Open Access version via Utrecht University Repository

advertisement

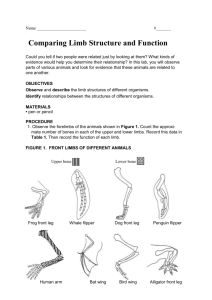

Title; Pressure distribution in the metacarpal joint during midstance in gallop. Introduction The horse racing industry in New Zealand is a major part of the economy. Export is mainly to Australasia and generates the most money. The costs associated with lameness in the racing industry and the growing interest from the public in welfare of the horses raises the awareness about issues relating to the health of racehorses. [1] The primary reason for the elimination of horses is lameness originating from the musculoskeletal system. In the race horses the primary injury is chondylar fracture associated with palmar osteochondral disease (POD). So quantity and quality research on biomechanical action of fetlock joint needs to be conducted to understand the loads in this joint and reason(s) for failure to withstand these pressures. Mechanical testing provides the mechanism to do this. Anatomy The distal part of the third metacarpal bone, the proximal part of the proximal phalanx, the joint capsule and the suspensory apparatus form the metacarpalphalangeal (fetlock) joint. The suspensory apparatus includes the suspensory ligament, two proximal sesamoid bones and the ligaments of these sesamoid bones. The metacarpal phalangeal (MCP) joint is a composite joint, acting like a hinge joint. Two segments, the proximal articular surface of the first phalanx and the trochlea of the third metacarpal bone, connected together by strong collateral ligaments form the base of the joint. It allows optimal flexion and extension (movement in one plane) but minimal abduction, adduction or rotation. The MCP joint also articulates with the two proximal sesamoid bones situated at the palmar aspect of the joint. The sesamoid bones are imbedded in the interosseus ligament. There are two pouches to the joint capsule, the dorsal and palmar pouch. In the standing horse a lot of weight presses down on the fetlock joint. The suspensory apparatus prevents excessive dorsal flexion. It consists of the cruciate, oblique and straight sesamoid ligaments. The direction in which the proximal phalanx can move differs little from that of the third metacarpal bone. Although there is a limited amount of lateral deviation from the sagittal plane when the limb is flexed entirely. [2] Figure1 a,b,c Pathology A frequently observed problem in Thoroughbred racehorses in New Zealand are abnormalities of the bone and cartilage structure in the MCP joint as seen in osteoarthritis and palmar osteochondral disease. POD is believed to be a biomechanical disorder caused by high intensive exercise in which the joint is chronically overloaded resulting in localised trauma.[3] It is believed that the lesions at the dorsal articular margin of PI are caused by combination of;[3] intermittent character of the load applied to the joint high values of load on the articulating area during performance small articulate surface area large range of motion of the joint. Musculoskeletal injuries occur in 97% of the cases presented with lameness and in particular the lower limb up to the carpus or hock in the fore- and hind limbs.[1] The linear relationship between POD and the dorsal impact injuries suggest evidence that POD is associated with cyclic repetitive overextension of the fetlock joint.[4] Lesions The lesions found regularly in the fetlock joint are small ovoid defects, but they vary in severity, from discolouration of the subchondral bone when the overlying cartilage is normal to collapsing of the subchondral bone with ulceration of the overlying cartilage. The lesions are present in the palmar and plantar articulate surface, 5-8 mm proximal to the transverse ridge and 3-15 mm medial and lateral of the transverse ridge.[4] These changes in the MCP joint are quite often the cause of poor performance rather than actual lameness. It is difficult to diagnose because only the most severe abnormalities can be seen on radiographic imaging and horses are inconsistent in there presenting the lameness according to the severity of the lesions. With arthroscopic examination the predilection places are impossible to see. So when diagnosed it usually is too late and it has become a chronicle joint disease.[3] There is a significant linear relationship between the grade of POD and the grades of visible injuries to the condyles. These include wear lines, cartilage ulceration and dorsal impact injuries. The relationship between POD and linear fissures was significant but not linear. [4] There does not appear to be differences in the graduations between limbs or lateral or medial sides of the joint (Barr et al.) This is peculiar because horses gallop mostly in the same direction and as the leading forelimb is last to leave the ground it is subjected to the highest amount of pressure.[5] The statement is contradicted by Pool who says that lesions are more common in front legs.[3] Rooney claims there is a link between the direction of galloping and the predilection of lesions in the inside leg.[6] Frequently seen consequences of the lesions in the MCP joint are condylar fractures, with as most common site the lateral condyle of the distal articulate surface of the third metacarpal bone. The fractures are much alike in pathological morphology. [7] A lot of different influences play a role in the pathology of bone and soft tissue injuries. To summon the risk factors for every type of MSI is impossible. But in several studies [1, 4, 6, 8-14] the age of the horse, management, racing distance and training method are given as risk factors. Elastic strain energy[12] [15] Locomotion of the horse is supported by storing and utilization strain energy generated by the tendons in the lower limb. Because larger animals can leverage substantial ground reaction forces (GRFs) they can store strain energy in their elastic tissues. This energy can power body movements later in the gait cycle and thus reduce the metabolic energy cost. For example the hyperextension of the MCP joint causes the flexor tendons to expand, building up energy which is released if the gait cycle continues. The joint works as a passive spring. The structures that facilitate this elastic strain energy are subjected to high forces that can cause injuries in these sites. Flexor tendons that cover the MCP joint are exposed to the highest forces, especially the interosseus muscle, superficial digital flexor and deep digital flexor. The consequence of this is that out of all the joints in the forelimb of a horse, the metacarpalphalangeal joint endures the highest contact forces. When the limbs are subjected to higher speeds, as with the racehorses, the strain energy storage may have bad consequences. The high prevalence of lameness originating at the MCP joint suggesting that this site suffers under high speed performances. Ground reaction force (GRF) The fetlock joint is extended in the normal standing position and will extend further when greater loads are applied. In gallop the maximal extension occurs in midstance, at this moment the full body weight of the horse is transmitted on to the ground.[9] As a counter force the GRF is extended by the ground on an object placed upon it. This means it is equal in magnitude and opposite in direction to the force that, in this case the horse exerts on the supporting surface through its hoof. During every stride of a horse there are two phases. The stance phase is the time the hoof makes contact with the ground and so can strike off to keep in motion. In the swing face it does not. For the front limbs the mean duration of the stance phase is 131 milliseconds at a speed of 9m/s-1 (fast canter) and 77 milliseconds at 17 m/s-1 at gallop. The mean duration of the swing phase was 364 milliseconds at 9 m/s-1 and 342 milliseconds at 17 m/s-1. Between the leading and non-leading limb no significant difference was found. The GRF peak forces recorded for the front limbs at 17 m/s-1 were 24.7 N per kilogram body weight. At a body weight of 500 kg, a force of 12.35kN is applied to one front limb. The back limbs in comparison, with a peak force of 15.3 at 17 m/s-1, get a force of 7.65 kN.[16] This shows a much higher force during gallop in the front limbs and contributes to the lameness found in these limbs. Pressure During the movement of the limb of a horse the location and amount of pressure differ on the joint surface. According to the large range of motion of the MCP joint it has a relatively small cartilage surface. In mid-stance position this leads to a shift of the load from a central to a more proximaldorsal position on the proximal phalanx. [12] In walk the pressure during and after mid-stance of the limb where significantly higher than those before. Loading demonstrated a biphasic pattern in the entire joint except for one location; halfway along the sagittal groove. Here a linear increase of pressure during the movement of the stance phase at walk was found. Medially the pressure was significantly higher than lateral from the sagittal groove.[17] If load applied to the MPC joint exceeds the absorbing capacity of the tissue the articular cartilage will be damaged. When this threshold is exceeded, the collagen network is damaged and can no longer endure even normal forces.[18] Because of the loss of function it can lead to different, mostly severe lesions. Larger stress gradients most likely are the result of the large difference in load distribution on the central groove compared to the other locations in the joint at the end of the stance phase. The difference in the distribution of pressure inside the joint could be related to the pathogenesis and location of lesions found in the MCP joint in race horses. The aim of this project was to examine where the highest joint pressure occurs within the MCPJ and if on these sites the lesions described in other articles are the most severe. The hypothesis tested was that the worst lesions in the metacarpal phalangeal joint are located at the sites with the highest pressure. The highest pressure develops when the joint angle is small. Materials and Methods Specimens Left limbs were collected from 6 thoroughbred horses euthanized for reasons other than orthopaedic problems. The limbs are provided with history information about age, training level, number of races and reason for euthanasia. After collection the limbs where frozen (-20° C) within 24 hours to keep them as fresh as possible. Before testing a limb it needed to be cut at a right angle to the long axis of the humeral bone and thawed for 24 hours at environmental temperature, always keeping them moist. The cut was made by a band saw just distally from the deltoid tuberosity of the humerus, the olecranon kept intact. Every hoof was trimmed by a single farrier to uniform the surface and to rule out the influence of an irregular surface on fetlock joint kinematics. Placement in Material testing Machine (MTM) A pin was inserted into the humerus and trough the humero-radial joint to fixate it at a 230-235°[14] angle, mimicking the weight barring mid-stance gallop position. A hole was drilled into the marrow cavity of the humerus and a 120 mm long and 13 mm wide pin was inserted to achieve the fixation. At the end of the pin there was a rim so the force applied to the pin was spread equally over the surface of the humerus. On top of the pin was a metal boll that fitted in to a socket attached to the MTM. In this way cranio-caudal movements of the limb where still possible which are needed to keep the loading procedure as close to the in vivo situation as possible. At the bottom of the machine a hoof plate was installed to make the surface absolutely horizontal. The limbs where kept moist at all times so the movements where as close to the in vivo situation as possible. Inserting pressure sensitive film FuijiFilm Prescale medium range (10-50 MPa) pressure sensitive films where used in this research. Cut to fit inside the joint they were sealed in plastic to keep them waterproof. The film had to be fitted to each joint, because the joint differ in size. To measure the pressure inside the MCP joint pressure sensitive films where inserted from the distal side of the MCP joint. A ±50 mm incision cut through the digital extensor muscle and the joint capsule, leaving the lateral and medial collateral ligaments intact. Inserting the films was very difficult; one person pulling the upper part of the limb and another person pulling and bending the lower part of the limb so a third person could insert the pressure film. This needed to be done very carefully; not to fold the film or damage the joint surface. Measurement of the joint angle Joint angles measured mimicking the midstance of the lead limb in gallop. Markers need to be placed at 6 places; Proximal and distal at the third metacarpal bone. To do this a 30mm screw was drilled into the MCIII with a wooden stick at the head. On the ends of this wooden stick two markers where placed; vertical segment parallel to the bone. Proximal and distal on the proximal phalanx. The markers where glued to the bone. To be safe if any strange results turn up we also want to know the angle of the hoof joint. So markers are placed at the top and on the tip of the hoof, following the angel of the hoofwall and so that of the distal phalanx. The skin was dissected from the limb from the hoof until just above the carpal joint to exclude skin displacement which would give measurement errors. The markers are placed in a way they will not move during testing. It was very important to do the preparation in a certain order, otherwise the markers would get torn or displaced when inserting the pressure sensitive film. The pressure film was inserted first, then the limb was placed in the machine and finally the markers where placed so they were in the right plane. Calibration of the pressure sensitive films The pressure sensitive film needed to be calibrated to know which red coloration relates to which pressure. The method described by Den Hartog 2008[17] is used. Force was applied to a pressure algometer (FDK60) with a custom made stainless steel mal and a titanium stamp with tip. The mal could be attached to the algometer by means of a screw-wire pin. The tip could move freely (1mm margin) inside the mal. This pressed on the pressure film using a hand-assisted drill. The maximum force that could be applied to the algometer is 30 kg. To generate a pressure of 50 MPa (maximum the film could measure), the surface pressing on the film needs to be very small When the tip has a diameter of 5 mm2 and the maximum force of 30 kg is applied to this area a pressure of 60 MPa will be generated, enough to calibrate the pressure sensitive film. The pressure film needs to be on a horizontally and even surface. The standard was made by applying different loads (calculated in advance) to the tip and so generating different pressures on the pressure sensitive film. This will create different colourations. Unfortunately this method did not work. The stamp did not made a uniform circle, some of the edges did not colour on the pressure film. A lot of alterations to where made to the stamp, mall and underlying surface to get the uniform circles. This did not work. The alternative was to use the standardisation from the FujiFilm, a leaflet with the different colour ranges of the pressure film. These colourations where scanned by a high density scanner to create a .JPEG file. The ImageJ software connected values to the different colours and provided a linear scale, the Standard. Calibration of the materials Testing Machine The analogue display on the MTM showed the applied amount of force. When the lever goes up or down the number displayed changes. For this reason the machine had to be calibrated to zero after placement of every limb. The load was set to zero when after correct placement of the boll into the socket the hoof was horizontally on the hoof plate. During loading the hoofs were observed for displacement. Before the actual loading and filming of the process, the limb was subjected to a resting ground reaction force (GRF). Because we unified the body weight of the horses to 500 kg and 30% of this body weight will be carried on one front limb, the resting GRF was 1,5 kN. The MTM is connected to a MAC computer and the MAC version of the Chart 7 program. This program will show two graphics; one of the load applied to the leg and the other the transposition of the lever. To calibrate the graphs to the MTM we have to determine the zero (the resting GRF) and the maximum (when 10 kN is applied) load. Simultaneously the computer received video data from the camera that recorded the load procedure. The result is a detailed record of the relationship between the applied force and corresponding joint angle. The maximum speed in which the MTM could apply the load on the limbs was 0.99 mm/s and was consistent in every trail. This does not correspond with the speed of load build up and release in real gallop. Placement en calibration of the camera To determine the MCP joint angles so they can be related to the found pressure and lesions later on the trails of the MTM were recorded. This film material will be processed by a 2D/3D motion analysing system was used, called Ariel Performance Analysis System (APAS). One camera is placed 105 mm in front of the MTM, 100mm from the ground on a tripod. To make sure this camera stood every time on the exact same spot, we marked the position of the legs of the tripod on the ground. After a leg was fitted into the pressure machine, the area was calibrated when the camera was in place. The area was calibrated again after testing to make sure no displacement occurred during testing. Lesions The lesions found in the test limbs will be scored on grade of wear lines, cartilage damage, dorsal impact injury, POD and linear fissures using the following score table.[4] Results Of the six tested limbs, five produced useful information for this research. One limb broke its humerus at a load of 6.5 kN and with it the pin inserted into the humerus, probably because the pin was placed of center inside the humerus. Table 1 shows the change in joint angle of the fetlock joint and the hoof joint and the extension of the limbs. Leg1 17/5 AccnN45990 1.62kN Begin 5kN End Difference Fetlock Joint Angle (degrees) 163,37 143,38 19,99 Hoof Joint Angle (degrees) 169,6 161,46 8,14 Extension (Cm) 74,81 68,49 6,32 1.62kN Begin 7,5 kN End Difference 160,61 125,24 35,37 174,1 145,22 28,88 73,8 66,5 7,3 1.62kN Begin 10,5kN End Difference Leg2 18/5 Klaver 23 1.62kN Begin 5kN End Difference 158,05 111,04 47,01 172,71 135,5 37,21 73,58 61,45 12,13 Fetlock Joint Angle 148,92 126,05 22,87 Hoof Joint Angle 169,88 153,02 16,86 Extension 69,48 64,1 5,38 1.62kN Begin 7,5 kN End Difference 149,98 110,46 39,52 169,62 139,98 29,64 69,43 60,59 8,84 1.62kN Begin 10,5kN End Difference Leg4 24/5 45943 1.62kN Begin 5kN End Difference 151,74 104,35 47,39 172,98 133,25 39,73 67,8 57,5 10,3 Fetlock Joint Angle 155,68 135,17 20,51 Hoof Joint Angle 192,16 172,71 19,45 Extension 73,92 68,78 5,14 152,93 116,69 36,24 190,65 152,72 37,93 73,72 62,35 11,37 1.62kN Begin 7,5 kN End Difference 1.62kN Begin 10,5kN End Difference Begin End Difference 155,64 102,99 52,65 Fetlock Joint Angle 154,23 133,32 20,91 189,32 136,6 52,72 Hoof Joint Angle 185,31 174,01 11,3 73,7 61,38 12,32 Extension 73,86 68,75 5,11 1.62kN 7,5 kN Begin End Difference 154,98 117,53 37,45 185,89 156,13 29,76 73,91 65,16 8,75 1.62kN 10,5kN Begin End Difference Begin End Difference 155,01 107,19 47,82 Fetlock Joint Angle 154 132,99 21,01 186,61 145,27 41,34 Hoof Joint Angle 181,2 170,4 10,8 73,85 61,5 12,35 Extension 73,25 68,25 5 1.62kN 7,5 kN Begin End Difference 153,91 117,04 36,87 180,8 149,24 31,56 73,65 65,13 8,52 1.62kN 10,5kN Begin End Difference 154,75 106,54 48,21 180,45 136,78 43,67 73,9 60,94 12,96 Leg5 1.62kN 5kN Leg6 1.62kN 5kN Table 1: Maximum joint angle and extension at different loads in stance phase. The hoof joint angle was measured also to make sure there where no great deviations that could compromise the results. The measurements show that the smallest MCP joint angle can be found at the highest load, when the joint is most bend. This is when the joint is most compressed under the weight of the horse. The pressure films showed that the pressure inside of the joint shifted dorsally when the load increased. As well as the pressure medially and laterally in the center of the sagittal groove. It stayed on the same spot and did not move dorsally. The joint angle decreased as the load increased, so the smallest angle occurred at a load of 10,5 kN what is the load op gallop.[9][4] Lesions found in these limbs where graded according scoring tables.[4] Only Limb 2, 5 and 6 had gradable lesions. The other two limbs had no visible lesions. Limb 2 Feature POD Score 2 Wearlines in cartilage Cartilage loss, associated with transverse ridge Linear fissures Marginal remodeling Dorsal impact injury 1 1 Description Discoloration of the subchondral bone with mild to moderate disruption of the overlying cartilage. Partial thickness wearline in cartilage Partial thickness and cartilage loss 0 0 0 No evidence No evidence No evidence Feature POD Score 1 Wearlines in cartilage Cartilage loss, associated with transverse ridge Linear fissures Marginal remodeling Dorsal impact injury 1 1 Description Discoloration of the subchondral bone only, no disruption of the overlying cartilage. Partial thickness wearline in cartilage Partial thickness and cartilage loss 0 0 0 No evidence No evidence No evidence Feature POD Score 1 Wearlines in cartilage Cartilage loss, associated with transverse ridge 1 1 Description Discoloration of the subchondral bone only, no disruption of the overlying cartilage. Partial thickness wearline in cartilage Partial thickness and cartilage loss Limb 5 Limb 6 Linear fissures Marginal remodeling Dorsal impact injury 0 0 0 No evidence No evidence No evidence Pressure films Figure 2 shows the coloration of the pressure films inserted in the joints from limb 2 and 5. Unfortunally the films from the other joints where compromised during testing, but these looked the same as the films below. Limb 2 Limb 5 Conclusion The highest pressure found inside the metacarpalphalangeal joint was when the joint angle was small. The hypothesis was that if the load is distributed equally on a surface, on every site the pressure is the same. But this is not the case in the MCP joint. With the increase of the load applied to the limbs, the pressure inside the MCP joint shifted more dorsally. The pressure lateral and medial of the sagittal ridge increased when the load did. The load was applied on the same position. Because the pressure builds op on these certain points, just a small surface of the joint has too endure al the pressure in the galloping horse. Most of the lesions are seen on the dorsal side of the joint surface of the metacarpal bone and on both sides of the sagittal ridge. The article of Barr et al 2009 concluded that the there was a significant linear relationship between grade of POD and grades of wear lines, cartilage ulceration and dorsal impact injuries. Also there was a significant relationship between grade of POD and grade of linear fissures, but this was not linear. Most of the lesions are centred 5–8 mm proximal to the transverse ridge and may be located 3–15 mm from the sagittal ridge on either the medial or lateral condylar surfaces.[3] Discussion There was a lot of preparation done before finally the testing started. The equipment had to be installed and collected from a lot of different places. We had a few computer problems and some of the needed equipment was not available. The Material Testing Machine is an analog machine. To get this calibrated whit the computer was very difficult. The wiring was old and figuring out why the machine worked one day and not the next Took a long time. But in the end it started working, would be calibrated to the computer and finally the measurements could start. The Algrometer needed to make a standard to interpret the pressure films did not function properly. The surface of either the stamp or the mal was not horizontal enough to get a trustable standard. Fortunally the Fuji could send a standard made by them for this type of pressure film. Joint pressures were measured using pressure-sensitive film. It is necessary to keep in mind that this technique does not represent the static position in which the limb is after applying the maximum load. It is an image of the entire process. The film exits of small spheres of paint which break under a certain amount of pressure. On some location the highest pressure is during the loading procedure and not at the end. The highest pressure shifts from the central area to the dorsal margin of the articulating surface. Only the dorsal margin the maximally applied load corresponds with the most extended position. So the film technique provides information about the maximal load a certain site is subjected to during one loading cycle. Because of the intensity of the red coloration it is visible that the most pressure is applied at the dorsal margin and next to the sagittal ridge. The inserting of the film probably compromises the tissue. The extensor tendons have to be cut in order to get the film in. Synovial fluid is spilled because the joint capsule is opened. Because of the foreign object placed in the joint there is a thickness inside it which is not normal. We tested of this procedure had effect on the extension of the limb. So we put the intact limb in the pressure machine and applied the 10,5 kN. After cutting the extensors the applied the load again and there was no difference in the extension of the limb. The other two compromises we could not test is this has a big impact on the movement of the joint, but it is not hard to imaging that is will alter the movements and weight distribution inside the joint. There where rules for how the freeze and thaw the limbs. Collected limbs where put in the freezer within 24 hours and before testing a limb it had to be thawed at room temperature for 24 hours. Twice after we thawed a limb, the machine or computer did not work so we had to freeze the limbs again and thaw them another day. There is no way to be sure that this did not compromise the tissues of the limb. Because of the length of two limbs (2 and 4) it was necessary to cut more of the humerus than intended. The deltoid tuberosity was not always intact because of this. This probably compromised some tendon and muscle insertion areas. The amount of synovial fluid differs in joints. Because of this it was really difficult in a few joints (1 and 6) to insert the pressure film. There was a lot more manipulation necessary then with the other limbs. The film was not inserted as far as normal in these limbs. But the results of these limbs where surprisingly good to use. To attach the markers on the outside of the limbs glue was used. This compromised the limbs much less then screws as used in the research of Van der Wouden et al, 2007. The pin that was inserted into the humerus and connected with the socket of the MTM broke twice. The reason for this was that the angle the pin made with the top of the MTM was too sharp. So the load was applied to the limb in an angle. The pin could not handle this and snapped just above the limb and in one case the humerus broke also. It is imaginable that this gave a burst of force to the limb, which may have compromised the tissues. References 1. Perkins NR, Reid SW and Morris RS. Risk factors for musculoskeletal injuries of the lower limbs in Thoroughbred racehorses in New Zealand. N.Z.Vet.J. 2005; 53: 171-183 2. Konig, H.E., Liebich, H.G. Veterinary Anatomy for Domestic Animals. 2007; 3 3. Pool R.R., McIlwraith C.W., Trotter G.W. Pathologic Manifestations of joint disease in the athletic horse. Joint Disease in the Horse 1996; : 87-104 4. Barr ED, Pinchbeck GL, Clegg PD, Boyde A and Riggs CM. Post mortem evaluation of palmar osteochondral disease (traumatic osteochondrosis) of the metacarpo/metatarsophalangeal joint in Thoroughbred racehorses. Equine Vet.J. 2009; 41: 366-371 5. Butcher MT and Ashley-Ross MA. Fetlock joint kinematics differ with age in thoroughbred racehorses. J.Biomech. 2002; 35: 563-571 6. Rooney JR. Distal condylar fractures of the cannon bone in the horse. Mod.Vet.Pract. 1974; 55: 113-114 7. Riggs CM. Aetiopathogenesis of parasagittal fractures of the distal condyles of the third metacarpal and third metatarsal bones--review of the literature. Equine Vet.J. 1999; 31: 116-120 8. Back W, Schamhardt HC, Savelberg HH, van den Bogert AJ, Bruin G, Hartman W and Barneveld A. How the horse moves: 1. Significance of graphical representations of equine forelimb kinematics. Equine Vet.J. 1995; 27: 31-38 9. BRAMA PAJ, KARSSENBERG D, BARNEVELD A and van WEEREN PR. Contact areas and pressure distribution on the proximal articular surface of the proximal phalanx under sagittal plane loading. Equine Vet.J. 2001; 33: 26-32 10. Brommer H, van Weeren PR, Brama PA and Barneveld A. Quantification and age-related distribution of articular cartilage degeneration in the equine fetlock joint. Equine Vet.J. 2003; 35: 697-701 11. Colahan P, Piotrowski G and Poulos P. Kinematic analysis of the instant centers of rotation of the equine metacarpophalangeal joint. Am.J.Vet.Res. 1988; 49: 1560-1565 12. Harrison SM, Whitton RC, Kawcak CE, Stover SM and Pandy MG. Relationship between muscle forces, joint loading and utilization of elastic strain energy in equine locomotion. J.Exp.Biol. 2010; 213: 3998-4009 13. Lillich JD. Subchondral injury of the distal third metacarpal bone. Equine Veterinary Education 2007; 19: 349-350 14. McGuigan MP and Wilson AM. The effect of gait and digital flexor muscle activation on limb compliance in the forelimb of the horse Equus caballus. J.Exp.Biol. 2003; 206: 1325-1336 15. Brown NA, Pandy MG, Kawcak CE and McIlwraith CW. Force- and moment-generating capacities of muscles in the distal forelimb of the horse. J.Anat. 2003; 203: 101-113 16. Witte TH, Hirst CV and Wilson AM. Effect of speed on stride parameters in racehorses at gallop in field conditions. J.Exp.Biol. 2006; 209: 4389-4397 17. Den Hartog SM, Back W, Brommer H and van Weeren PR. In vitro evaluation of metacarpophalangeal joint loading during simulated walk. Equine Vet.J. 2009; 41: 214-217 18. L.K. Kappers. Analyzing the nature of the relationship between load and joint movement of the fetlock joint in thoroughbred racehorses. 2007;