CLASS VI Rev 1.4

advertisement

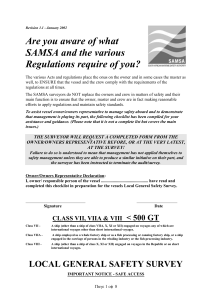

Revision 1.4 - January 2002 Are you aware of what SAMSA and the various Regulations require of you? The various Acts and regulations place the onus on the owner and in some cases the master as well, to ENSURE that the vessel and the crew comply with the requirements of the regulations at all times. The SAMSA surveyors do NOT replace the owners and crew in matters of safety and their main function is to ensure that the owner, master and crew are in fact making reasonable efforts to apply regulations and maintain safety standards. To assist vessel owner/owners representative to manage safety aboard and to demonstrate that management is playing its part, the following checklist has been compiled for your assistance and guidance. (Please note that it is not a complete list but covers the main issues.) THE SURVEYOR WILL REQUEST A COMPLETED FORM FROM THE OWNER/OWNERS REPRESENTATIVE BEFORE, OR AT THE VERY LATEST, AT THE SURVEY! Failure to do so is understood to mean that management has not applied themselves to safety management unless they are able to produce a similar initiative on their part, and the surveyor has been instructed to terminate the audit/survey. Owner/Owners Representative Declaration: I, owner/ responsible person of the vessel ............................................ have read and completed this checklist in preparation for the vessels Local General Safety Survey. Signature Date PASSENGER VESSELS - CLASS VI A passenger ship which operates at a port or is engaged on voyages to sea in fine weather with not more than 250 persons on board, in the course of which voyages the ship is at no time more than 15 miles from the point of departure nor more than 5 miles from land. LOCAL GENERAL SAFETY SURVEY IMPORTANT NOTICE - SAFE ACCESS 19 OWNERS/ OPERATORS ARE ADVISED THAT SAMSA REGARDS THE NON-PROVISION OF SAFE ACCESS TO VESSELS IN A SERIOUS LIGHT. THIS REQUIREMENT IS FOR ALL PERSONS REQUIRING ACCESS TO VESSELS (NOT JUST SURVEYORS).SAMSA SURVEYORS WILL ISSUE A “PROHIBITION ORDER”, REQUIRING THAT ALL WORK ON BOARD BE HALTED UNTIL ACCESS IS PROVIDED TO THE SATISFACTION OF THE SURVEYOR, IF THE NON-PROVISION OF A SAFE ACCESS IS NOTED AT ANY TIME. 1. DOCUMENTATION CHECK ITEM CERTIFICATE OF REGISTRY NOTES Check that the information on the certificate is correct (Not applicable to vessels under 25 GT). (MSA Sect 13 & 15) PREVIOUS LGSC & MANNING CERT’s (MSA Sect 73 & 194) LOADLINE CERTIFICATE The surveyor may want to sight the certificates of competency, so have them aboard. The vessel’s current LGSC (original copy) must be prominently displayed on board. (MSA Sect 204 & 207) This is required for all vessels of over 14 metres registered length. A Load Line Exemption Certificate may be issued in lieu of a Load Line Certificate. I.O.P.P CERTIFICATE AND ASSOCIATED DOCUMENTATION Vessels of over 400 Gross Register Tons (GT) require an International Oil Pollution Prevention Certificate, an Oil Record Book and SAMSA approved Shipboard Oil Pollution Emergency Plan (S.O.P.E.P). (MARPOL Annex 1, Reg 4, 20 & 26) HULL CERTIFICATE A valid “DRY DOCKING CERTIFICATE” must be on board. (Const Reg 193) RADIO CERTIFICATE (MSA Reg 190) STABILITY BOOK (MSA Sect 226 & S of N Reg 7) COMPASS DEVIATION CARD/BOOK (MSA Sect 228 & S of N Reg 13 & 14) NAUTICAL PUBLICATIONS (S of N Reg 15) LIFE RAFTS (LSA Reg 25) RESCUE BOAT (LSA Reg 31A, Annex 24) FIRE FIGHTING APPLIANCES (LSA Reg 118) These are carried out by I.C.A.S.A. on behalf of SAMSA. Note that the Local General Safety Certificate may not be issued until I.C.A.S.A has reported that the condition of the installed radio equipment is satisfactory. A SAMSA approved stability book must be on board. (Any special operating instructions must be posted in the wheelhouse and in the engine room, if appropriate). The validity of a deviation card is one year. A compass deviation book may be maintained in lieu of having the compass swung annually by a qualified compass adjuster. The charts are to be corrected and up to date for the area of operation. Valid tide tables and a “List of Lights and Radio signals” for the area of operation must be on board. The annual inspection/service certificate needs to be on board and may be sighted by the surveyor. The annual inspection/safety certificate needs to be on board and may be sighted by the surveyor. The surveyor may require that the launching and recovery of the rescue boat be demonstrated. The annual inspection/service certificate needs to be on board and may be sighted by the surveyor. Servicing of appliances must be carried out by a SAMSA approved “DOTFAS” station. 29 GAS CERTIFICATE (Const Reg 159) MEDICAL & MEDICAL LOCKER (MSA Sect 101, 167 & 168) AIR RECEIVER(S) (Const Reg 179) ELECTRICAL (Const Reg 180) SHIP MANEUVERING DATA (M-Notice 18 of 1991) ARTICLES OF AGREEMENT If a gas stove is fitted, an annual service certificate must be on board and may be sighted by the surveyor. The surveyor may want to sight each crew members medical certificate. A current certificate of inspection (validity = 1 year) from a Doctor or Pharmacist to be on board as well as the Ship Captains Medical Book If the Main Engines are air started, air receiver pressure test and relief valve service records must be held. Air receivers must be hydraulically pressure tested (1.5 x WP) and safety valves must be overhauled every 4 years. The surveyor may require that relief valve(s) operation be proven at the survey (1.1 x WP). Certification of any electrical testing carried out must be on board. An insulation test is to be carried out every 4 years. The resistance between all insulated circuits and earth may not be less than 100 000 ohms. For vessels over 100 GT. Information on the vessel speed at Slow, Half and Full ahead and time elapsed and distance traveled to stop in the water when going from full ahead to full astern (“crash-stop”). Required on vessels of over 100 GT To be correctly filled in. (MSA Sect 102) OFFICIAL LOG BOOK (MSA Sect 182) OCCUPATIONAL SAFETY (MOS Reg 3, 10) Required on vessels over 100 GT. Must have been correctly filled in with regard to occurrences on board (See sect 133 & 183 of the MSA). - A copy of the Maritime Occupational Safety Regulations, 1994 must be on board. - One of the ships officers must be appointed (in writing!) as the safety officer. - A file or log book must be maintained containing recordings of safety meetings, checks of safety equipment and repairs or servicing of safety equipment. - A copy of the publication “Safe Working Practices for Merchant Seamen published by Her Majesty’s Stationary Office (UK) must be on board. 2. DISTRESS SIGNALS CHECK ITEM FLARES (LSA Reg 46) NOTES - 12 x Parachute distress flares. - 6 x Daylight smoke flares (4 minute type). - All flares are to be stored in a clearly labeled watertight container. - If the vessel is restricted to port operations then only 6 x hand-held flares and 2 x Daylight smoke flares are required. FLAGS - N&C (I am in distress and require immediate assistance). LIFE SAVING SIGNALS CARD - To be kept in waterproof container with the distress signals. - If >100 GT (both ship and portable battery power source required). (LSA Reg 46) SIGNALING LAMP (MSA Sect 229, S of N Reg 17) 39 3. NAVIGATION CHECK ITEM NAVIGATION LIGHTS (Coll Regs Rule 23, 25, 27 & 30) SOUND (Coll Regs Rule 33) SHAPES (Coll Regs Rule 25, 27 & 30) DIRECTION (S of N Reg 13 & 14) NOTES - Power driven vessels < 12m - All round white and side lights. > 12m - Masthead light forward (2nd masthead light aft if > 50m), sidelights, stern light, “Not-Under-Command” lights (R-R) and an anchor light. Vessels >50m require a 2nd masthead light. - Sailing vessels Sidelights and stern-light (if < 20m these can be combined at or near the top of the mast where they can clearly be seen). 2 all-round lights may be fitted at or near the top of the mast (Top-Red, bottom-Green) but not in conjunction with a combined light. - “Not-Under-Command” lights (R-R) and anchor light(s). - NUC and anchor oil lamps are to be provided unless the vessel has two sources of power available (Battery + Generator set). - < 12m - An efficient means of making a sound signal is required. - > 12m - An efficient whistle and bell and is required. Vessels over 100m also require a “gong”. - 3 x black spheres able to be rigged to show vessel “Not Under Command”, “At anchor” or “Aground”. - 1 x conical shape (sailing vessels only indicating under sail and power). - 1 x magnetic steering compass. - A compass deviation book should be maintained by the master. If this book is not maintained to the satisfaction of the surveyor or if the compass deviation is regarded as excessive, the compass must be swung by a qualified compass adjuster. DEPTH - SAMSA recommends that an echo sounder be fitted. 3. LIFE-SAVING EQUIPMENT CHECK ITEM LIFE RAFTS (LSA Reg 11 & Guidance 2000/1) NOTES - Sufficient SAMSA-approved life-rafts to accommodate all persons on board ie 100%. - Life rafts must be of the “fully-enclosed” type ie. Not the “openreversible” type. SAMSA will only consider allowing the use of open-reversible life rafts for specific restricted operations. Prior written consent from SAMSA must therefore be obtained. - SAMSA recommends that liferafts are fitted with hydrostatic 49 RESCUE BOAT (LSA Reg 11, 31A & Annex 24) LIFE JACKETS (LSA Reg 11) LINE THROWING APPLIANCE release mechanisms. Life rafts must be stowed in accessible position(s), in the correct manner, so that they can be easily transferred to the water. - Required on all vessels > 20 m in length. - To be stowed in a cradle and be able to be launched and recovered on one side of the vessel with a full complement of persons and equipment. - To be SAMSA approved and carry required safety equipment. - To be maintained in a state of readiness for immediate use. - Sufficient life jackets for all passengers and crew are required (Adults - > 32 kg, Children - < 32 kg. - Life jackets must be SOLAS type; SABS and SAMSA approved, fitted with a SAMSA approved light. (Vessels operating within the confines of a harbor may use WORKING type life-jackets which must be fit with approved lights if the vessel operates at night). - To be fitted with a plastic whistle and reflective tape - The vessel’s name/number is to be marked on the lifejackets. - The life jackets are to be stored in a dry, accessible place. - A safety exemption from this requirement may be issued for vessels less than 100GT. (LSA Reg 11) LIFE BUOYS (LSA Reg 11 & 29) - Vessels < 21.3m = Minimum of 3 life buoys Vessels > 21.3m but < 45.7m = Minimum of 4 life buoys Vessels > 45m = Minimum of 8 life buoys - Half the number of life buoys are to be fitted with self-igniting lights (minimum of 2) - One life-buoy must be fitted with a 15 minute M.O.B. smoke marker (An exemption may be issued if an approved Dan-buoy is carried). - At least 1 life-buoy per side of the vessel is to be fitted with a 27m line. 5. FIRE FIGHTING EQUIPMENT CHECK ITEM NOTES ON DECK / ACCOMMODATION - Sufficient hydrants in number so that a single jet of water can reach any part of the vessel using only one length of hose. - A fire hose and spray/jet nozzle must be provided at each hydrant. - The maximum allowable hose length is 18.3 m. - A minimum of 2 suitable portable fire extinguishers must be provided per passenger/crew space. (LSA Reg 66 & 67) IN GALLEY (LSA Reg 67) IN ENGINE ROOM (LSA Reg 69) (Const Reg 68, 69, 103 & - SAMSA strongly recommends that a fire blanket be provided. - A CO2/Dry Powder portable extinguisher must be located at or near the entrance. - A minimum of 1 fire hydrant with hose and spray jet nozzle must be provided which can access the entire engine room (If the engine room 59 Instructions to Personnel No.15) is a manned engine room). - A fixed fire smothering (CO2 or other gas) system is required. - 1 x foam portable fire extinguisher per 375 kW installed power is required subject to a minimum of 2 and maximum of 6 extinguishers. - 1 x power driven fire pump is required. - Engine rooms are required to be “Class A” fire proofed which is essentially only achievable if the engine room is of steel construction. GRP and wooden vessels are therefore subject to the following additional requirements: - Bulkheads and deck-heads of engine rooms or compartments are to be lined with a non-combustible material or painted with a fire retardant paint. Self extinguishing laminates may also be used in the construction of the vessel. The insulating method must be submitted to SAMSA for prior approval. - Smoke/heat detectors must be fitted in each compartment. Note: Engine room configurations differ. SAMSA may therefore exempt vessels from certain safety requirements or require that additional safety equipment be fitted based on the vessels outfit. EMERGENCY FIRE PUMP (LSA Reg 70) - 1 x power or manually driven emergency fire pump is required which is to be located outside the engine room. 6. ENGINE ROOM REQUIREMENTS CHECK ITEM MAIN ENGINE (Const Regs 73 & 78) BILGE PUMPING ARRANGEMENTS (Const Reg 28, 31, 32, 33, 34, 35 & 36) NOTES The Main Engine must be able to be brought into operation when initially no power is available to the ship. - If electric start; a minimum of 1 x charging unit other than the M/E is required. It is also acceptable if the vessel has twin engines both fitted with charging units, both being capable of charging both sets of batteries. - If air start; a minimum of 1 x air receiver and 1 x compressor is required. Drains must be fitted for the drainage of condensate. - Required Pumps Boat Length Minimum number of pumps < 15.2m 1 x Main Engine driven pump. 15.2 - 21.3m 1 x Main Engine driven pump plus 1 x hand pump per watertight compartment. 21.3 - 76.2m 1x Main Engine driven pump, 1 x independent power pump and 1 x hand pump per watertight compartment. Hand operated pumps must be operable from above the main deck. The Main Engine driven pump may be replaced by an independent power pump. The hand pump(s) may be replaced by an independent pump. Bilge arrangements are to be provided for the draining of all watertight compartments. - Pipe configurations Non-return or L-cocks are to be fitted in the bilge suction lines to prevent flooding from the sea into the vessel. Non-return valves or pipe configurations must also ensure that it is not possible for water to flood from one watertight compartment to another. - Bilge alarm SAMSA strongly recommends that Audible bilge alarms for machinery spaces, which are not continuously manned, be provided 69 in the wheelhouse and engine room. FUEL TANKS (Const Reg 38, 81, 83) (LSA Reg 115) STEERING GEAR (Const Reg 85) EMERGENCY ESCAPE - Means must be provided to ascertain the tank level and prevent overpressurization. - Sounding pipes, for tanks forming part of the hull structure, in the e/r (And other spaces below the main deck) must have self-closing cocks. - Vent pipes are to be fitted with anti-flashback gauze. max = 0.5 mm of non-corrosive material. - Shut-off cocks are to be provided at all tank outlets which can be closed locally and from a remote position (not required if suction line is not gravity fed). - Ventilation of fuel spaces is to be adequate. - An efficient steering and emergency steering arrangement, which can be rapidly brought into action, is required. By-pass arrangements are to be fitted on hydraulic steering systems to prevent hydraulic locks when the emergency steering arrangement is brought into operation. - Adequate communication between the wheelhouse and steering flat must be provided. - A clearly marked, unobstructed engine room emergency escape is required if the engine room is a manned engine room. (Const Reg 90) EXHAUST LAGGING (Const Reg 79) ROTATING PARTS (Const Reg 155) (MOS Reg 18) VENTILATION (LSA Reg 115) PUMP SHUT-OFFS (LSA Reg 115) - Exhaust pipes and silencers of internal combustion engines are to be efficiently cooled, lagged or installed in such a manner that they do not create a fire hazard (Lagging, if used, must be impervious to oil or coated so that it is impervious to oil). - Protective guards are to be provided for all rotating shafts and drive belts which could result in the injury to crew under normal operating conditions. - A minimum of 2 ventilators must be provided for manned engine rooms. - Efficient closing arrangements (flaps or plugs) must be provided for ventilators. - Remote (Outside engine room) stopping arrangements must be provided for any inlet/exhaust fans fitted. - Remote (Outside engine room) stopping arrangements must be provided for all fuel transfer pumps and purifiers, if fitted 7. ANCHORS CHECK ITEM NOTES ANCHORS - Vessel’s are to be fitted with an anchor with chain which can rapidly be deployed. In general a spare anchor must also be carried unless a SAMSA surveyor is satisfied that, due to the size and intended service of the vessel, such spare anchor is not required. (An exemption can be applied for) - A windlass is required if the anchor weight is > 70 kg. - The surveyor may require that windlass operation be demonstrated. (Const Reg 88 & 168) 79 8. VENTILATION CHECK ITEM VENTILATION (Const Reg 165) NOTES - Adequate ventilation is to be provided to all spaces. - Sleeping spaces must be provided with inlet and exhaust ventilators. - Air inlets and exhausts must be close-able from an external position. 9. ACCOMMODATION AND GALLEY CHECK ITEM NOTES EMERGENCY ESCAPES (Const Reg 90) - If more than 10 people are accommodated in a space, at least one emergency escape must be provided. TOILETS - The vessel should be provided with enough toilets for the mode of operation. At least one toilet is required. ADJOINING E/R - Accommodation adjoining machinery spaces is to be fitted to prevent fumes from entering the compartment. (Const Reg 103) GARBAGE (MARPOL Annex V) GALLEY STOVES (Const Reg 45, 82 & 159) - Facilities must be provided for the retention of all plastics on board. - Fuel/power sources must be located outside the galley. - Remote isolating valves/switches must be fitted to isolate the fuel/power source. - If a gas stove is fitted; means must be provided to shut off the gas supply in the event of the flame being extinguished under any circumstances. 10. PROTECTION ON DECK BULWARKS AND RAILINGS (Const Reg 91) - Bulwarks or railings must be provided on all exposed decks to which persons have access. - The construction of bulwarks or railings must be such to prevent persons from falling over or through openings. - Particular attention must be paid to ensuring that persons are not able to sit on the bow with their legs dangling over the side. 11. ELECTRICAL EMERGENCY POWER (Const Reg 40) GENERAL (Const Reg 45) Emergency power must be provided to ensure that services essential for the safety of the ship and persons on board can be maintained in an emergency (eg. Lighting, navigation lights, bilge and fire pumps). - Electrical cabling must be of the flame retardant type. - Electrical cabling must be adequately supported and protected. - Light fittings must be located in such a way that they present no 89 fire risk. All lights must be covered. 12. PASSENGERS Passenger Operation The whole operation should be professional and safe. As SAMSA perforce has put it’s name behind these passenger operations, a high standard will be required to be upheld. Marking Number of Passengers The maximum number of passengers any passenger vessel may carry should be clearly and conspicuously marked in cases where the Certification is not clearly displayed for the passengers to read. 13. EXTENSIONS MSA Sect 197 Please note that all submissions for extensions to a vessels Local General Safety Certificate must be submitted, in writing, to SAMSA before the validity of the certificate expires. ACT / REGULATION ACT / REGULATION MSA Merchant Shipping Act 57 of 1951 LSA Life-Saving Equipment Regulations, 1968 Const Construction Regulations, 1968 S of N Safety of Navigation Regulations, 1968 MOS Maritime Occupational Safety Regulations, 1994 Coll Merchant Shipping (Collision, etc) Regulations, 1996 99