G08 Group_8.ppt

advertisement

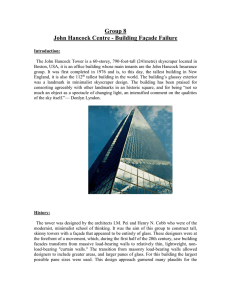

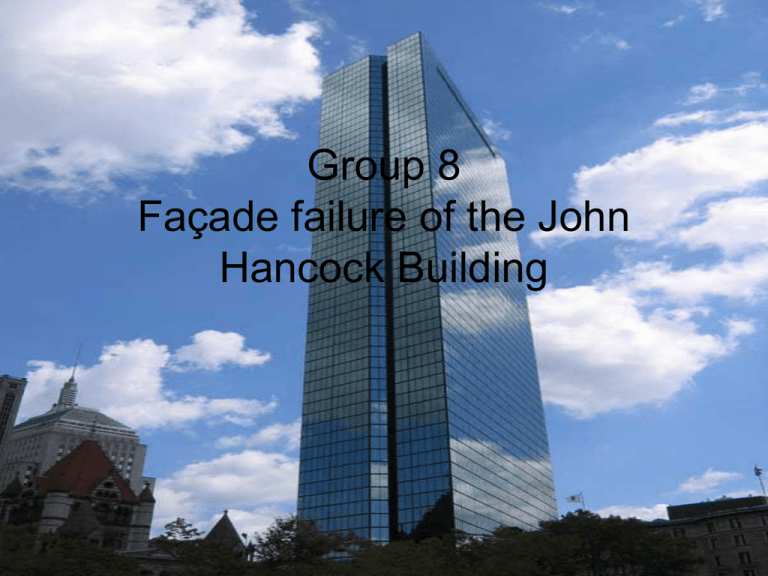

Group 8 Façade failure of the John Hancock Building “The Hancock” • Construction completed in 1976. • 241m high. • Tallest building in Boston and the135th tallest in the world. • It’s fully glazed façade was comprised of 10,344 windows. • American Institute of Architecture Award (1977) Problems with the Building • Budget overrun, $75m to $175m • Collapse of temporary retaining walls during excavation….This caused damage to nearby buildings, including the famous Trinity Church. • Motion Sickness experienced by people in the upper floors. A tuned mass damper costing $3m was installed on the 58th floor to combat the problem. Façade Failure!!! • January 20, 1973, building still under construction. • Winter Storm, gusts reaching 75mph at the upper floors. • The huge panels of glass, each weighing 500 pounds, fell off. • Holes were covered with sheets of painted black plywood. • Over the next few months, more windows kept falling off, nobody knew why! Incorrect theories • These theories erupted due a legal pact signed by all parties involved in it’s construction, not to disclose what really happened. • The tower was swaying too much. • The glass was sucked out by excessive wind forces at “hotspots” caused the sharp angles of the tower’s rhomboid shape. • The windows stressed when the tower’s foundations settled. What really happened • Each layer was a “sandwich”, two panes of glass with an air space in between held together with a metal frame. • To cut the glare and heat of the sun, the inside surface of the outside pane of glass was coated with a reflective coating of chromium. • The window frame was bonded to the chromium with a lead solder. • The lead solder was bonding too well with the glass!!! • Now the joint couldn’t absorb any movement! • But glass always moves as it expands and contracts with temperature and vibrates with the wind. • So the solder fatigued and cracked, and the crack continued through the glass. Solution • All 10,344 double-pane windows were replaced with single sheets of tempered glass. • The window maker covered the cost of $7m. • The 5,000 undamaged windows that were removed went on sale in bargain outlets in Boston at $100 each! Further Problems • The architect needed further assurance the building was safe, hired Thurlimann, the world’s leading authority on high-rise steel frame buildings. • He announced under entirely possible wind conditions, the building might fall over on it’s thin side, despite it being built to every structural code. • Solution: The tower was stiffened from its base to the top with 1,500 tonnes of diagonal steel braces costing $5m. Lessons learned • The problem with the glass façade was rectified and not used again in future design. • More research into structural behaviour. • Greater understanding of high rise structures due to the extensive testing the Hancock building underwent. The paradox • After all the testing the Hancock underwent, it must be one of the safest high rises in the world!