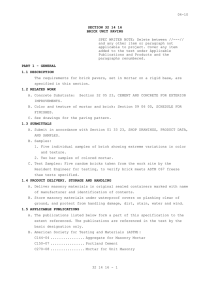

MSE 220

advertisement

MSE 220 Chapter 4 Masonry Problems 2, 3, 4, 5, 7, 8, 11, 12, 17, 18, 19 2. Two types of masonry units are hollow and solid. Types of masonry units include brick, tile, stone, glass block and concrete block. 3. Hollow masonry units have a net cross sectional area in every plane parallel to load bearing surfaces less than 75% of the gross cross sectional area in the same plane. Solid units have > 75%. 4. Raw materials to manufacture brick include burned clay, but may include solid blocks made of concrete and sand-lime. 5. Three grades of brick are SW (severe weathering), MW (moderate weathering) and NW (negligible weathering). 7. Portland cement is a mixture of limestone and clay, and, after processing, is made up of dicalcium silicate, tricalcium silicate, tricalcium aluminate and tetracalcium aluminoferrite. Masonry cement is similar to Portland cement in that it contains Portland cement, Portland-pozzolan cement, natural cement, slag cement, Portland blast-furnace slag cement or hydraulic lime, but may also include hydrated lime, limestone, chalk, shells, talc, slag or clay. 8. Adding lime to mortar increases is plasticity, ability to retain moisture and workability. 11. Four types of standard mortar are M, S, N and O. Type M has the lowest hydrated lime content, while O has the highest. 12. “Flow” is the % increase in diameter of a conical frustrum of mortar 4” in diameter at its base after the flow table has been dropped through a height of ½” 25 times in 15 seconds. 17. Two properties that determine the compressive strength of masonry are the compressive strength of the units and the mortar mix proportions. 18. 1500 psi. See Figure 4.26. 19. Efflorescence is the leaching of soluble salts in brick leading to white patches on the face.