RF CABLE

advertisement

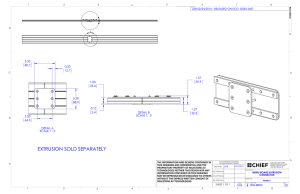

RF CABLE High Speed Extrusion of physically foamed 50 Ω RF Cable • 50 Ω RF Cable Products 1/4” – 1 5/8” • PE Materials and Additives • Physically Foaming Agents • SIEBE High Speed Line 5/8” – 2 ¼” 1. Product – 50 Ohm RF Cables When it comes to connecting the mobile communication antenna with the base station, 50Ω radio frequency cable, manufactured on SIEBE extrusion lines, are the optimum antenna cable for the job. They offer excellent return loss and extremly low attenuation due to a dielectric, that consists of highly foamed Polyethylene. Generally 50Ω radio frequency cables are constructed as follows: • Inner conductor of bare copper wire, smooth copper tube or corrugated copper tube • Dielectric of highly foamed polyethylene • Outer conductor of a corrugated copper tube with annular or spiral corrugation, depending on the flexibility required • External sheath of PE or FRNC 1. Product – 50Ω RF Cables ¼” – 2 1/4” Cable Conductor Conductor ∅ Insulation Insulation ∅ Capacitance Impedance ¼“ Copper wire 1.90 SF (SFS) PE 4.40 80 50 3/8“ Copper wire 2.60 SF (SFS) PE 6.50 80 50 ½“ Copper wire 3.55 SF (SFS) PE 9.30 80 50 5/8“ Copper wire 6.60 SF (SFS) PE 15.50 76 50 7/8“ Smooth copper tube 9.10 SF (SFS) PE 22.50 76 50 1 ¼“ Smooth copper tube 12.70 SF (SFS) PE 32.50 78 50 1 5/8“ Corrugated copper t ube 17.30 SF (SFS) PE 42.20 76 50 2 ¼“ Corrugated copper t ube 20.80 SF (SFS) PE 49.70 74.5 50 2. Materials for 50Ω RF cables Your 50Ω radio frequency cable cable needs the best insulation materials to achieve oustanding electrical performance for high-speed, error-free signal transmission. Company E Company R LDPE BP 8063 25 % LDPE Equistar NA-217-000 30 % HDPE Borealis HE1105 75 % HDPE Equistar M 5370 WC 70 % Nucleation Dow DGDA-6923 NT 0.2 % Nucleation Azodicarbonamid + Irga nox 0.3 % Foaming Carbon dioxide CO2 Foaming Carbon dioxide CO2 2. Materials for 50Ω RF cables Other suitable materials for RF cable production are: • HDPE: Borealis HE 1104 • MDPE: BP MD 8007 • HDPE: Dow HDGDA-6944 • LDPE: Dow DFDA-1253 • Nucleation: Borealis 1102 Actually SIEBE and DOW has closed a secrecy agrreement for the developing of new materials for high frequency cables. The first step of the cooperation is the developing of a new nucleation system, which will be introduced in 2003. 2. Materials for 50Ω RF cables • Comparison of Borealis Polyethylene The value is too high for RF Cable. HE1102 ME1104 HE1105 Type HDPE MDPE HDPE Density(kg/m3) 948 932 947 MFR(g/10min) 5.0 3.0 3.3 OIT(min) 40 30 30 Dielectric Constant(1Mhz) 2.4 2.30 2.33 Nucleating Agent included 5~10% HE1102 5% Polyone 207-FT-50 (5% zodicarbonamide) Max. Expansion 75% 80% 81% Main Application CATV CATV, RF RF 2. Materials for 50Ω RF cables • Comparison of HD Polyethylene Important M5370WC DGDA-6944 HE1105 Type HDPE HDPE HDPE Density(kg/m3) 953 965 947 MFR(g/10min) 7.0 8.0 3.3 OIT(min) NA 50 30 Dielectric Constant(1Mhz) 2.34 2.34 2.33 Nucleating Agent NA 0.1~0.3% DFNA0012NT/0078NT 5% Polyone 207-FT-50 (5% zodicarbonamide) Comments Narrow Molecular Weight distribution Together with DFDA-1233NT RF 2. Materials for 50Ω RF cables • Comparison of LD Polyethylene NA217-000 BP8063 DFDA-1253NT Type LDPE LDPE LDPE Density(kg/m3) 923 923 919 MFR(g/10min) 5.6 1.5 1.8 Dielectric Constant(1Mhz) 2.28 NA 2.27 Comments Medium Molecular Wieght 2. Materials for 50Ω RF cables For the inner skin, we recommend the “low loss“ LPDE: • BOREALIS LE 6006 •Low Density Compound • Density 918kg/m3 • MFR 0.3g/10min • Dielectric Constant(1MHz) 2.29 3. Physically Foaming Agents SIEBE offers today gas injection systems SGI for following gases: 1. Carbon dioxide CO2 2. Nitrogen N2 3. Argon Ar 4. Helium He On SIEBE extrusion lines for high frequency cable production today mainly CO2 is used as foaming agent. 3. Physically Foaming Agents T r e ib m itte l F orm el M o lm a s s e S ie d e p u n k t D if f u s io n L ö s lic h k e it [g /m o l] [°C ] [x * N 2] [x * N 2] [1 0 1 3 m b a r ] n -B u ta n C H 3(C H 2)3C H 3 5 8 .1 -0 .5 ca. ? 0 .1 i-P e n ta n (C H 3)2C H C H 2C H 3 7 2 .2 2 8 .0 ? ca. 1000 K o h le n d io x id CO2 4 4 .0 -7 8 .4 ca. 1 ca. 10 S tic k s to f f N2 2 8 .0 -1 9 5 .8 ( := ) 1 ( := ) 1 R 11 C F C l3 1 3 7 .4 2 3 .8 ? ? C H C l3 C F 3 1 5 2 .9 2 7 .8 ca. ? (T r ic h lo r f lu o r m e th a n ) R 123 100 W asser H 2O H e liu m He 1 8 .0 1 0 0 .0 5 - 4 .0 -2 6 9 .0 60 0 .2 5 3. Physically Foaming Agents Advantages of CO2: Higher solubility coefficient than nitrogen N2 → Higher max. foam degree → Better cell structure → Better attenuation → More stable process → Slower expansion → Higher production speeds 3. Physically Foaming Agents Price comparison CO2 to N2: Carbon dioxide CO2: € 67.00 for 25 kg Nitrogen N2: € 20.00 for 25 kg The CO2 consumption for the production of 1 5/8“ with a production speed of 8 m/min is approx. 2 kg/h. 4. Extrusion Line for 50Ω RF cable Innovation is the key to any successfull enterprise. At SIEBE, we are committed to the development of high-speed 50Ω RF cable extrusion lines and processing procedures that bring innovative solutions with highest productivity and excellent quality to your business. Our team of scientists and technicians is dedicated to technical precision, quality and reliability in every product we make. 4. Extrusion Line 5/8” – 2 1/4” The SIEBE high-speed 50 OHM RF cable extrusion 5/8“ – 2 ¼“ is basically consisting of: 2 Pay-offs for reels up to 2.500 mm flange diameter 1 Sizing / calibration unit 1 Dual disc capstan 1000 – 1200 mm 1 Pushing caterpillar 1500 – 2000 mm 1 Ultrasonic conductor cleaning station (mainly used for smooth copper tube) 1 HF conductor preheating 1 Skin extruder HSP 45-25D with crosshead and vacuum pump for tubing 1 Diameter gauge for skin diameter 1 Cooling trough with dryer for skin layer (2m length) 1 Gas injection foam extruder 125-33D GI with special extrusion gear pump and crosshead 1 Gas injection system SGI-C 1 Special RF cable calibration unit 1 Special RF telescope cooling trough (length 10 m) with one capacitance measuring tube 1 Wandexe 1 Dip cooling trough (min. 70 m for high production speed) with capacitance and special cable dryer 1 Diameter gauge 1 Pushing caterpillar (1.500 – 2000 mm) 2 Take-up up to 2.500 mm flange diameter Take-up 1 State-of-the-art electrical control and visualization system 4. Extrusion Line 5/8” – 2 1/4” Cable Conductor Conductor Insulation Insulation ∅ Production speed 5/8“ Copper wire 6.60 SF (SFS) P E 15.50 50 m/min 7/8“ Smooth copper tube 9.10 SF (SFS) P E 22.50 30 m/min 1 ¼“ Smooth copper tube 12.70 SF (SFS) P E 32.50 15 m/min 1 5/8“ Corrugated copper tub e 17.30 SF (SFS) P E 42.20 9 m/min 2 ¼“ Corrugated copper tub e 20.80 SF (SFS) P E 49.70 5 m/min ∅ 4. Extrusion Line 5/8” – 2 1/4” VSWR The machine performance will mainly influence the return loss (VSWR). For our machine we guarantee best values for VSWR over the whole frequency range. Frequency range VSWR 10 – 1000 MHz ≤ 1.10 1000 – 1700 MHz ≤ 1.10 1700 – 2500 MHz ≤ 1.10 2500 – cut off MHz ≤ 1.35 4. Extrusion Line 5/8” – 2 1/4” VSWR Depending on the frequency operation range of RF cables from 5.5 MHz up to 3 GHz, error distances from 44 mm – 25 m will influence the cable quality. Therefor all line components like caterpillars, double disk capstan, pulleys, all motors and gears are not allowed to cause any periodically error in the mentioned range Variation line speed ≤ 0.1 % of setpoint Variation tensile force ≤ 5 % of setpoint Max. frequency peak ≤ - 60 dB% 4. Extrusion Line 5/8” – 2 1/4” VSWR RL(dB) VSWR Γ RL(dB) VSWR Γ RL(dB) VSWR Γ RL(dB) VSWR Γ 46.0 1.01 0.00498 26.0 1.11 0.0521 17.7 1.30 0.130 8.0 2.32 0.398 40.0 1.02 0.00990 25.0 1.12 0.0566 17.0 1.33 0.141 7.0 2.61 0.445 37.0 1.03 0.0148 24.0 1.13 0.0610 16.0 1.38 0.158 6.02 3.01 0.500 34.0 1.04 0.0196 23.5 1.14 0.0654 15.0 1.43 0.178 5.0 3.56 0.562 32.0 1.05 0.0244 23.0 1.15 0.0698 14.0 1.50 0.200 4.0 4.42 0.631 30.4 1.06 0.0291 22.0 1.17 0.0783 13.0 1.58 0.224 3.01 5.85 0.707 29.0 1.07 0.0338 21.5 1.18 0.0826 12.0 1.67 0.250 2.0 8.72 0.794 28.0 1.08 0.0385 20.7 1.20 0.0909 11.0 1.78 0.282 1.0 17.39 0.891 27.0 1.09 0.0431 20.0 1.22 0.100 10.0 1.92 0.316 0.5 34.75 0.944 26.4 1.10 0.0476 19.0 1.25 0.112 9.0 2.10 0.355 0.0 Infinity 1.00 4. Extrusion Line 5/8” – 2 1/4” VSWR Return Loss Voltage standing Wave Ratio Reflection Coefficient RL = -20*log|G| dB VSWR = G= 4. Extrusion Line 5/8” – 2 1/4” Attenuation Please note that the excellent line performance is only partly responsible for the achieved cable attenuation. The attenuation is mainly influenced by the used process materials for the dielectric. SIEBE is only responsible for the foaming process. We guarantee a homogeneous fine foam with closed cells and without holes, and a foam density ≤ 0.20 g/cm3, measured on samples of the cable production. 4. Extrusion Line 5/8” – 2 1/4” Production performance 1 5/8” Dielectric Physically foamed PE Density dielectric ≤ 0.20 g/cm3 OD dielectric 42.2 ± 0.5 mm Impedance 50 ± 1 Ω Capacitance 76 ± 0.5 pF/m Shorttime capacitance variations: ≤ ± 0.1 pF/m Eccentricity ≤ 0.30 mm Ovality ≤ 0.60 mm Attenuation at 20 °C: 0,5 – 1000 MHz 0.045 – 2.49 dB/100m Attenuation at 20 °C: 1000 – 1700 MHz 2.49 – 3.44 dB/100m Attenuation at 20 °C: 1700 – 2750 MHz 3.44 – 4.67 dB/100m VSWR: 10 – 2500 MHz: ≤ 1.10 4. Extrusion Line 5/8” – 2 1/4” RFS Pay-offs 4. Extrusion Line 5/8” – 2 1/4” RFS Sizing unit 4. Extrusion Line 5/8” – 2 1/4” RFS Ultrasonic cleaning station 4. Extrusion Line 5/8” – 2 1/4” Ultrasonic Wire Cleaning: Wire cleaning can be improved by means a new highly intensive ultrasound process. In this process very high ultrasonic power is concentrated in a small cleaning area, that surrounds the wire to be cleaned. This induces a very intensive field of caviation. The sound intensity amounts to more than thousands times the value reached by common ultrasonic baths. We offer that procedure in form of a fully automatic unit comprising a cleaning, rinsing and drying section. The compact machine will be provided with PLC interface, text display and automatic switching between the tanks. The machine is designed for 24/7 operation. Pre-Cleaning → Cleaning → Air-Wiping → Rinsing → Drying In case of heavy dirt, additional alkaline cleaning agents can be used. We recommend SurfaClean V149 from Kiesow GmbH & Co. KG, Germany. For further information for the ultrasonic cleaning station please see: www.hielscher.com For further information for the alkaline cleaning agent please see: www.kiesow.org 4. Extrusion Line 5/8” – 2 1/4” Sizing & Cleaning: To achieve good product quality, a well sized and clean conductor is required. If the conductor is not clean enough, an sizing and cleaning unit should be installed inline. Clean copper surface: → Reduced diameter and capacitance variations → Improved adhesion → Improved electrical transmission 4. Extrusion Line 5/8” – 2 1/4” RFS Double wheel capstan and pushing caterpillar 4. Extrusion Line 5/8” – 2 1/4” RFS HF preheating station and skinextruder 4. Extrusion Line 5/8” – 2 1/4” EUPEN Crosshead and calibration unit 4. Extrusion Line 5/8” – 2 1/4” EUPEN Foam extruder and gravimetric dosing station 4. Extrusion Line 5/8” – 2 1/4” RFS Foam extruder 4. Extrusion Line 5/8” – 2 1/4” Cooling trough 4. Extrusion Line 5/8” – 2 1/4” EUPEN Cable dryer, diameter gauge and length counter 4. Extrusion Line 5/8” – 2 1/4” EUPEN Pulling caterpillar and take-ups 4. Extrusion Line 5/8” – 2 1/4” 4.Extrusion Line 5/8” – 2 1/4” - C/D - PC 4. Extrusion Line 5/8” – 2 1/4” 4. Extrusion Line 5/8” – 2 1/4” SIEBE C/D plane: C/D plane is a simultaneous graphical display of final capacitance and diameter by a violett cross and its time history in green. The capacitance value is electronically delayed to coincide locally with the diameter measurement. A box centered around the setpoints of C and D indicates the tolerance field, inside which the trajectory of the process must stay to have good production, according to the setup limits. • Dark blue: Lines of constant extruder throughput / meter weight PE • Black Lines of constant foaming / dielectricity : • Light blue: Lines of constant gas flow The position of the actual measurement in reference to the dark blue solid line (line of constant amount of PE per length) indicates directly, whether the extruder output and expansion ratio are correct for the defined product properties: • Position of cross above line: → too much output / line speed to slow • Position of cross below line: → too little output / line speed to fast • Position of cross at line left of setpoint: → output o.k., not enough gas • Position of cross at line right of setpoint: → output o.k., too much gas The position along the dark blue line may be varied by changing gas amount, distance of cooling trough, wire temperature or melt temperature. The black lines are coordinates of constant expansion, along or parallel to which the process may be moved by varying the linespeed without changing extruder rpm and gas flow. The rlight blue lines are the curves of constant gas flow. To move along this coordinate, it is necessary to change extruder rpm, leaving gas flow and line speed unchanged. 4. Extrusion Line 5/8” – 2 1/4” Basic requirements for C/D plane: 1. Round insulation 2. High centrictiy 3. Density of used PE is stored in the computer 4. Dielectricity of used PE is stored in computer 5. Capacitance tubes and diameter gauges are calibrated correctly 4. Extrusion Line 5/8” – 2 1/4” 4. Extrusion Line 5/8” – 2 1/4” 4. Extrusion Line 5/8” – 2 1/4” 4. Extrusion Line 5/8” – 2 1/4” SIEBE FFT analysis and SRL prediction: The transmission characteristics of RF cable are most thoroughly described by the cable´s structural return loss (SRL). Typically the SRL is measured as a function of cable operating frequencies at the finished cable. With respect to SRL drop-outs, periodic cable parameter fluctuations are most critical. In the extrusion process, such variations might result from extruder fluctuations, imbalances of rotating parts, periodic line / capstan fluctuations, cyclic fluctuations in the foaming process, or periodic conductor pre-heating non-uniformities. In combination with the SIKORA measuring equipment the system allows to predict the SRL behaviour up to cable operating frequencies of 5 GHz.In connection with the SIKORA Capacitance 2060 the system allows the reliable detections of SRL peaks connected with periodic capacitance fluctuations having a magnitude of less than 3 fF/m. FFT spectrum analyses and SRL predictions based on diameter data can be conducted using SIKORA Laser 2100 diameter gauge or eccentricity unit Wandexe 2080. The system allow the reliable detections of SRL peaks connected with periodic diameter fluctuations in the nano-meter range. The SIEBE FFT / SRL system is developed at RFS, Germany. 4. Extrusion Line 5/8” – 2 1/4” 4. Extrusion Line 5/8” – 2 1/4” 4. Extrusion Line 5/8” – 2 1/4” 4. Extrusion Line 5/8” – 2 1/4” 4. Extrusion Line 5/8” – 2 1/4” 4. Extrusion Line 5/8” – 2 1/4”