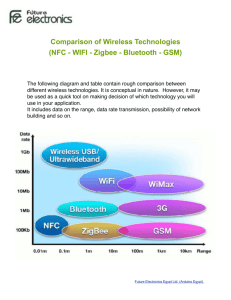

GSM AND LIGHT HARVESTING BASED AUTOMATION SYSTEM; APPLICABLE ON EVERY PLATFORM Abstract The lack of management and efficient techniques to prevent the leakage of hazardous chemicals from industries has led to introduce more coherent methods to dismantle this issue. As industries flourish across the globe, managing them becomes a menace for people. Leakage of hazardous chemicals can become a major source of affecting human lives abruptly. The Corona Virus has been a pure example of an industrial leakage that took place in Wuhan, which is an industrial based city. However, it was very unfortunate that this chemical leakage entered the food market near the industries in Wuhan which formed the deadly Corona Virus. In this project we use few modules, Arduino and sensors, which are programmed in a manner that will allow us to manually control and automatically monitor the internal factors and conditions of an industry. Arduino has been used in the past with a Bluetooth device on a small-scale, such as a security system which enables the user to manually control electrical appliances through commands, but this is can be the first time we would apply this modification on a large-scale platform without using Bluetooth. Using Bluetooth created a specific range for Arduino to work, however, in this modification we have introduced a GSM module and a light harvesting material instead of a Bluetooth module which allows us to control factors by sitting anywhere in the world. Unfortunately, we have not yet considered this idea for we believe that we have more systematic and methodical ways of maintaining industries, which of course is not true. Light harvesting is the study of materials and molecules that capture photons of solar light. This includes studies to better understand the lightharvesting properties of photosynthetic organisms or those of artificial systems that are designed and synthesized to promote photochemical reactions or produce solar fuels. The idea aims to prevent any unnecessary damage that could be done due to lack of productivity and efficiency. The components are inexpensive and the process is very simple. This system is fully automated. So once this system is installed inside an industry or an any other platform,, then it does not require any human interaction to operate.