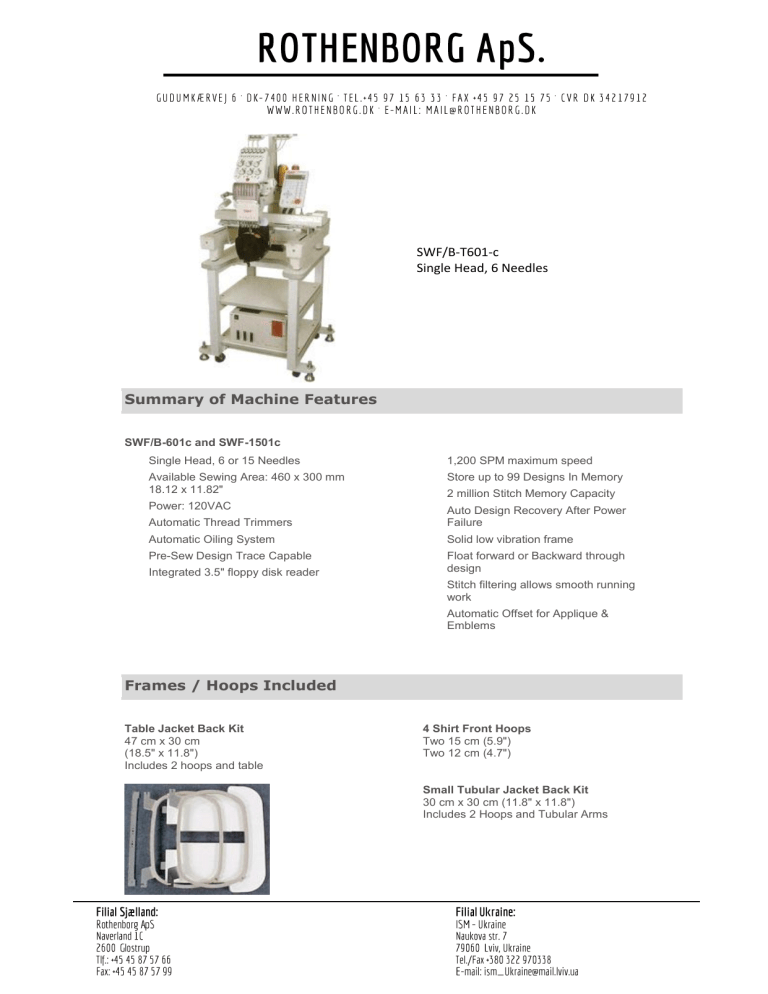

SWF/B-T601-c Single Head, 6 Needles Summary of Machine Features SWF/B-601c and SWF-1501c Single Head, 6 or 15 Needles 1,200 SPM maximum speed Available Sewing Area: 460 x 300 mm 18.12 x 11.82" Store up to 99 Designs In Memory Power: 120VAC Automatic Thread Trimmers Auto Design Recovery After Power Failure Automatic Oiling System Solid low vibration frame Pre-Sew Design Trace Capable Float forward or Backward through design Integrated 3.5" floppy disk reader 2 million Stitch Memory Capacity Stitch filtering allows smooth running work Automatic Offset for Applique & Emblems Frames / Hoops Included Table Jacket Back Kit 47 cm x 30 cm (18.5" x 11.8") Includes 2 hoops and table 4 Shirt Front Hoops Two 15 cm (5.9") Two 12 cm (4.7") Small Tubular Jacket Back Kit 30 cm x 30 cm (11.8" x 11.8") Includes 2 Hoops and Tubular Arms Machine Control Panel Memory Capacity: 2 million stitch memory capacity and 99 design memory capacity Rotate, Mirror Image Conversion: All designs can be converted into symmetry by turning 0º~359º. Scale Up/Down: Within the range of 50~200%, the machine can extend and reduce by 1% to X or Y direction. Built-in 3.5" FDD: FDD is installed in the machine, which can save 480,000 stitches / 233 designs at maximum per 2HD floppy disk so input and output for various designs are available. (Both 2DD and 2HD can be used).The machine can read and save disks with SWF format, which is compatible with different formatted designs from other company codes by automatic recognition. It is also very convenient to output data with the codes of other companies. Manual/Automatic Offset: During the embroidery work for appliqué and frame change, the frame can be returned to the previous position with only simple key operation. If you designate automatic offset position in the setting mode, it can be returned to the previous offset position after finishing embroidery work. Origin Return / Frame Offset: During the embroidery work, the frame returns to the starting point of design, and if there is any problem occurred, you can make the frame go back for the correct embroidery work. Tracing: For accurate position of embroidery, the machine traces the outline of design before starting main operation. Automatic returns to the suspension point after power failure: When unexpected power failure occurs, it can search for the exact suspension spot automatically for continuous operation to prevent from inferiority of production. Floating: The frame can process both forward and backward without stitching by units of 1, 100, 1000 and 10000 stitches or by color code. Accessories Included Operation Manual Bobbin Winder Cap Frame Manual Quick Reference Manual Tool Kit with necessary screw drivers, wrenches, etc. Parts Book Machine Grease Backup of Software on Disk Machine Oil and Oiling Bottle Machine Stand - 29" x 24 1/2" x 29" (w, d, h) Optional Starter Kit 1-Head Starter Kit: 15 Cones of Thread 1 roll (10"x110 yds) of Solvy 20 pcs. 15"x15" felt 1 box (100) of needles (#11BP) 1 metal thread nipper 1 box (144) of bobbins 1 seam ripper 1 roll (4"x250 yds) of tearaway backing 1 thread color chart 1 roll (21.75"x100 yds) cutaway backing Dakota Collectibles 100 Stock Designs Optional Accessories Large Tubular Jacket Back Kit 41.2 cm x 27 cm (16.2" x 10.6") Includes 2 hoops and tubular arms Rapid Change Cap Kit: 1 Cap Driver 1 Cap Gauge 2 wide Cap Frames Machine Size/Weight Size (w,d,h): Weight * (uncrated): 76.2cm x 76.2cm x 152.4cm 63.5kg (Rounded to nearest .5 for simplicity) * This weight does not reflect the shipping weight due to dimensional weight used by the shipping companies.