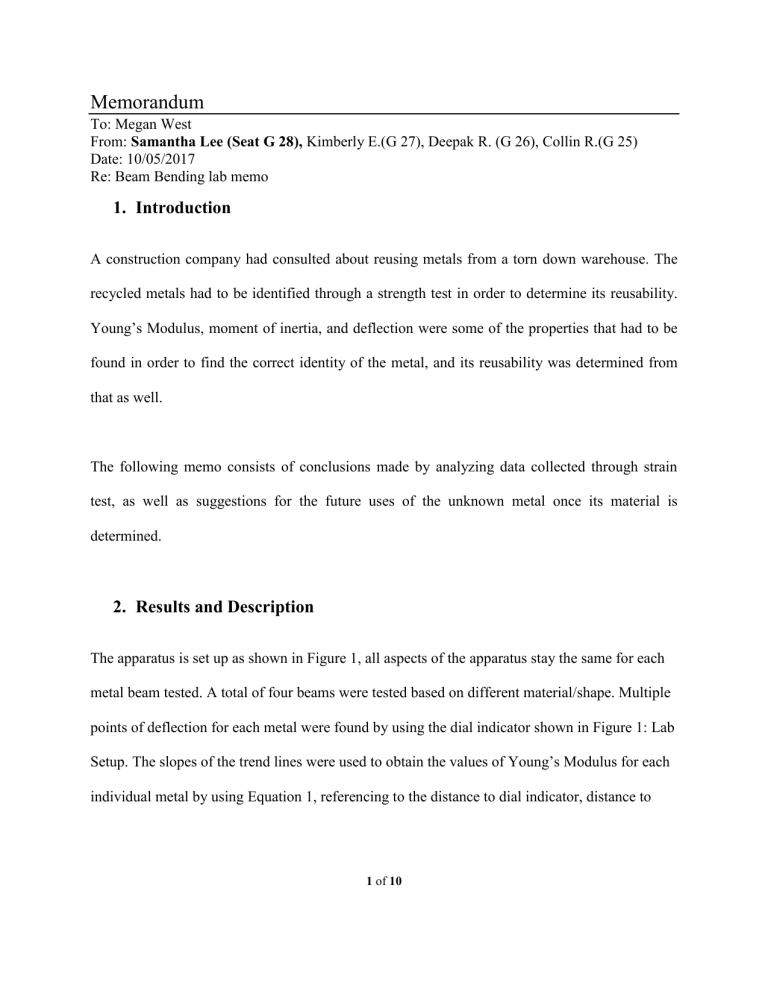

Memorandum To: Megan West From: Samantha Lee (Seat G 28), Kimberly E.(G 27), Deepak R. (G 26), Collin R.(G 25) Date: 10/05/2017 Re: Beam Bending lab memo 1. Introduction A construction company had consulted about reusing metals from a torn down warehouse. The recycled metals had to be identified through a strength test in order to determine its reusability. Young’s Modulus, moment of inertia, and deflection were some of the properties that had to be found in order to find the correct identity of the metal, and its reusability was determined from that as well. The following memo consists of conclusions made by analyzing data collected through strain test, as well as suggestions for the future uses of the unknown metal once its material is determined. 2. Results and Description The apparatus is set up as shown in Figure 1, all aspects of the apparatus stay the same for each metal beam tested. A total of four beams were tested based on different material/shape. Multiple points of deflection for each metal were found by using the dial indicator shown in Figure 1: Lab Setup. The slopes of the trend lines were used to obtain the values of Young’s Modulus for each individual metal by using Equation 1, referencing to the distance to dial indicator, distance to 1 of 10 force, and the moment of inertia. The final Young’s Modulus for the unknown metal was calculated to be 28324377.06 psi, which was identified to be steel. Figure 1. Displays the setup of the lab calculating the force vs. deflection for all four beams Deflection vs Force For all Four beams Unknown beam Absolute Deflection (in) 0.3 0.25 0.2 copper Square beam 0.15 0.1 aluminum cantilever beam 0.05 0 0.000 -0.05 0.200 0.400 0.600 0.800 1.000 1.200 Copper Rectangular Beam Force (weight) Applied to Beam (lbf Figure 2. Illustrates the deflection vs. Force for all four beams, with trend lines labeled. 2 of 10 3. Discussion Based on Figure 2, it was concluded that there’s an inverse relationship between the slope of trend line and Young’s Modulus. Aluminum had the weakest strength as it had the steepest slope, and copper square beam had the highest strength as it had the most level slope. As the slope got steeper, the value of Young’s Modulus got smaller, which correlated to high elasticity. This was also the reason why Equation 1 in the Sample Calculation Attachments included the inverse of the slope. The theoretical deflections for the first three known metals all demonstrated a positive linear relationship between the forces applied to beam vs. absolute deflection. The trend line collected for the steel (unknown) metal reflected that as well, thus the calculation for the unknown beam was supported. The importance of the shape of the material is demonstrated by Figure 2 illustrating the force vs. deflection for all four beams, the copper rectangular beam had a steeper slope than copper square beam because it has a lower Young’s Modulus value, this is because the cross section of square offers more support than a rectangle thus making it less susceptible to deflecting. Another variable that impacted the strength of beams include thickness. Based on Equation 2, the thicker the beam, the larger the calculated moment of inertia would be since the thickness was cubed, which would result in smaller calculated value of deflection, indicating a higher strength in the beam. The percent error of 4.905% could be due to random error while performing the reading of the dial indicator and rounding of significant figures. The screw securing the dial indicator at the 3 of 10 bottom of the lab stand came loose during the process of collecting data, it was caught in time and re-secured but might have an impact on the data recorded. This could have impacted the data collection by having very large readings of the dial indicator which would lead to falsely large calculations of the slopes of the trend lines and smaller calculation of the Young’s Modulus for the unknown metal, all of which would impact the final determination of the unknown metal. The data for the copper square beam were cited from Collin and Deepak due to the technical difficulty experienced with the lab apparatus. [See Reference 1] 4. Summary and Conclusions Steel was identified as the unknown material through the strain tests conducted in this experiment. Based on its high Young’s Modulus, the steel scraps from the abandoned manufacturing plants can be repurposed by melting down into squares for better support and strength, as proven by the force vs. deflection graph illustrated in Figure 2, and used to build more structures such as office buildings, bridges, and/or other projects because of its high resistance to deflection in comparison to other three metal beams tested. (See Figure 3.) To avoid errors in future labs, check the lab apparatus before starting to ensure all parts have been tightened properly. Multiple measurements of each metal beam should be taken in order to obtain the most precise readings. These cautions should be followed closely to ensure that the data collected are unbiased, useful and meet the needs of clients. 4 of 10 Attachment: Sample Calculations, 1. Attachment: Figures and Tables, 1. Attachment: Symbols, 1. Attachment: References, 1. 5 of 10 Sample Calculations 𝜎𝑒 = 𝜀= 𝐹 𝐴0 (1) 𝐿 − 𝐿0 𝐿0 (2) Sample Calculation for Equation 1 Moment of Inertia Equation: 𝐼 = 𝑊𝑡 3 12 𝐹∗𝑆 2 ∗(3𝐿−𝑆) Theoretical deflection: δ= 6𝐸∗𝐼 (equation 2) (equation 3) Sample Calculation for Percent Error 6 of 10 Figures and Tables Table 1. Combined Force vs. Deflection graph for all four beams Aluminum Rectangular Copper Square Copper Measured Deflection (in) Force (lbf) Measured Deflection (in) Force (lbf) Force 0 0.110231131 0.220462263 0.330693394 0.440924526 0.551155657 0.661386789 0.77161792 0.881849052 0.992080183 1.102311315 Measured 0.000 0.026 0.050 0.074 0.100 0.125 0.151 0.175 0.201 0.226 0.25 Force 0.000 0.110 0.220 0.331 0.441 0.551 0.661386789 0.77161792 0.881849052 0.992080183 1.102311315 Number of weights (50gm) Absolute Deflection (in) Force 0 0.026 0.050 0.074 0.100 0.125 0.151 0.175 0.201 0.226 0.250 Measured 0 0.110 0.220 0.331 0.441 0.551 0.661 0.772 0.882 0.992 1.102 Measured 0.000 0.014 0.028 0.042 0.055 0.070 0.084 0.098 0.113 0.128 0.141 Unknown Metal Number of Absolute Weights Deflection (50 gm) (in) Force Measured 0 0 0.110 0.008 0.220 0.018 0.331 0.026 0.441 0.036 0.551 0.045 0.661 0.054 0.772 0.058 0.882 0.072 0.992 0.081 1.102 0.090 Deflection vs Force For all Four beams Unknown beam 0.3 Absolute Deflection (in) 0.25 0.2 copper Square beam 0.15 0.1 aluminum cantilever beam 0.05 0 0.000 -0.05 0.200 0.400 0.600 0.800 1.000 1.200 Force (weight) Applied to Beam (lbf Figure 3. Combined Deflection vs Force for all four beams 7 of 10 Copper Rectangular Beam Deflection vs. Force of unknown metal beam 0.1 y = 0.0813x - 0.0005 Absolute Deflection (in) 0.09 0.08 0.07 Measured 0.06 0.05 Linear (Measured) 0.04 0.03 0.02 0.01 0 0.000 -0.01 0.200 0.400 0.600 0.800 1.000 1.200 Force (weight) Applied to Beam (lbf) Figure 4. Deflection vs. Force of Unknown Metal Beam 8 of 10 Symbols 𝜎𝑒 Engineering stress 𝐹 Force 𝐴0 Initial area 𝜀 Engineering strain 𝐿 Distance to fore S Distance to dial indicator w Width of beam t Thickness of beam E Young’s Modulus I Moment of Inertia δ Theoretical Deflection 9 of 10 References [1] Lab 03 data excel from Collin and Deepak, 2017, September 11th.. [2] Lab 03 Procedure. 2017, September 14th. https://app.box.com/embed/s/arlarr4zh31r5nl31mb9xg4dy0b10y2f?view=list&sortColum n=name&sortDirection=ASC&showItemFeedActions=true&showParentPath=true 10 of 10