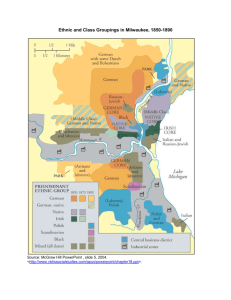

Cleveland from Startup to the Present

advertisement