State of MN

State of MN/WI

Small Boilers

Dan Chudecke

Mulcahy Co

Background

• Mulcahy Company 21 Years

– Best known for Hydronics

– Have been in the boiler business for over a decade –

– 100’s of boilers installations

• I am an actual Boiler Maker

Dan Chudecke

• Discuss modern condensing boilers

– Design

– Installation

– Inspection

– Maintenance

• McDonnell and Miller LWCO

– Recent Mishaps

– Solutions

High Efficient Boilers

• Greater portion of the overall market share

• At last count 40+ manufacturers offer some form of condensing boiler

• All are a different from each other

• All are VERY different from “Old School” boilers they are taking the place of

Comparison

• Natural draft

• Separate components for each function

• Minimal moving parts

• 83 % Max – Nat. Draft

• 85% Max – Fan Assit

• High minimum return water limitations

• Fairly High Mass

• Forced draft venting

• Combination controls that are often proprietary

• More parts and switches

• 99% efficient possible

• Lower return water limitations

• Fairly low mass

Comparison

• Full modulation usually done with full speed blower and damper

• Burners act like

‘Flamethrower’

• Simple controls

• Full Mod usually done with variable speed blower and ‘Zero

Governor’ gas valve

• Burn is more contained at a mesh or ceramic surface

• Monitor multiple points

Typical Condensing Boiler Efficienciesi.e. Laws of Physics Rule

100%

98%

96%

94%

92%

90%

88%

86%

84%

82%

60 80 100 120

Return Water, F

1/3 Input

1/2 Input

Full Input

140 160

This is what is advertised!

ENERGY CONTENT OF

NATURAL GAS

LATENT HEAT

10.2%

SENSIBLE HEAT

89.8%

Latent – Definition:

Latin for “hidden”

Comes from the difference between the H igher H eating V alue and the L ower H eating V alue of the fuel.

Heat that can be measured or felt by a change in temperature

Comes from the L ower H eating V alue of the fuel.

MORE USABLE HEAT THROUGH

CONDENSATION

Condensing boiler

Total heating value

Sensible heat Useable heat

Heating system

Condensation

Latent heat What influences the rate of condensation?

THEORETICAL PERFECT NATURAL GAS

COMBUSTION OR STOICHIOMETRIC

The CO

2

= 11.9%

The CO = 0 ppm

Excess air

0%

1 part gas

9.7 parts air by volume

Foil 11

Nov 2005

REAL WORLD NATURAL GAS COMBUSTION

WITH GOOD BURNER TECHNOLOGY

The CO

2

= 9.5 to 10%

The CO = 0 to 20 ppm

Excess air

20 to 25%

1 part gas

9.7 parts air

What can cause the amount of excess air to change after start-up?

Foil 12

Nov 2005

Lambda Pro Technology

VITODENS 200 WB2B

Lambda-Pro self calibration

Physical principal

120

110

100

90

80

70

60

50

40

30

20

10

0

0.4

Rich Combustion

(Bad)

Calibration

76 Pct

0.6

0.8

1.0

1.2

Lambda [ - ]

Lean Combustion

(Good)

Excess Air = 1.3

1.4

1.6

1.8

premix air/gas

VFD

Air/Fuel Coupling

gas valve

P

G

=

P

A

1 to 1 ratio

P

G

P

A air

Heat Exchanger Materials

• Wide range of condensing heat exchanger materials

• However all use a vent material capable of handling the acidic flue gasses.

Wall Hung “Mod Con”

• 50,000 & 400,000 btuh

• Floor mounted or wall mount

• Can be direct vented

• +92% efficient

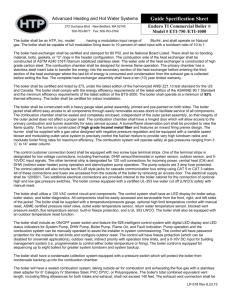

Typical Wall Hung Mod-Con

Features

• Lift off front panel

– Easy component access

– Floor or wall mount

• Quiet less than 45 db

• Light weight less than 100 lb.

• Sentry 2100T Control

• Spectacular turndown

– 6:1 (150), 8:1 (200)

The Vitodens 200-W, WB2B boilers come equipped with Lambda Pro, the industry’s first intelligent combustion management system. The boiler adjusts automatically to any gas type and quality without the need for a fuel conversion kit.

The fuel flow is checked against the optimum flame signal and the correct lambda setting is determined for the current burner cycle.

GX Features

• Stainless steel jacket

• SS screws, nuts, studs

• SS heat exchanger

• Metal fiber burner

• Fully modulating

Giannoni Heat Exchanger

Giannoni Heat Exchanger

316L Stainless Steel

Equal ????

The Giannoni 316L stainless steel oval section measures approximately 25 x 7mm with a wall thickness of 0.7mm

Viessmann corrosion resistant high grade 316Ti stainless steel.

1.5 mm wall thickness.

Not even close!!

Giannoni Heat Exchanger

condenser primary combustion chamber

GX Combustion

condensate

Composite Controls

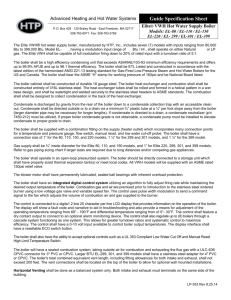

Typical Mod Con Venting Option

• Direct vent only?

• Solid core PVC, ABS,

Poly Pro, CPVC or AL

29-4C piping

– for 180° return use CPVC

• Provision for condensate removal

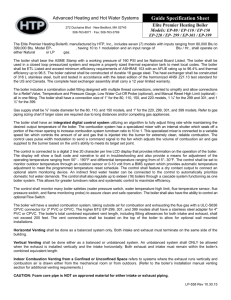

Typical Mod Con Venting

• Direct vent only,

– No inside air

– Certified for direct vent

– Potential freeze up

• 12” above snow line

• 4” lateral separation

• 18”to 36” vertical separation

• FOLLOW GUIDELINES

Inspect Burner

Clean Heat Exchanger

Annually for Propane

At least bi-annually for Natural

Gas

Other Mod Con Boilers

• Aluminum Heat

Exchanger

• Requires special glycol

• Inhibitors in typical

HVAC glycols respond badly to Aluminum

• Systems should be tagged properly

Larger Input Boilers

• Varying Heat Exchanger Materials

– Stainless Steel

– Cast Iron

– Coated Copper

– Ceramic

– Aluminum

• ALL drain off the condensate as it is formed

CONDENSING BOILER CONSTRUCTION

Condensing boiler

HS

Normal heating boiler

Hot Flue gas

HR

HR

Flue gas

HS

Condensing boiler requirements:

Counter-flow principle for flue gas and boiler water – optimal heat transfer

Parallel flow direction for flue gas and condensate – uniform flow with selfcleaning effect of heat transfer surfaces

HR

Foil 35

Nov 2005

Counter Flow

Arrangement

Other Condensing Designs?

• Primary Heat-X

• Second

Condensing Heat

Exchanger

• “2 nd Swipe” type systems often get a few more points of efficiency

Compact Designs

• Thru 6,000,000 input per device

• Generally fit thru a standard doorway.

premix air/gas

VFD

Air/Fuel Coupling

gas valve

P

G

=

P

A

1 to 1 ratio

P

G

P

A air

Start-up and Installation

• Each boiler manufacturer is different

• Many require certified start-up for warranty to be valid

• Here is a partial list of things to consider

Installation/System Design

• Minimum Water temperature

• Minimum Flow consideration

• Glycol?

• Condensate Treatment

– Boiler condensate is a low grade acid that can ruin cast iron pipes

– Running the liquid through limestone brings the pH to 7

• Sealed Combustion

– Boiler Designers don’t really know what -20F is like

– Outside Air temp can easily get below a conditioned spaces dew point

pH VALUES OF VARIOUS FLUIDS

0 1 2 3 4 5 6 7 8 9 10 11 12

0 1 2 3 4 5 6 7 8 9 10 11 12

Dilute sulfuric acid reacts with metals via a single displacement reaction as with other typical acids, producing hydrogen gas and salts (the metal sulfate). It attacks reactive metals (metals at positions above copper in the reactivity series) such as iron, aluminum, zinc, manganese, magnesium and nickel.

Condensate Neutralizers prevents acidic condensate from corroding drains and sewer systems,

Neutralized condensate is more environmentally friendly

Testing

• Blocked flue and blocked combustion air

• Gas pressure loss going into the boiler

• Gas shut off going to the burner

• Loss of VFD/Fan

• Test Manual reset boiler high limit

• LWCO

• Combustion setup at various input rates

Combustion

• Setup should be per manufacturers recommendations

• O2 readings are generally MUCH lower than what older boilers are setup for

• For example – We set our boilers up for

3-5% O2 at high fire and 5-6% at low

• Old guidelines were 4-10% -

• 8-9% will likely cause C.O. problems

Maintenance

• After the boiler has been in service for a period of time, the boiler should be rechecked (anything changed)

• An annual checkup (if not more) is usually recommended/required for warranty reasons.

• Some boilers require periodic parts replacement

• Annual testing of the glycol is recommended and often provided by the glycol supplier

Boiler Questions?

McDonnell and Miller LWCO

• Brief history of ….. Issues.

McDonnell & Miller

• Mercury Phase Out

• Overload Issues

– Current 150/157 carries the same load capability-7.4 Amps @ 120V

– The old switch was actually capable of more

• Float Sticking

– Changed bellows manufacturing process in

June of 1999 (Last known modification)

• “MD” Application