Efficient application

advertisement

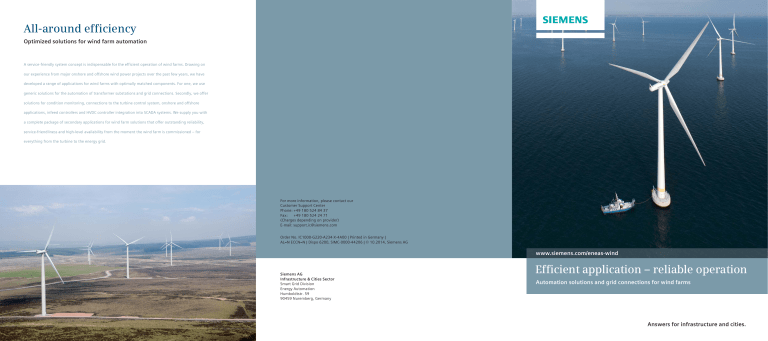

All-around efficiency Optimized solutions for wind farm automation A service-friendly system concept is indispensable for the efficient operation of wind farms. Drawing on our experience from major onshore and offshore wind power projects over the past few years, we have developed a range of applications for wind farms with optimally matched components. For one, we use generic solutions for the automation of transformer substations and grid connections. Secondly, we offer solutions for condition monitoring, connections to the turbine control system, onshore and offshore applications, infeed controllers and HVDC controller integration into SCADA systems. We supply you with a complete package of secondary applications for wind farm solutions that offer outstanding reliability, service-friendliness and high-level availability from the moment the wind farm is commissioned – for everything from the turbine to the energy grid. For more information, please contact our Customer Support Center Phone: +49 180 524 84 37 Fax: +49 180 524 24 71 (Charges depending on provider) E-mail: support.ic@siemens.com Order No. IC1000-G220-A234-X-4A00 | Printed in Germany | AL=N ECCN=N | Dispo 6200, SIMC-0000-44206 | © 10.2014, Siemens AG www.siemens.com/eneas-wind Siemens AG Infrastructure & Cities Sector Smart Grid Division Energy Automation Humboldtstr. 59 90459 Nuremberg, Germany Efficient application – reliable operation Automation solutions and grid connections for wind farms Answers for infrastructure and cities. Trouble-free connections to the grid Wind farm energy control – from the turbine to the grid Power quality should not only be ensured at the transfer point of the energy from the wind farm to the power grid. Network and wind farm operator demands in terms of infeed capacity and cos phi must also be matched to the wind farm’s potential. The infeed controller is the information hub between the wind farm and the grid. Our solution offers the possibility of controlling the turbines and using the existing capacitor banks for compensation – always in coordination with power quality information at the interconnection point. With individual wind farms or small systems, the infeed controller can be integrated into the energy control system. It can also be installed separately for infeed or interconnection points that are fed in from several wind farms. Whatever your wind farm grid connection requirements call for, we offer a highly flexible control system for energy automation that utilizes proven protection and telecontrol technology. Thereby, all of the information is gathered in the wind farm energy control system. EEG management options Power reduction in accordance with the German Renewable Energies Act (EEG) constitutes a special form of wind farm control. It limits wind farms to 0, 30 or 60 percent of their maximum power generation capacity as specified by the transmission control operator. The power that is not fed in is calculated and reimbursed. We also offer an EEG management solution that handles the planning, implementation and documentation of EEG measures. The SCADA system also enables connections to other external control centers, for example, to the grid operator or to a central control station of the system operator. It thereby acts as a control hub for all information of the various partners. In this way, it provides optimal support for the operation, fault analysis and fault correction as well as for wind farm-related maintenance tasks. • Wind farm and platform information Features • Scalable system – from single workstation to multi-server, multi-client system on small onshore wind farms as well as large offshore platforms • Wind SCADA information • User and rights management for the various user groups • Remote service connection • More than 200 communications protocols for the integration of all available data and components • Protection device data • Grid connection and power quality As such, it offers access to all essential alarms, events, trends and archive data within a homogeneous environment. Straightforward displays allow users to visualize and monitor the operation of their wind farm. The system logs every operating status, enabling subsequent review of proper operation and documentation. As such, every operating status can be analyzed and optimized. – e.g., IEC 61850, IEC 61400 protocols, dnp3, modbus, ICCP (TASE2) • Integration of protection and telecontrol technology, also wind farm and platform data into one system • Fully developed security and system update concept • Service interface for easy yet secure remote services SCADA system Wind SCADA The most important controller is the Wind Farm Management SCADA or Wind SCADA. As a special, high-performance system, it gathers all information from the wind turbines. Depending on the turbine type, it uses more than 3,000 data points for precise turbine control and monitoring. It then processes the collected data for turbine fault diagnosis and forwards them to the manufacturer’s service center. It also features a communications interface to the wind farm energy control system. Here, data such as controlling power range, availability, status and the most critical alarms are easily and reliably forwarded, as well as setpoint entries received and processed for turbine control. Connections with Wind SCADA systems from Siemens wps SCADA, Multi Level Wind SCADA (WinCC OA) and from other turbine manufacturers have already been implemented in existing projects. Platform/wind farm information In medium-sized and large-scale wind farms, a number of additional signals are provided apart from the Wind SCADA signals – for example, from parts that are connected to the central control center system. As a result, you no longer need to connect from one system to the next in order to access data from various sources and to evalu-ate them simultaneously. Instead, you are immediately provided with a comprehensive overview. Letting you benefit from fast system diagnostics and convenient troubleshooting as well as prompt repair. Remote operation and service center – everything under control Today’s wind farms are already capable of matching the power generation performance of conventional power plants. However, they are not operated in shifts around the clock by control center staff. As is typical of decentralized power generation, the systems generally operate independently, right down to the individual onshore turbine. As a result, there is an increased focus on establishing remote operation centers – a trend that control center technology from Siemens Energy Automation also supports. Thanks to the experience we’ve gathered from more than 1,600 control centers worldwide, we are well aware of remote operation and service center requirements for wind farms, and are able to assist customers with the implementation. From Web access to controllers on small systems to control centers capable of monitoring and operating several hundred of wind farms and substations via telecontrol links, solutions can be scaled to any size. The Siemens offshore service center for wind farms also utilizes this efficient base system. The applied analysis methods allow for an accurate diagnosis of the system status and provide optimal maintenance and repair support. Always with the aim of identifying threatening faults early and preventing associated expensive downtimes. Data concentrator & communication Connection to: • Grid operator • Platform / wind farm owner • Service and support provider Power quality IEC 61850 Switch MV Switch HV SIPROTEC (station automation) Grid connection SIPROTEC (turbines) Wind SCADA Energy control system Wind farm / platform signals Wind SCADA / Wind farm platform Remote access / service Remote access Benefits at a glance • A joint platform for protection systems, substation automation and distribution systems for onshore and offshore wind farms • Reduced system complexity without functionality and cyber security reduction • Lower testing and engineering costs thanks to matching engineering tools • Efficient system design for fast fault localization • Effective maintenance through optimal data utilization • Optimized system architecture and functionalities to decrease downtime and enhance reliability • Energy and platform automation engineering from Siemens with a strong project experience References A few examples of projects where our solutions are used: • Wind farms on over 20 platforms in the North and Baltic Seas • UK Round II projects • Remote wind farm monitoring (Portugal, Spain) • Control center system for OWP local operation • Control center system for HVDC transmission platform • Control center system at the Siemens Customer Support Center, Offshore