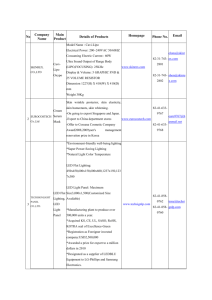

1439479299 - Rishi Laser Ltd

advertisement

CURRICULUM VITAE VIKRAM BALASAHEB GAIKWAD EmailCell No: Address- vikig9@gmail.com 9764367007 A/P- Kolapewadi, Tal- Kopergaon, Dist- A. Nagar Pin- 423602 Core Professional Strengths: 5 years experience with reputed organization in manufacturing and allied departments. Experience involves working in manufacturing department of Mechanical manufacturing companies. Working in mass type and batch type production system and culture. Exposure to use modern techniques and procedures for effective utilization of man, machine and method. Hands on experience of working on CNC Turning Center, Turn Mill Center, machining center, Hydraulic press and knowledge of programming, operating &preventive maintenance Knowledge of operating measuring equipments like Contracted, Profile projector, Surface tester & 2D height gauge . Excellent ability to work with team with good communication, meet on time by deadlines. Cutting Tool concept Design & Planning Jig & fixture Developments. Machining development at Supplier end & Good process knowledge for KANBAN system. Organization Working With: UNIDERITEND LTD NASHIK. Company Profile: Uni DERITEND Ltd. is India’s Leading &forerunner in the manufacture of Investment Castings (Lost Wax Process). As the Largest & Technically advanced, our plants have adopted to flexibility to align and meet varied demands of market and has to its credit for developing & supplying over 15,000 types of different near net shaped parts to almost every conceivable engineering application in over 225 alloys to a host of different industries. There are three manufacturing facilities in different locations offered unique proposition to customer to have practically unlimited capacities & serviceable at one contact basis. Designation& Duration: As a Junior Engineer-Production (Machine shop) from June 2014 to till date. Job profile: Individual handling of production & dispatch planning for machine shop & always seek to achieve value addition of machine shop above target. To control machining rejection & improvement in production with continuous process improvement.. Analysis & Taking corrective action of rejection. Daily Machine wise load Planning, meeting the targets. Lead & Motivate the machine shop team to achieve the set target & objective. Program Development of new component on CNC/VMC machines. Maintain all tooling, production & quality documents & controlled copy of product drawings of all items. Maintain interaction with suppliers for jigs & fixture development & machine tool development. Operating knowledge of measuring instruments like 2D Height Gauge (TRIMOS), Profile projector, Surface Tester & Contracer. Involvement in development activity in machining right from fixtures & tooling development. Lead, train & Motivate the machine shop team to achieve the set target & object. Responsible for shop floor discipline and enforcement of company rules. To arrange training program to technician & conduct training Organization Working With: Pinnacle EngplastPvt Ltd. Satpur, Nashik, (ISO/TS: 16949). Company Profile: Pinnacle EngplastPvt Ltd., established in 2012. Pinnacle EngplastPvt Ltd., is a fast growing ISO / TS – 16949 certified and are engaged in the manufacturing of Disc Brake Piston which is required for Four Wheeler. Pinnacle EngplastPvt Ltd., maintaining accuracy within 05 microns also exporting 50% of its products. The company having major customer such as Bosch Chassis Systems Pvt. Ltd., Foundation Brakes Manufacturing Ltd., Seinsa Autoferon Pvt Ltd Spain, Hema Industries Turkey, KSB Pumps Ltd., etc. Designation& Duration: As a Asst. Manager Production cum Development Engineer from Nov 2013 to May 2014. Production responsibilities: Responsible for Monthly production plan/Productivity as per Schedule and material availability. Part programming of CNC (VMC, and Slant Bed Turning Center) machines with Fanuc and Siemens control. Organizing, Leading Skill and Unskilled Manpower for Maximum Utilization. Involves achievements of monthly target by the Requirements of customers and planning. Understanding / identifying the root cause of the failure / problems. Monitor and Control- Daily Production Report Vs Planning Report. Developed new method to improve the Productivity and Quality. Handling Customer Complaints Regarding Quality Issues. Implement Corrective Action’s / Improvements / suggestions for the Better Productivity and problems solving. Co-ordination with various departments likes Material, Quality , TOOLING, PRODUCT MANAGEMENT and MAINTAINCE Development responsibilities: Identifying and qualifying new vendors, evaluating their technical commercial and capacity capabilities. Developing new vendors, assisting them in meetingPEPL technical requirements. Negotiating prices and terms of business. Working with new and existing vendors of constantly improve quality ,pricedelivery performance. Managing the supply chain for the assigned product lines, up to the Organization Working With: XAL TOOL INDIA PVT LTD PIMPRI, PUNE. Company Profile: XAL TOOL INDIA PVT LTD is one of the leading MNCs which manufacture parts for our own lightening system, located at Pimpri Industrial Area Pune and Head office at Austria. The Company does the works of casting and injuctionmould dies which is used in the assembly of lightening system. Our company has got different section as, Tool Room, Machine Shop, Design Section, Manufacturing Department, Quality department and Production Centre. Designation& Duration: As a Junior Engineer-Production (Machine shop) from Aug 2011toNov 2013. Job profile: Working as a Shift In charge on Shop Floor in Production Dept. Exposure with Preprocess & in process gauge of Mass production. Working on 5S. Manpower planning. Daily Production planning. Knowledge of selection of cutting tools. Working towards Improving Productivity and reducing Rejection Workig on precision companat ,NCcode,Generate tool path. Organization working with: AMBIKA Enterprises, Akurdi, Pune. Company Profile: The company is ISO certified & specialist in Mechanical Manufacturing ofDifferent Automobile Parts of Cast Iron, Aluminum. Designation: As CNC Operating and Programmer, July 2010 to Aug 2011 Job Profile: Solving the problems by machines, Tools and Programming. Improvement Quality and Reduce Rejection by using tools ISO 9001-2000 System like control plan. Handling of various Conventional Machine like Tuning, Milling, Drilling. Workig on precision companat ,NCcode,Generate tool path. Educational Qualification: Diploma In Mechanical Engineering in Mahatma Gandhi University Diploma in CNC Operating and Programming from Ceteb’s College of CNC Technology, Pune with First class (68.00%) HSC .(MCVC)Mechanical.from Pune Divisional Board with Higersecond class (56.50%) SSC Pune Divisional Board with Pass class (40.66%) Other Skills: Certified course MSCIT. Certified course done for CNC programming . Certified course Auto CAD. Personal Details: Date of Birth : Nationality : Sex : Marital Status : Language Known: 25/04/1990. Indian. Male. Single. Hindi, English, Marathi, Telugu. I hereby declare that the information furnished above is correct to the best of my knowledge. Place: Date: VikramBalasahebGaikwad