oiml bulletin - Organisation Internationale de Métrologie Légale

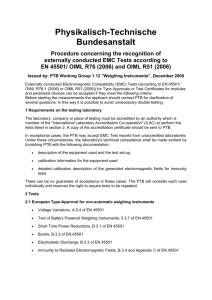

advertisement