies due to the value of damping ratio . The responses of vibration corresponding with Eq.(2) can be separated into 3 cases that are underdamped motion ( 1 ), overdamped motion ( 1 ) and critically damped motion ( 1 ). These responses can be shown by Eqs.(3)-(5). (t ) Ae nt (sin( d t )) Underdamped motion: where (3) d n 1 2 (t ) e n t (a1e n 1t a2e n Overdamped motion: Critically damped motion (t ) (a1 a2t )e nt 2 c o 2 1t ) (4) (5) k a am b L Figure 2 The single-degree-of-freedom beam system The constants A, , a1, and a2 can be determined, if the initial condition and/or boundary condition are specified. 2. Logarithmic decrement The damping coefficient or, alternatively, the damping ratio is the difficult quantity to determine. One of the common ways to determine the amount of damping is to measure the rate of decay of free oscillations. The larger the damping, the greater will be the rate of decay. The logarithmic decrement is defined as the natural logarithm of the ratio of any two successive amplitudes (see Fig.3). The expression for the logarithmic decrement then becomes ln (t ) Ae n t sin( d t ) ln (t T ) Ae n (t T ) sin( d (t T ) ) (6) Figure 3 Underdamped response used to measure damping where T is the period of oscillation. Since the values of sines are equal when the time is increased by the damped period T, the preceding relation reduces to ln e n t e n (t T ) ln e nT nT (7) By substituting the damped period, T 2 ( n 1 2 ) , the expression for the logarithmic decrement becomes 2 (8) 1 2 Solving this expression for yields 4 2 2 (9) Peak measurements can be used over any integer multiple of the period to increase the accuracy over measurements taken at adjacent peaks. The expression of the logarithmic decrement corresponding to n-period peak measurement is shown in Eq. (10) 1 (t ) ln n (t nT ) (10) 3. Forced Harmonic Vibration Consider the beam system shown in Fig.2, if this system is excited by an unbalance force from the motor F0 cos t , the differential equation of motion becomes I O ca 2 kb2 am F0 cos t (11) The solution to this equation consists of two parts, the free vibration response as shown in Eqs.(3)-(5), and the force vibration response of the same frequency as that of the excitation. The force vibration response is observed to be in the form p cos(t ) (12) Where is the amplitude of oscillation and is the phase angle of the displacement with respect to the exciting force. The total solution of Eq.(11) is the sum of free vibration response and force vibration response and is shown in Eq.(13) for the case of underdamped motion. (t ) Ae n t (sin( d t )) cos(t ) (13) Note that the term of free vibration response can be changed to be overdamped response or critically damped response depended on the value of damping ratio of the system. From Eq.(13), it is evident that for the large values of t, the term of free vibration response approaches zero and the total solution approaches the force vibration response. Thus the term of force vibration response is called the steady-state response and the term of free vibration response is called the transient response. Consider the steady-state response shown in Eq.(12), the Amplitude and phase can be found by substituting Eq.(12) into the differential equation of motion Eq.(11). The Amplitude and phase are shown in Eqs.(14) and (15). and am F0 (kb I O 2 ) 2 (ca 2) 2 2 tan 1 ca 2 kb2 I O 2 (14) (15) Equations (14) and (15) can be expressed in the nondimensional form as shown in Eqs.(16) and (17) kb2 am F0 Figure 4 Plot of the normalize amplitude and phase of the steady-state response of a damped system versus the frequency ratio kb2 1 2 am F0 (1 r ) 2 (2r ) 2 2 r 1 r2 where r is the frequency ratio r n . and tan 1 (16) (17) The plots of Eqs.(16) and (17) for several values of the damping ratio are shown in Fig.4. Note that as the driving frequency approaches the undamped natural frequency (r 1) the magnitude approaches a maximum value for the cases that are light damping. Also note that at this point, the phase shift crosses through 90º. This point is defined resonance point for the damped case. II. Details of apparatus The apparatus may be adjusted into a variety of configurations to study the effect of mass moment of inertia, spring stiffness and damping coefficient to the vibration of beam both in the case of free vibration and force vibration experiment. For force vibration, the rotational speed of unbalance motor can be adjusted to excite the beam to vibrate at wide frequency range. The system consists of three subsystems: 1. The main apparatus shown in Fig. 5. It is comprised of the beam, spring, adjustable damper, unbalance motor, and the displacement sensor. The positions that attached spring, damper and measuring vibration can be adjusted, and spring can be changed to vary the stiffness. 2. The control box that is used to convert analog signal to digital signal and control the rotational speed of the motor. 3. The system interface software, which runs on a PC in windows XP. The program is the user’s interface to the system and supports data acquisition, plotting, system execution commands, etc. Here the program “Freedamp” is used in both free vibration experiment and forced vibration experiment. Figure 5 Universal Vibration Apparatus Some important specifications 1. The total sampling rate of all channels must not be higher than 48,000 samples/sec. The number of sampling rate is divided equally for each channel, if multiple channels are used. 2. The sensing range of the displacement sensor is between 30 to 300 mm. The Power LED (left LED) must be green and the output LED (right LED) must be yellow in normal operation. 3. Sensor sensitivity is approx. 70 mV/mm To start up Turn on the PC Turn on the power to the Control Box To shut down Turn off the power to the Control Box Turn off the PC Safety Precautions 1. Be sure to firmly tighten (but not overtight) the bolts that fasten the beam, damper, and the motor. 2. Stay clear of and do not touch any part of the mechanism while it is moving, especially the running motor. 3. Do not run the motor with too high speed. 4. Do not drive the motor with excessive power. III. Experiments 1. Free vibration This section gives a procedure for identifying the system parameters. The approach will be indirectly measure the spring stiffness constant, and damping constants by making measurements of the movement of the beam. The mass moment of inertia of the system can be determined by weight the beam and the motor, and measure beam dimensions, and then the mass moment of inertia of the beam can be calculated. Procedures 1. Set up the apparatus to be the same as shown in Fig.2. Be careful to adjust the beam to lie horizontally. 2. Set the positions of the attached damper “a”, spring “b” and motor “am” according to the instructor. 3. Power up the system and open the system interface program “Freedamp”. 4. Measure the length of the beam, the weight of the beam, and the weight of the motor. Input the distances that attach spring and damper and the masses of beam and motor in the “figure” tab. 5. In the “signal measurement” tab, input the data into the following windows 5.1 Time to wait before get signal (s): input delay time from press “Get signal” button until measurement start. [0 s] 5.2 Sample rate: input the number of samples measured in one second. [200+] 5.3 Time of samples (s): input measured time [4 s] 5.4 Number of samples: Number of measured samples (= Sample rate Time of samples) 6. 7. 8. 9. 5.5 Time out (s): The time that the interface program still actives. If there are not any responses until the setting time is passed, program will becomes inactive. 5.6 Elapsed time: The time before measurement start. Press “Get signal” button. Displace the end of the beam down approximately 30 mm and then release. Be careful that the vibration of beam is completely collected and recorded. Plot the beam time response (displacement versus time graph). Save the raw data text or excel file format. Determine the damped natural frequency of beam d by choosing several consecutive cycles and dividing the number of cycles n by the time taken to complete the cycles tcycles . Td t cycles tn t0 n (18a) n 2 d (18b) Td 10. Determine the logarithmic decrement by measuring the reduction from the initial cycle amplitude 0 to the last cycle amplitude n for the n cycles measured in step 10. Using relationship: 1 ln 0 n n 11. Determine the damping ratio from (19) . 4 2 2 12. Calculate the natural frequency of the system using d n 1 2 (20) 13. Change the position that the damper is attached to the beam “ b ”. 14. Questions and Discussion: Do you think whether the values of d , , n change after the position of the damper changed? If so, how do they change (increase or decrease)? 15. Redo steps 7-13 to obtain Td , d and n . Discuss the any differences found in the new results compared to the previous ones. 16. Now you can calculate the mass moment of inertia of the beam and motor system I O and stiffness of spring k from (solving two equations for two unknowns): n kb2 and n IO kb 2 IO Then the damping coefficient is c 2 I 2 I 0n and c 0 2 n . They should be very 2 a a close to each other. 17. Compare the experimental mass moment of inertia of the beam and motor system I O 1 to the theoretical one from I O mb l 2 mm a m2 . 3 18. Questions and Discussion: Can you suggest an alternative approach to find the stiffness of the spring? Hint: The approach uses static displacement of the beam. Use the approach to find the stiffness of the spring and compare them to the one from the previous experiment. 2. Forced Vibration This section will study the response of the system due to harmonic force input from the unbalance motor. The frequency of harmonic force is adjusted by varying the rotational speed of the motor. Procedures 1. Set up the apparatus to be the same as shown in Fig.2. Be careful to adjust the beam to lie horizontally. 2. Set the positions of the attached spring, damper and motor identical to the first experiment. 3. Open the system interface program: “Freedamp”. 4. In the “figure” tab, input the distances that attach spring and damper, the length of beam, the masses of beam and motor, the stiffness of string k, and the damping coefficient c. (k and c are known from the former experiment) 5. In the “signal meas” tab, input the data into the windows 6. Start motor, and adjust to operate at low rotational speed. 7. Wait for the system become steady state, and then press the “Get signal” button to start to collect the data. 8. Save the collected data into a file. 9. Plot the displacement vs time, and collect steady state output amplitude. 10. Increase rotational speed of motor and repeat steps 7-9 to get a total of at least 10 points. Make sure that the range of speed of the motor covers the natural frequency of the system. 11. Change the damping coefficient by adjusting the orifice area inside the dashpot, and repeat steps 7-10. 12. Plot the steady state amplitude vs frequency to see the amplitude response of the system. Then, determine roughly at what frequency the amplitude of the response is highest. Is it near the natural frequency? Discuss. 13. Also plot the theoretical graph using the parameters obtained from free vibration experiment. 14. Discussion: Compare three graphs and discuss on the differences.