PPT - ISR - International Submarine Races

advertisement

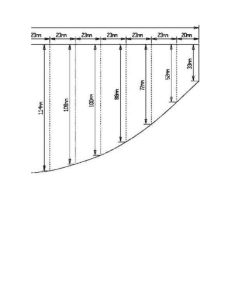

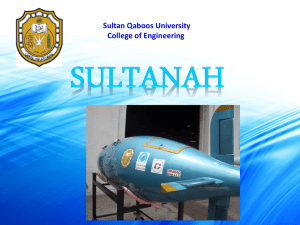

The Jesse Too The Crew Assignments Design Philosophy, Design Fabrication Hull Shannon Jorgensen Ariel Wise-Rios Propulsion, Control Tenzin Lama Adam Martino Trevor Coley Patrick Scarlett Life Support System, Safety, Testing and Training Jennifer Ruth Julia McKay Jared Arcari Journal and Budget Jade Spitale Nicole Vigorita Sarah Bell Danielle Gibbs Goals & Objectives Form a cohesive team Design and make a submarine that is balanced, buoyant, safe, and fast Certify the team by NAUI guidelines Learn to work underwater using scuba gear Experience a variety of testing situations and conditions under water Successfully race the course Have fun while learning real world skills Design Philosophy Our philosophy was to accommodate the largest individual Made to be adjustable to any height This offered any crew member to pilot the sub if they were interested And we want to win the race! Hull 11 feet long 28 inches maximum diameter Hull construction is a 3-phase process: “plug,” mold, and then the final hull Created in two halves then bonded and sealed Received help from Peter Legnos of LBI Inc., a local company that designs and builds hulls Hull halves bonded and strengthened along seams Propulsion System Components The main components that make up the submarine’s propulsion system include: The pedal Universal joint Pedal strap Right angle drive Crank Intermediate shaft Large front sprocket Propeller shaft Bicycle chain The propeller Propeller Design Constructed “the trainer” to house the propulsion system until the hull of the vessel was completed Goals: Reach a propeller speed of approximately 180 rpm that would generate the greatest thrust without being unreasonable for our pilots to pedal for the length of the course Tested two different blades, five different tests in total Performed all of our propulsion system testing at Survival Systems in Groton, Connecticut Concluded that steel propeller was more durable and a better fit than aluminum Drive Train Propeller motion driven by pilot through bike crank. Crank rotation-coupled by set of Curtis 200M 1.5:1 bevel gears through a bike chain. Primary sprocket-30 teeth Total gear ratios: 3.5:1, 3.0:1, 2.7:1 Universal joints included where drive shaft connects to the output of the gear box and where it attaches to the propeller bearing housing. Crank rate is expected to be between 60 and 70 rpm Pilot Ergonomics Prone, facilitating a full view of race course Pilots will use shoulder restraints made from a standard marching band drum frame to push against when pedaling Restraints and propulsion system is adjustable to accommodate pilots of different heights Control System Components Two horizontal fixed fins on the rear of the vessel -Helps keep the submarine level while submerged Two vertical rudders attached to the rear of the vessel -Helps move the submarine left to right Two horizontal rudders attached to the front of the vessel -Helps move the submarine up and down Modification to the hull of the submarine Drilled holes on the top of the vessel to release the air exhaled by the pilot Openings on the bottom of the hull allow for flooding and emptying the water during launch and recovery Life Support System Measured Air Consumption Primary Air Tank Placement Usage of traditional SCUBA equipment: regulator, flippers, mask, air tank Safety Color: Lipstick Red Escape: Escape hatch lined with PVC Scuba Diving Open Water Dive Testing and Training SCUBA certification Sub Trainer- submersible trainer used to experiment with drive train and propellers and give student initial pilot training Student built out of wood to measure propulsion parameters Used to determine pilots’ air consumption rates when operating the drive train at max RPM Propeller Thrust Tests •Tested the propeller shape for impact shape and pitch has on thrust Blade Type Thrust at 180 rpm (lbs) Flat, 10 deg 30 Flat, 15 deg 51.9 Foil, 10 deg 61.5 Foil, 15 deg 62 Budget Thank You! From the Miss Jesse Too Crew