Structural and Manufacturing Design of a Research Unmanned

advertisement

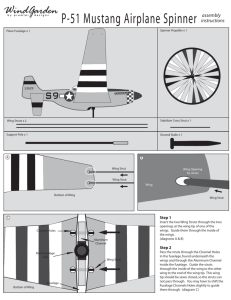

Structural and Manufacturing Design of a Research Unmanned Aerial Vehicle Piergiovanni Marzocca, Daniel Valyou, Jordan Janas Department of Mechanical and Aeronautical Engineering In order to facilitate numerous airborne research opportunities, it was proposed to build a multirole aircraft, capable of operating as either an unmanned aerial vehicle (UAV) or as an R/C aircraft as defined by the FAA. A research UAV must have sufficient payload capacity for an avionics package as well as the research payload. Such a requirement defines a UAV which has high wing loading, a large powerplant, high endurance, a robust structural design, and most importantly a low empty weight. However a UAV designed for research should have low initial and maintenance costs, as researchers often have a limited budget. To meet these design criteria novel construction materials and methods are explored, with the goal of manufacturing a lightweight UAV capable of carrying a large fuel load and payload, with a low initial cost and even lower replacement cost. Structurally this is accomplished by using a semi-monocoque structure for the fuselage and wing consisting of fiberglass and foam composite sandwich panels. In high stress fuselage areas (landing gear mounts, firewall, and wing joints) carbon fiber sandwich panels with a core of either rohacell or honeycomb are incorporated. The wing spar is carbon fiber tube, and carries through the fuselage. The design goal for the manufacturing process is to make the process as automated as possible to enable student builders to fabricate any requisite replacement parts. All fuselage, wing, and tail skins are vacuum formed in reusable female molds. All carbon sandwich panels are cut out on a CNC machine in-house to maximize dimensional accuracy and minimize waste. The wing and tail molds are CNC machined from machinable polyurethane panels. The fuselage molds are fiberglass castings of a CNC machined fuselage plug. Maximizing the use of reusable female molds and CNC cut parts facilitates the fabrication of replacement parts and subsequent UAVs at low cost. 2010, Aeronautical Engineering, Honors Program, Piergiovanni Marzocca