Preventing feeding tube failure by improved material selection and

DIT PhD Project

Supervisor name & contact details:

Supervisors Profile:

Research Centre:

Research Centre website:

Name Prof Steve Jerrams

Email stephen.jerrams@dit.ie

Centre for Elastomer Research (CER)

The Centre for Elastomer Research has the unique capability of producing reliable viscoelastic data for characterising the multiaxial physical properties of elastomers. Current research interests are: Hyperelastic and

Viscoelastic Material Behaviour including

Elastomer Fatigue, Stress Softening and Stress

Relaxation; Biomedical Applications; Advanced

Foams; Swelling Phenomenon. w: www.dit.ie/cer http://www.dit.ie/researchandenterprise/ditrd centres/cer/ http://arrow.dit.ie/cer/ Supervisors Publications:

Title of the Project: Preventing feeding tube failure by improved material selection and design

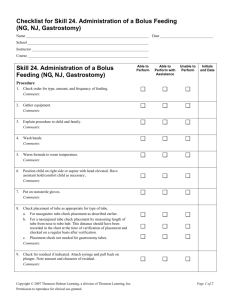

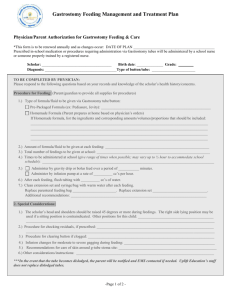

Project Summary: For gasrostomy procedures (enteral / tube feeding, figure 1), there are two primary methods; i) Percutaneous Endoscopic Gastrostomy (PEG) for long-term use, up to 2yrs retention or more, with the tube held in place against the internal stomach wall with a rubber disc and ii) Balloon Gastrostomy Tubes (BGT) for short-term use, designed for replacement every

3-6mths and held in place by inflating the balloon with water which needs changing weekly. In the former, complications arise from the disc becoming buried in the abdomen or the disc perishing and withering over time due to high stomach acidity or the influence of some medications, causing the tube to fall out. In this situation, acidity, medications or fatigue through the inflation/deflation process cause balloons to eventually burst. PEGs are usually made from polyurethane and BGTs from silicone. In PEG feeding when a tube falls out, if not replaced immediately, the tract will usually heal within 2hrs and a procedure for re-insertion requiring an overnight stay in hospital results, costing between €360-€1440 depending on the location and treatment received. Each of the materials currently used for feeding tubes have poor resistance to hydrochloric acid (HCl) and this is the main constituent in stomach acid. As the costs incurred in feeding tube failure are so prohibitive and the distress and inconvenience caused to patients is incalculable, it is timely that improved materials and designs are sought to alleviate this problem.

Hence, the Primary Aim of this research is to produce an improved gastrostomy device with superior material properties and design to that of existing devices, offering enhanced reliability and resilience without impairing functionality. To achieve this aim will require meeting the i) following Objectives. i) An analysis of the limitations of existing feeding tubes. ii) ii) A review of material selection for gastrostomy devices and an appraisal of physical and chemical properties. iii) iii) Research to determine if material improvements can be obtained from modifying the properties of existing materials. a) iv) Developing an alternative elastomeric compound. iv) v) In conjunction with iii) and employing computer simulations, a redesign of existing PEG and BGT equipment to exploit the advantages offered by an improved material. v) vi) Validating materials and design through an extensive programme of physical testing.

Figure 1 A patient who has undergone a gastrostomy procedure

This PhD programme will be carried out in collaboration with our research partners in Biomedical

Engineering in the School of Engineering at the University of Dundee and the National

Neuroscience Center of Ireland, Beaumont Hospital, Dublin.

Ciência sem Fronteiras / Science Without Borders Priority Area:

Health and Biomedical Sciences