Effect of variation of member stiffness on behavior to timber... by Arne Bengt Riple

advertisement

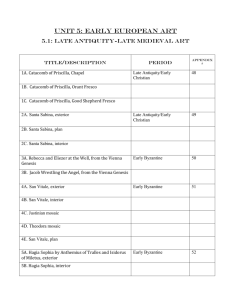

Effect of variation of member stiffness on behavior to timber bridge floor systems by Arne Bengt Riple A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science in Civil Engineering Montana State University © Copyright by Arne Bengt Riple (1985) Abstract: This paper investigates the effects incurred in a bridge floor system resulting from variation in member stiffnesses. If the stiffness in one stringer is reduced, without reducing the stiffness in the other members, a higher load must be carried by the nonreduced members. The increased loading condition results in reduced capacity for the floor system. The study is accomplished using a computer simulation to analyze the member reactions in the floor system. Using a structural grid as a model for the bridge floor, a matrix solution based on the stiffness method is solved by computer. Figures are presented to show the effects on member reactions resulting from variation in stiffness and loading conditions. Results show the effects occurring in both exterior and interior stringers as well as in the floor planks. The governing effects from these members are combined to show the effects in the floor system. Reducing the stiffness in an exterior stringer results in a greater reduce tion in capacity of the floor system, compared to reduction in capacity due to reduction in an interior stringer. EFFECT OF V A R IA T IO N OF MEMBER STIFFNESS ON BEHAVIOR OF TIM BER BRIDGE FLOOR SYSTEMS by Arne Bengt Riple A thesis submitted in partial fulfillment of the requirements for the degree of I Master of Science . in Civil Engineering M O NTA NA STATE U N IV E R S IT Y Bozeman, Montana June 1985 /V 3 7 g K4«5 C-op. % ii APPROVAL of a thesis submitted by Arne Bengt Riple This thesis has been read by each member of the thesis committee and has been found to be satisfactory regarding content, English usage, format, citation, bibliographic style, and consistency, and is ready for submission to the College of Graduate Studies. / W z /, / Date Chairperson, Graduate Committee Mpproveo ror me major Department // /9 < f6 Date Approved for the College of Graduate Studies (T Date Graduate Dean iii S TATEM ENT OF PERMISSION TO USE In presenting this thesis in partial fulfillment of the requirements for a master's degree at Montana State University, I agree that the Library shall make it available to borrowers under rules of the Library. Brief quotations from this thesis are allowable without special permission, provided that accurate acknowledgment of source is made. Permission for extensive quotation from or reproduction of this thesis may be granted by my major professor, or in his absence, by the Dean of Libraries when, in the opinion of either, the proposed use of the material is for scholarly purposes. Any copying or use of the materia1 ‘ .................. il gain shall not be allowed without my permission. Signature Date i l m s iv ACKNOW LEDGMENTS This research was made possible in part by support from the Engineering Experiment Station at Montana State University. The author expresses his appreciation to Dr. Fred F. Videon for the opportunity to conduct this study and for the guidance provided throughout the study. V TABLE OF CONTENTS Page A P P R O V A L .................................. ii S TATEM ENT OF PERMISSION TO USE............................................................................. jii ACK NO W LEDG M ENTS..................................................................... iv TABLE OF C O N TE N TS .............................. v L IS T O F TABLES................................................................ vi L IS T O F FIG URES.................................................................................................................... vii A B S T R A C T ................................................................................................................................ xi Chapter 1 IN T R O D U C T IO N ...................................................................................................... I Background.......................................................................................................... Objective............................................................................................................... I 2 2 ANA LYSIS OF FLOOR S Y S T E M ................................................... : .................. 3 3 R E S U LTS .................................................................................................................... 12 Bending in Stringers....................................................................... Reduced Stiffness in Center Stringer........................................................ Reduction in Exterior Stringer................................................................. Bending in Floor P lank...................................................................................... Reduced Center Stringer.............................................. Reduced Exterior Stringer.......................................................................... Combined Effects in F lo o r............................................................................... Deflection and Shear...................................................................... 12 12 16 21 30 30 30 41 4 SUM M A RY AND C O N C LU SIO N ....................................... 44 REFERENCES C IT E D ......................................................... 46 APPENDIX — Computer R uns....................................... 48 vi LIST OF TABLES Tables Page 1. Variation in Stiffness for the Grid Members........................................................... 5 2. Moment Capacity for Reduced S trin g er................................................................. 13 vii LIST OF FIGURES Figures Page 1. Grid model of floor system........................................................................................ 3 2. Bending moment in stringers at location of floor plank due to a unit load P at the exterior stringer............................................................................ 6 Bending moment in stringers at location of floor plank due to a unit load P at the first interior stringer................................................................... 6 Bending moment in stringers at location of floor plank due to a unit load P at the first interior stringer................................................................... 7 Bending moment in stringers at location of floor plank due to a unit load P at the second interior stringer.............................................................. 7 Bending moment in stringers at location of floor plank due to a unit load P at the center stringer............................................................................... 8 7. Bending moment in stringers at location of floor plank................ ...................... 8 8. Distribution of bending moment from the exterior stringer to first interior stringer................................................................................................... 10 Distribution of bending moment from first interior stringer to: ----- exterior stringer;-------- interior stringer........................................................... 10 Distribution of bending moment from second interior stringer to first interior stringer.................... 11 Distribution of bending moment from center stringer to second interior stringer............................................................................................................. 11 12. Reduction of stiffness in center stringer................................................................. 12 13. Reduced stiffness in center stringer. Effect in center stringer— IsZL = 32.7 in3 ..................................................................... 14 Reduced stiffness in center stringer. Effect in center stringer — IsZL = 22.2 in3 ................................................................... 14 Reduction of stiffness in center stringer. Effect in center stringer — IsZL= 16.8 in3 .......................................................................................................... 15 3. 4. 5. 6. 9. 10. 11. 14. 15. viii Figures 16. 17. 18. 19. Page Reduction of stiffness in center stringer. Effect on second interior stringer - ls/L = 32.7 in3 .......................................................................................... 17 Reduction of stiffness in center stringer. Effect in second interior stringer - ls/L = 22.2 in3 .......................................................................................... 17 Reduction of stiffness in center stringer. Effect in second interior stringer - ls/L = 16.8 in3 .......................................................................................... 18 Reduction of stiffness in exterior stringer. Effect in exterior stringer — IsZL = 32.7 in3.......................................................................................................... 19 20. Reduction of stiffness in exterior stringer. Effect in exterior stringer — IsZL = 22.2 in3 ............................................................................ 21. Reduction of stiffness in exterior stringer. Effect in exterior stringer — IsZL = 16.8 in3 .............................................................................................................. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 20 Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in first interior stringer — IsZL = 32.7 in3 ................................................... 22 Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in first stringer — IsZL = 22.2 in3 . ............................................................. 22 Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in first interior stringer — IsZL = 16.8 in3 ................................................... 23 Reduction of stiffness in exterior stringer. Load at first interior stringer. Effect in first interior stringer — IsZL = 32.7 in3 ..............; .................. 24 Reduction of stiffness in exterior stringer. Load at first interior stringer. Effect in first interior stringer — IsZL = 22.2 in3 ................................... 24 Reduction of stiffness in exterior stringer. Load at first interior stringer. Effect in first interior stringer — IsZL = 16.8 in3 ................................... 25 Reduction of stiffness in exterior stringer. Effect in first interior stringer from combined loading conditions — IsZL = 32.7 in3 ............................ 26 Reduction of stiffness in exterior stringer. Effect in first interior stringer from combined loading conditions - IsZL = 22.2 in3 ............................ 26 Reduction of stiffness in exterior stringer. Effect in first interior stringer from combined loading conditions — jsZL = 16.8 in3 ............................ 27 Moment diagram in floor plank. Load is located at exterior stringer................. 28 Load is located between the exterior and first interior stringer ................... 28 ix Figures 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. Page Moment diagram in floor plank. Load is located at center stringer. The effect of reduced center stringer is displayed.............................................. .. 29 Reduction of stiffness in center stringer. Effect in floor plank IsZL = 32.7 in3 ................................ .................................................................... ...... 31 Reduction of stiffness in center stringer. Effect in floor plank IsZL = 22.2 in3......................................................................................................... 31 .. Reduction of stiffness in center stringer. Effect in floor plank IsZL = 16.8 in3 ....................................... ................................................................ 32 Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in floor plank — IsZL = 32.7 in3 ....................... .......................................... 33 Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in floor plank — IsZL = 22.2 in3 ................................................................... 33 Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in floor plank - IsZL = 16.8 in3 ................................................................... 34 Reduction of stiffness in exterior stringer. Load between exterior and first interior stringer. Effect in floor plank - IsZL = 32.7 in3 ..................... 35 Reduction of stiffness in exterior stringer. Load between exterior and first interior stringer. Effect in floor plank - IsZL = 22.2 in3 ..................... 35 Reduction of stiffness in exterior stringer. Load between exterior and first interior stringer. Effect in floor plank - IsZL = 16.8 in3 ..................... 36 Reduction of stiffness in exterior stringer. Effect in floor plank due to combined loading conditions — IsZL = 32.7 in3 .............................................. 37 Reduction of stiffness in exterior stringer. Effect in floor plank due to combined loading conditions — IsZL = 22.2 in3 ......... ............... .................... 37 Reduction of stiffness in exterior stringer. Effect in floor plank due to combined loading conditions — IsZL = 16.8 in3 .............................................. 38 Reduction of stiffness in exterior stringer. Governing effect in floor system due to combined loading conditions - IsZL = 32.7 in3 ......................... 39 Reduction of stiffness in exterior stringer. Governing effect in floor system due to combined loading conditions - IsZL = 22.2 in3 ......... ............... 39 Reduction of stiffness in exterior stringer. Governing effect in floor system due to combined loading conditions — IsZL = 16.8 in3 .......................... 40 X Figures 49. 50. 51. Page Reduction of stiffness in interior stringer. Governing effects in floor system due to combined loading conditions — ls/L = 32.7 in3 .......................... 42 Reduction of stiffness in interior stringer. Governing effects in floor system due to combined loading conditions — ls/L = 22.2 in3 .......................... 42 Reduction of stiffness in interior stringer. Governing effects in floor system due to combined loading conditions — ls/L = 16.8 in3 . ; ..................... 43 xi ABSTRACT This paper investigates the effects incurred in a bridge floor system resulting from var­ iation in member stiffnesses. If the stiffness in one stringer is reduced, without reducing the stiffness in the other members, a higher load must be carried by the nonreduced mem­ bers. The increased loading condition results in reduced capacity for the floor system. The study is accomplished using a computer simulation to analyze the member reactions in the floor system. Using a structural grid as a model for the bridge floor, a matrix solution based on the stiffness method is solved by computer. Figures are presented to show the effects on member reactions resulting from variation in stiffness and loading conditions. Results show the effects occurring in both exterior and interior stringers as well as in the floor planks. The governing effects from these members are combined to show the effects in the floor system. Reducing the stiffness in an exterior stringer results in a greater reduc­ tion in capacity of the floor system, compared to reduction in capacity due to reduction in an interior stringer. I CHAPTER I IN TRO DUC TIO N Background Bridges are an important part of the United States road network. Over the last years, the traffic situation has become much heavier than many older bridges were designed for. In addition to the increased loading conditions, the bridges have also been deteriorating and several bridges are structurally deficient to handle present-day loading conditions [ I ] . This deficiency has proved to be a severe problem for many highway departments. The Federal Highway Administration (FHWA) [1] has worked together with the highway departments to find suitable solutions to solve these problems. Several methods of renova­ tion have been considered. A survey conducted by the author reveals that many highway departments feel that replacement of the older bridges is the best solution, and they are currently replacing the older bridges as soon as funding is available. As of 1981, based on a study by Koppers Co. [2] using a National Bridge inventory maintained by FHWA, over. 71,000 bridges in the U.S. used timber as a major material of construction. About 86% of these are off the Federal Aid system. Further, of the 297,566 off-system bridges of all materials and types, 33.4% were classified as structurally deficient and 27.4% were classified as functionally obsolete. It is reasonable to assume that the per­ centage for timber bridges are at least as high as these overall figures. Through personal communication with Don Harrison, Bridge Superintendent in Cas­ cade County in Montana [3 ], several aspects of bridge maintenance in the off-system were 2 discussed. Due to lack of funds the off-system bridges are seldom, replaced at the same rate as the Federal Highway bridges. One problem that was discussed is the deterioration of the top sides of the stringers due to trapped moisture between floor planks and stringers. As the top sides of the stringers deteriorate, the connection between stringer and floor plank tend to become insufficient. To obtain adequate connection between stringer and plank, the stringer has in several cases been turned upside down instead of being replaced. The effect of such a deteriorated stringer can be compared to a stringer with reduced volume, and thereby reduced stiffness. Objective The purpose of this research is to examine the effects on a bridge floor system due to reduction of stiffness in one stringer. The theoretical model of the floor system is discussed in Chapter 2. The effects of reduced stiffness in interior and exterior stringers are exam­ ined using the computer model. These effects are studied to determine the strength reduc­ tion of the bridge floor. 3 CHAPTER 2 ANA LYSIS OF FLOOR SYSTEM The floor system is analyzed using a structural grid as a model, as proposed by Ghali and Neville [4 ]. A structural grid is defined as a frame structure with rigid joints whose members and joints lie in a common plane, with all applied force loads being out of the plane and normal to the plane of the structure. The model grid is a rectangular system consisting of seven stringers and one floor plank as shown in Figure I. top view plank I I I I I I stringer end view Figure I . Grid model of floor system. "J_" member number; " I " joint number. 4 Plank decks consist of individual planks spiked across the stringers. Since the planks are not connected to each other, all bending in the longitudinal y-direction occur in the stringers. The use of one floor plank is therefore sufficient to examine the transverse dis­ tribution of bending moment in the floor system. For maximum bending effects in the stringers, the plank is located at the center of the stringers. A t the supports, the stringers are unrestrained for bending rotation about the x-axis, but are restrained for translation in the z direction and torsional rotation about the y-axis. To solve the structural grid, the stiffness method as presented by Weaver and Gere [5] is used. The theory behind the stiffness method is not discussed in this paper, but the computer program is listed in the Appendix. The dimensions used in the floor system are based upon requirements set by AASHTO [6 ]. To avoid the effects of buckling, the width to depth ratio, d/b = 2.0. From the length to depth ratio L/d = 15.0, the dimensions of the stringers are: b = 10.0 in d = 20.0 in The dimensions of the reduced stringers are: 1. b = 10.0 in d = 18.0 in 2. b = 10.0 in d = 16.0 in For the floor plank, the minimum thickness is 3.0 in. The width b of the floor plank is set to be 12.0 in, but the thickness is varied in one inch crements from 3.0 in to 6.0 in. According to these dimensions, the computer simulation is run with a variation in the member stiffness as shown in Table I . 5 Table I . Variation in Stiffness for the Grid Members. L/d Is/L (in3 ) IrsZL (in3 ) Ip/S (in3 ) 10.2 32.680 32.680 23.824 16.732 1.125 15.0 22.222 19.8 16.835 22.222 16.200 11.378 16.835 12.273 8.620 2.667 5.208 9.000 Is - moment of inertia of stringer; Irs = moment of inertia of deteriorated stringer; Ip = moment of inertia of floor plank; L = length of stringers; S = spacing of stringers; d = depth of stringer. The analysis of the grid is based on four loading conditions. A unit load P is individu­ ally placed at these locations: 1. Exterior stringer, joint 2 2. First interior stringer, joint 5 3. Second interior stringer, joint 8 4. Center stringer, joint 11 Each of these loading conditions give a set of influence lines that show the bending moment in each stringer, Figures 2-6. The bending moment in the loaded stringer is used as reference moment, and the bending moments in the other stringers are shown as a per­ centage of this reference moment. Figures 3 and 4 show the bending moment in the stringers at the location of the plank with the load P located at joint 5. In Figure 3 the curves show the variation in the stringer stiffness. Figure 4 shows the variation in the stiffness in the floor plank. Notice is Figure 4 that the bending moment in the exterior stringer for lp/S = 9.0 is actually greater than the bending moment in the loaded first interior stringer. The low stiffness in the stringers, ls/L = 16.8, allow large deflections, and the high stiffness in the 6 40.. - 12.0 ft 20. . Figure 2. Bending moment in stringers at location of floor plank due to a unit load P at the exterior stringer. Curves show the effect of variation in stringer stiffness. p r S I I T 1 0 0 .. 8 0 .. 6 0 .., - 2 0 .. 12.0 ft Figure 3. Bending moment in stringers at location of floor plank due to a unit load P at the first interior stringer. Curves show the effect of variation in stringer stiffness. 7 I I I I % no.. -1 6 .8 100.. 6 0 .. 4 0 .. 1 2 .0 ft Figure 4. Bending moment in stringers at location of floor plank due to a unit load P at the first interior stringer. Curves show the effect of variation in plank stiffness. p : r 100.. 6 0 -. 4 0 -- -20- . 12.0 ft Figure 5. Bending moment in stringers at location of floor plank due to a unit load P at the second interior stringer. Curves show the effect of variation in stringer stiffness. 8 p : r 100.. 12 .0 f t Figure 6. Bending moment in stringers at location of floor plank due to a unit load P at the center stringer. Curves show the effect of variation in stringer stiffness. Figure 7. Bending moment in stringers at location of floor plank. Curves show the varia­ tion in location of the unit load P. 9 floor plank make the floor system act with a higher rigidity. This results in larger deflec­ tion and higher bending moment in the exterior stringer than in the first interior stringer. As the stringer stiffness is increased, the distribution of bending moment from the loaded stringer to the adjacent stringer is reduced. This effect is reversed when looking at the stiffness in the plank. As the stiffness of the plank is increased, better distribution of bending moment is achieved. This capability of distributing the moment is important when looking at the effects of having a stringer with reduced stiffness. When designing the stringers for maximum bending moment, the exterior stringers are designed for a larger moment than the interior stringers. All interior stringers are designed for the same maximum bending moment. Figure 7 shows the four loading conditions and the difference in bending moment between exterior and interior stringers. When investigating the effects of a stringer with reduced stiffness, the greatest effects are noticed in the reduced stringer and the first adjacent stringer. Figures 8-11 show the percentage distributed bending moment from the loaded stringer to the first adjacent stringer. The curves show the effect of the variation in stringer and plank stiffnesses. As the stringer stiffness is decreased, more moment is distributed to the next stringer. This is reversed for the stiffness in the floor plank. Interpolation between the curves is possible for other magnitudes of member stiffness. When investigating the effects of having the stiffness in one stringer reduced, it is only necessary to reduce the center stringer and the exterior stringer. The reduction in the center stringer is representative for all interior stringers, whereas the exterior stringer has to be investigated separately. 10 J i L 3 2 .0 .: 2 8 .0 .. 2 4 .0 .. . .. 20 0 1 6 .0 .: 1 2 .0 .. 8 .0 .. 4 .0 .. 20 30 40 SO 60 70 80 80 100 Figure 8. Distribution of bending moment from the exterior stringer to first interior stringer. Load is located at exterior stringer. L 3 6 .0 .. 3 2 .0 2 8 .0 .. 2 4 .0 .. 2 0 .0 .. 16.0.: 1 2 .0 .. 8 .0 .. 4 .0 . . 20 30 40 SO 60 70 80 90 100 110 % Figure 9. Distribution of bending moment from first interior stringer to: ------- exterior stringer ------- interior stringer Load is located at first interior stringer. 11 H L lP 3 6 .0 . '" X s 3 2 .0 . 2 8 .0 . 2 4 .0 . 2 0 .0 . \ ^ \ \ \ - 1 6 .0 . 1 2 .0 . 8 .0 . 4 .0 . --------1--------1------- 1— 10 20 30 i--------;— 40 90 i------- 1---------1— 60 70 80 i--------1------------90 IOO X Figure 10. Distribution of bending moment from second interior stringer to first interior stringer. Load is located at second interior. Jj l L 3 6 .0 . —— — — — — — ^ QO \ Ol 3 2 .0 . 2 8 .0 . 2 4 .0 . \ 2 0 .0 . \ V A i.i' 1 6 .0 . 1 2 .0 . 8 .0 . 4 .0 . — I— 10 I— 20 I— 30 I— 40 i— 50 i— 60 i— 70 i— 80 I— 90 i------------100 % Figure 11. Distribution of bending moment from center stringer to second interior stringer. Load is located at center stringer. 12 CHAPTER 3 RESULTS Bending in Stringers Reduced Stiffness in Center Stringer When the stiffness in the center stringer is reduced, the two adjacent stringers must help carry the extra load the center stringer can no longer carry itself. The bending moment in the reduced center stringer is reduced whereas the bending moments in the two adjacent stringers are increased, Figure 12. p 100 . . 4 0 .. 2 0 .. 12 .0 ft Figure 12. Reduction of stiffness in center stringer. Curves show the effect in bending moment in stringers. Finding the governing effects of bending moment in the stringers requires two loading conditions. 13 1. unit force P at center stringer, joint 11. 2. unit load P at second interior stringer, joint 8 Reducing the stiffness in the center stringer results in decreased moment capacity for this stringer. This reduction in moment capacity must be considered when comparing the effects o f the change in bending moment in the stringers. The moment capacity in a stringer is given in Equation I . M = fb * sx ( I) For a stringer with reduced stiffness, the moment capacity is Mr = V sxr (2) The relationship between these two equations is (3) This gives The moment capacity for the reduced stringer used in this analysis is calculated using Eq. 4 and is listed in Table 2 as a function of IrsZls- Table 2. Moment Capacity for Reduced Stringer. IrsZIs 1.0 0.73 0.51 MrZM 1.0 0.81 0.64 With a reduction in stiffness to 51% of the full stiffness, the moment capacity is reduced to 64%. The governing effects of a load placed at the reduced center stringer is noticed in the center stringer. Figures 13-15 show the effects in the center stringer. The straight line 14 100.. 9 0 .. 80_. 60- 50- 40- _ 10- - 0.1 0.2 0.3 0.4 0 .5 0.6 0.7 0 .8 0 .9 1 0 I r s / ls Figure 13. Reduced stiffness in center stringer. Effect in center stringer — ls/L = 32.7 in3 100.. 8 0 - 6 0 .. 50 — 30-1. 20.1 0 .. 0.1 0 .2 0 .3 0.4 0.5 0.6 0.7 0.8 0 .9 1.0 Irs Z Is Figure 14. Reduced stiffness in center stringer. Effect in center stringer — ls/L = 22.2 in3 15 100.. 80 - 7 0 .. 6 0 .. 4 0 .. 3 0 .. 2 0 .. 10.. 0.2 0 .3 0.4 0 .5 0.6 0.7 0.8 09 1.0 I r s / l s Figure 15. Reduction of stiffness in center stringer. Effect in center stringer — I /L 16.8 in3. 16 represents the moment capacity of the stringer. When the moment curve is above the moment capacity, the effect of bending is increased in the center stringer. Measuring the difference between the moment curve and the moment capacity gives a direct indication of the reduction in capacity of the member. As the stiffness in the floor plank is increased, less effect in the reduced center stringer is noticed. The same effect is observed for the reduction in stringer stiffness. For the second loading condition, where the load is located at the second interior stringer, the governing effect is noticed in the second interior stringer. Figures 16-18. As the stringer has no reduction in stiffness, the moment capacity is constant at 100%. The moment capacity for the full stiffness stringer is indicated by a straight line at 100% in the figures. When the stiffness in the center stringer is reduced, deflection of the stringer will be increased. As the relative displacement between the reduced stringer and the main stringers is increased, the moment in the floor plank will also be increased. A higher stiffness in the floor plank will then transfer more moment to the adjacent stringers. High stiffness in the floor plank will therefore increase the effects in the adjacent stringers and reduce the effects in the reduced stringers. Reduction in Exterior Stringer Reducing the stiffness in the exterior stringer affects both the exterior and first interior stringers. To investigate the effects in the stringers, two loading conditions are used. 1. unit load P at exterior stringer, joint 2 2. unit load P at first interior stringer, joint 5 Since the exterior stringer does not have the advantage of having stringers on both sides, all distribution of forces go only in one direction. Because of this, the effects in the exterior stringer are more noticeable than in the center stringer. Figures 19-21 show the 17 200 - 180- 160- 140 - 120. - 100.. 8 0 .. 20.- 01 0.2 0.3 0.4 0.5 0.6 0.7 0 .8 0.9 1.0 Irs /ls Figure 16. Reduction of stiffness in center stringer. Effect in second interior stringer IsZL = 32.7 in3 . % 2 0 0 .. Y -22 .2 180- 1 6 0 .. 140- - 120.. i£. S 100-. 8 0 .. 60- - I 40- - ------ 1-------1------ 1------ 1------ f------1----- M— I------ 1-------- 1— 0.1 0 .2 0 .3 0 .4 0.5 0.6 0.7 0 .8 0.9 1.0 Irs /ls Figure 17. Reduction of stiffness in center stringer. Effect in second interior stringer IsZL = 22.2 in3 . 18 20 0 . . 1 8 0 .. 1 6 0 .. 1 4 0 .. 120.. 100.. 8 0 .. 6 0 .. 4 0 .. 20.. 0.1 0.2 0.3 0 .4 0.5 0 .6 0.7 0.8 0.9 1.0 IrsZ Is Figure 18. Reduction of stiffness in center stringer. Effect in second interior stringer — IsZL = 16.8 in3 . 19 100.. 9 0 .. 7 0 .. 5 0 .. 4 0 .. 3 0 -. 2 0 .. = 3 2 .7 1 0 .. 0.1 0.2 0 3 0 .4 0.5 0 .6 0.7 0.8 0 .9 1.0 I r s / ls Figure 19. Reduction of stiffness in exterior stringer. Effect in exterior stringer 32.7 in3. L /L s 100.. 8 0 .. 6 0 .. 3 0 .. = 0.1 0.2 22.2 0 .3 0.4 0.5 0.6 0.7 0 .8 0.9 1.0 I r s / ls Figure 20. Reduction of stiffness in exterior stringer. Effect in exterior stringer - L /L 22.2 in3. 20 100.. 9 0 .. 8 0 .. 6 0 .. 0.1 0 .2 0.3 0.4 OS 0.6 0.7 0 .8 0.9 1.0 IrsZ Is Figure 21. Reduction of stiffness in exterior stringer. Effect in exterior stringer — L /L = 16.8 in3. 21 changes of bending moment in the exterior stringer. The moment capacity is represented by the same line as for the reduced center stringer. When investigating the effects in the first interior stringer,, both loading conditions are considered. Figures 2 2-24 show the changes in bending moment for the first interior stringer when the load is located at the exterior stringer. Placing the load at the first interior stringer gives different results for the bending moment in the first interior stringer. Figures 25-27. As the stiffness in the stringers are reduced from 32.7 in3 to 16.8 in3, the governing effects change with the loading condition. With high stiffness in the stringers, the effect o f increased bending moment is governed by the second loading condition. This is reversed when the stringer stiffness is reduced. The combined effects of these two loading conditions must therefore be considered to find the maximum effects in the first interior stringer, Figures 29-31. Bending in Floor Plank Reducing the stiffness in a stringer results in increased deflections. This deflection creates higher bending moment in the floor plank, so it is important to investigate the effects in the floor plank the same way as for the stringers. To investigate the full effects, three loading conditions are used. Figures 31-33 show the moment distribution of the floor plank using these loading conditions. The maximum bending moment in the plank is used as reference for the percentage moment distribution. 22 200 . . -T - - 3 2 . 7 1 8 0 .. 1 6 0 .. 1 4 0 .. 120 . . 100.. 6 0 .. 20.. 0.1 0 .2 0 .3 0.4 0 .5 0 .6 0 .7 0 .8 0 .9 1.0 Irs Z Is Figure 22. Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in first interior stringer — ls/L = 32.7 in3 . 200.. 1 8 0 .. 1 6 0 .. 1 4 0 .. 120. . 100.. 6 0 .. 2 0 .. 0.1 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 0 .8 0 .9 1.0 I r s / ls Figure 23. Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in first stringer — IgZL = 22.2 in3. 23 200. . 1 4 0 .. 120. . 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 0 .8 0 .9 1.0 l r s/ Is Figure 24. Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in first interior stringer — ls/L = 16.8 in3 . 24 % 200. _ Y -3 2 .7 1 8 0 -. 1 6 0 .. 140- 120. . 100.. 80. _ 6 0 -4 0 .. 20. . 4------- 1------ V — Ol 0.2 0.3 0.4 as I--------H — \ ------- 1--------- 4 0 .6 ttS 0.7 09 1.0 Ir s /ls Figure 25. Reduction of stiffness in exterior stringer. Load at first interior stringer. Effect in first interior stringer — ls/L = 32.7 in3 . 200 - - 1 8 0 .. 1 6 0 .. 1 4 0 .. 120-100.. 0.2 0.3 0 .4 0.5 0.6 0.7 0.8 0 .9 1.0 Ir s / ls Figure 26. Reduction of stiffness in exterior stringer. Load at first interior stringer. Effect in first interior stringer — ls/L = 22.2 in3 . 25 200 - 1 8 0 .. 1 6 0 .. 1 4 0 .. 1 2 0 .. 100.. 8 0 .. 6 0 .. 4 0 .. 0.1 0.2 0.3 0.4 0.5 0 .6 0.7 0 .8 09 1.0 Ir s / ls Figure 27. Reduction of stiffness in exterior stringer. Load at first interior stringer. Effect in first interior stringer — ls/L = 16.8 in3 . 26 200 . . 1 8 0 .. 1 6 0 .. 140. _ 120. . 100.. 60. . 4 0 .. 0.1 0.2 0.3 0.4 0.5 0 .6 0.7 0.8 09 1.0 lr s /|s Figure 28. Reduction of stiffness in exterior stringer. Effect in first interior stringer from combined loading conditions — ls/L = 32.7 in3 . 200. . — =22 2 1 8 0 .. 1 6 0 .1 4 0 -. 1 2 0 .. 100.. 8 0 ._ 60. _ 4 0 .. 20- - 0.1 0.2 0.3 0.4 05 0.6 0.7 0 .8 0 .9 1.0 Ir s /ls Figure 29. Reduction of stiffness in exterior stringer. Effect in first interior stringer from combined loading conditions — IsZL = 22.2 in3 . 27 200.. 1 8 0 .1 6 0 .. (— 9 .0 L_ i .i ioo . 20. . 0.1 0.2 0.3 0.4 OS 0.6 0.7 0.8 0 .9 1.0 Ir s / ls Figure 30. Reduction of stiffness in exterior stringer. Effect in first interior stringer from combined loading conditions — ls/L = 16.8 in3 . 28 p r I I i i i 4 0 .. 12.0 ft 2 0 .. = 22.2 -6 0 .. - 8 0 .. - 100 . . Figure 31. Moment diagram in floor plank. Load is located at exterior stringer. I I— 100.. r -— I I I I I I I -iT =22.2 8 0 .. 6 0 ._ 2 0 ._ - 2 0 .. -4 0 .. 12.0 ft Figure 32. Load is located between the exterior and first interior stringer. 29 p 2 0 0 .. - ! f -2 2 .2 1 6 0 .. 120 .. -4 0 .. 1 2 .0 ft Figure 33. Moment diagram in floor plank. Load is located at center stringer. The effect of reduced center stringer is displayed. 30 Reduced Center Stringer The effect of reduced stiffness in the center stringer is showed by Figure 33. This reduction in stiffness increases the bending moment in the floor plank markedly. A load is located at the center stringer to create the governing effects in the floor plank as the center stringer is reduced. The increase in bending moment in the plank is shown in Figures 34-36. As for the stringers, the moment capacity is constant at 100%. Reduced Exterior Stringer When the stiffness in the exterior stringer is reduced, two loading conditions must be considered. The first location for the load is at the exterior stringer, Figure 31. The second location is at the center of the floor plank, between the exterior and first interior stringer. Figure 32. Figures 3 7-39 show the effects of the first loading condition and Figures 4 0-42 show the effects of the second loading condition. These two sets of curves are combined to give the maximum effect in the floor plank when the exterior stringer is reduced. Figure 43-45. Combined Effects in Floor The governing effects of a reduction of stiffness may be in any of the three investi­ gated members, depending on the member stiffnesses. . Figures 4 6 -4 8 show the effects of reduced stiffness in the exterior stringer. These curves are a combination of the maximum effects in the investigated members. The hori­ zontal line at 100% is the bending moment capacity of the floor system. The difference between the curves and the line of capacity is a direct measurement for the reduction in capacity of the floor system. 31 200.. 1 8 0 .. 1 6 0 .. 1 4 0 .. 120. . 100-8 0 .. 6 0 .. 4 0 .. 20.. 0.1 0 .2 0 .3 0.4 0 .5 0 .6 0.7 0 .8 0 .9 1.0 Irs /ls Figure 34. Reduction of stiffness in center stringer. Effect in floor plank - ls/L = 32.7 in3 . 200.. — = 22.2 1 8 0 .. 1 6 0 .. 1 4 0 .. 120.. 100.. 8 0 .. 6 0 .. 2 0 .. 0.1 0.2 0 .3 0.4 0 .5 0 .6 0.7 0 .8 0 .9 1.0 Ir s /ls Figure 35. Reduction of stiffness in center stringer. Effect in floor plank - ls/L = 22.2 in3. 32 200.. 1 8 0 .. 1 6 0 .. 1 4 0 .. 120.. 100.. 8 0 .. 20. - 0.1 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 0 .8 0 .9 1 .0 I r s / ls Figure 36. Reduction of stiffness in center stringer. Effect in floor plank — ls/L = 16.8 in3 . 33 3 2 .7 1 8 0 .. 1 6 0 .. 1 4 0 .. 1 2 0 .. 100.. 8 0 .. 6 0 .. 4 0 .. 0.1 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 0 .8 0 .9 1.0 I r s / ls Figure 37. Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in floor plank - ls/L = 32.7 in3. 200. . -Vl = 2 2 . 2 1 8 0 .. 1 6 0 .. 140. . 1 2 0 .. 100.. 8 0 .. 6 0 .. 20.- 0.1 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 0 .8 0 .9 1.0 I r s / ls Figure 38. Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in floor plank - Is/L = 22.2 in3. 34 2 0 0 .. 1 8 0 .. 1 6 0 .. 1 4 0 .. 1 2 0 .. 100.. 8 0 .. 6 0 .. 4 0 .. 20- - 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 0 .8 0 .9 1 .0 I r s / ls Figure 39. Reduction of stiffness in exterior stringer. Load at exterior stringer. Effect in floor plank — ls/L = 16.8 in3. 35 200-. 180. „ 1 6 0 .. 1 4 0 .. 120 . . 100.. 6 0 .. 4 0 .. 20. _ 0.1 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 0 .8 0 .9 1.0 I r s / ls Figure 40. Reduction of stiffness in exterior stringer. Load between exterior and first interior stringer. Effect in floor plank - ls/L = 32.7 in3 . 200-. 1 8 0 .. 1 6 0 -1 4 0 .. 120.. 100.. 8 0 -. 6 0 -. 0.1 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 0 .8 0 .9 1.0 I r s / l s Figure 41. Reduction of stiffness in exterior stringer. Load between exterior and first interior stringer. Effect in floor plank - ls/L = 22.2 in3. 36 200.. 1 8 0 .. 1 6 0 .. 1 4 0 .. 120. . 10 0. . 8 0 .. V . 9 .0 6 0 .. 4 0 .. 20.. 0.1 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 0 .8 0 .9 1.0 I r s / l s Figure 42. Reduction of stiffness in exterior stringer. Load between exterior and first interior stringer. Effect in floor plank — ls/L = 16.8 in3. 37 200. . -V - = 3 2 .7 1 8 0 .. 1 6 0 .. 1 4 0 .. 120. . 100 . . 8 0 .. 6 0 .. 2 0 .. 0.1 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 0 .8 0 .9 1.0 I r s / l s Figure 43. Reduction of stiffness in exterior stringer. Effect in floor plank due to com­ bined loading conditions — ls/L = 32.7 in3. 200.. -V - = 2 2 .2 1 8 0 -1 6 0 .. 140- - 120.. 10 0. . 8 0 .. 6 0 .. 4 0 .. 0.1 0 .2 0 .3 0 .4 0 .5 0 .6 0.7 0 .8 0 .9 1.0 I r s / ls Figure 44. Reduction of stiffness in exterior stringer. Effect in floor plank due to com­ bined loading conditions — ls/L = 22.2 in3. 38 200. . - V - = 1 6 .8 1 8 0 .. 1 6 0 .. 1 4 0 .. 120. . 100 - . 4 0 -. 0.1 0 .2 0 .3 0 .4 0 .6 0 .6 0 .7 0 .8 0 .9 1.0 I r s / l s Figure 45. Reduction of stiffness in exterior stringer. Effect in floor plank due to com­ bined loading conditions — ls/L = 16.8 in3. 39 200.. -V - = 3 2 . 7 18 0 . 1 6 0 .. 1 4 0 .. 120. . 100. . 80+ 60- 4 0 .. 0.1 0 2 0 .3 0 4 0 .5 0.6 0.7 0.8 0.9 1.0 Irs /ls Figure 46. Reduction of stiffness in exterior stringer. Governing effect in floor system due to combined loading conditions — ls/L = 32.7 in3. 200.. - 15- = 2 2 .2 1 8 0 .. 1 6 0 .. 1 4 0 .. 120. . 100 . . 4 0 -- 0.1 0 .2 0 .3 0.4 0.5 0 .6 0.7 0.8 0.9 1.0 Ir s /ls Figure 47. Reduction of stiffness in exterior stringer. Governing effect in floor system due to combined loading conditions — Is/L = 22.2 in3. 40 200 . . -V- =16 8 1 8 0 .. 1 6 0 .. 1 4 0 .. 120.. 100 . . 8 0 .. 0.1 0 .2 0 .3 0.4 0.5 0 .6 0.7 0 .8 0 .9 1.0 I r s / ls Figure 48. Reduction of stiffness in exterior stringer. Governing effect in floor system due to combined loading conditions — ls/L = 16.8 in3. 41 Figures 49-51 show the effects of reduced stiffness in the interior stringer. These curves display the same effect as Figures 4 6 -4 8 . Notice that the reduction in capacity is less for the reduction in interior stringer compared to the exterior stringer. Deflection and Shear To find the total effects in the floor system, increased effects in shear and deflection must also be considered. As the stiffness is reduced in a stringer, the deflection in this stringer will be increased. This, in turn, results in the floor plank having to carry increased load to the adjacent stringers. Deflection and shear are not as thoroughly investigated as the effects of bending. How­ ever, the analyses show that these effects are of about the same magnitude as the effects due to bending. Less, stiffness in the floor plank seems to increase the effects of both shear and deflec­ tion. Further analyses of the effects of shear and deflection are recommended. For the effect of shear in the stringers, the floor plank is suggested moved to the end of the stringers. 42 200 - - - f - -3 2 .7 1 8 0 -160- _ 1 4 0 .. 120- - 100. . 80- _ 60- _ 20- - 0.1 02 0 .3 0 .4 0 .5 0 .6 0.7 0.8 0 .9 1.1 Irs /ls Figure 49. Reduction of stiffness in interior stringer. Governing effects in floor system due to combined loading conditions — ls/L = 32.7 in3 . 200 - . 1 8 0 .. 1 6 0 .. 14 0 - 120. . 100- 80- _ 60+ 40420-. 0.1 0 .2 0.3 0.4 0 .5 0 .6 0.7 0.8 0.9 1.0 I r s / ls Figure 50. Reduction of stiffness in interior stringer. Governing effects in floor system due to combined loading conditions — ls/L = 22.2 in3. 43 200- -T- = 1 6 8 _ 1 8 0 .. 1 6 0 .. 1 4 0 .. 120. . 100.. 6 0 .. CU 0 .2 0 .3 0.4 0 .5 0 .6 0.7 0.8 0 .9 1.0 Ir s / ls Figure 51. Reduction of stiffness in interior stringer. Governing effects in floor system due to combined loading conditions - ls/L = 16.8 in3. 44 CHAPTER 4 SU M M A R Y AND CONCLUSION The results of this investigation are best separated into two categories. 1. effect in floor system due to reduced stiffness in exterior stringer 2. effect in floor system due to reduced stiffness in interior stringer Three members have been investigated for each reduction in stiffness and loading con­ dition. 1. stringer with reduced stiffness 2. first adjacent stringer to the reduced member 3. floor plank For each member and loading condition, three sets of curves have been developed. These curves show the increased bending moment in each member as a percentage of the maximum design moment for that specific member. A horizontal line at. 100% shows the maximum design moment for the floor plank and for a stringer having full stiffness. The reduced stringer has reduced moment capacity according to the reduction in section modulus. Table 2. It is evident that a reduction of stiffness in a stringer has adverse effects on the floor system. Reducing the stiffness of the exterior stringer results in a more severe reduction in the capacity of the floor system than if an exterior stringer is reduced. The effects on the floor system due to the reduction of member stiffness in one stringer depend on the combination of stiffnesses between the stringers and the planks. Reducing the exterior stringer depth from 20.0 in to 16.0 in reduces the capacity of the floor system by about 50% for ls/L = 16.8 in3 and lp/S = 9.0 in3, and by about 20% for 45 ls/L - 16.8 in3 and Ip/S - 1.1 in3. Lesser stiffness in the floor plank show less reduction of capacity for this condition. Reducing the center stringer depth from 20.0 in to 16.0 in reduces the capacity of the floor system by about 25% for ls/L = 32.7 in3 and lp/S = 9.0 in3, and by about 5% for ls/L = 22.2 in3 and IpZS = 1 . 1 in3 . As the stiffness in the stringers is reduced, less reduc­ tion of capacity is obtained with increased stiffness in the floor planks. It is recommended that the deteriorated stringers be replaced, and not simply turned over. If deteriorated stringers are turned over, the reduced depth of the stringer should be carefully examined, and the effects on the floor system should be investigated for the actual loading condition allowed on the bridge. 46 REFERENCES .CITED 47 REFERENCES CITED 1. Federal Highway Administration. "Upgrading deficient through truss bridges." FHW A/RD-82/041. Washington, D.C., April 1983. 2. Itani, R. Y ., and Faherty, K. F. "Structural wood research." ASCE. New York, New York, 1983. 3. Personal communication, Don Harrison, Bridge Superintendent in Cascade County. February 1985. 4. Ghali, A., and Neville, A. M. "Structural analysis, a unified classical and matrix approach." 2nd edition. Chapman and Hall, London, 1978. 5. Weaver, W. Jr., and Gere, M. M. "Matrix analysis of framed structures." 2nd edition. D. Van Nostrand Company, New York, 1980. 6. American Association o f State Highway and Transportation Officials. "Standard spec­ ifications for highway bridges." AASHTO . 12th edition. Washington, D.C. 1977. 48 APPENDIX COMPUTER RUNS 49 12:05 J UN o ribsle I? a on ! E GRI DA E D I T S03 I .000 2.000 3.000 4 .000 5.000 6.000 7.000 8.000 9.000 10.000 11 . 0 0 0 12.000 13.000 14.000 15.000 16.000 17.000 13.000 19.000 20.000 21.000 22.000 23.000 24.000 25.000 26.000 27.000 28.000 29.000 30.000 31 . 0 0 0 32.000 33.000 34.000 35.000 36.000 37.000 38.000 39.000 40.000 4 1 . OQO 42.000 43.000 44.000 45.000 46.000 47.000 48.000 49.000 50.000 51.000 52.000 53.000 54.000 55.000 56.000 '85 L E N E . I CE F V 0 0 5 11:42 04/12/85 HERE C C C C C C ************************************ ************************ * * GRI D PROGRAM, NAMED I C E F V C 0 3 , RI PLE 483 640 460 720 * * * * * * * ** * * ** * ** * * ** * ** * * ** * * ** * ** * * ** * ** * * ** * * ** * ** * * ** * * ** * * DI ME NS I ON DI MENSI ON DI I E N S I ON DI MENSI ON DI MENSI ON C C C GRI D INPUT X ( 1 0 0 ) , Y ( I 0 0 ) , J J ( I 0 0 ) , J K ( I 0 0 ) , X I (5 0 ) , Y I ( 5 0 ) A ML ( 6 , 5 0 ) , J R L ( 3 0 0 ) , E L ( 5 0 ) , C X ( 5 0 ) , C Y ( S O ) I D ( 3 0 0 ) , S F F ( 3 0 0 , 1 0 0 ) , S M S ( 6 , 6 ) , I M ( 6 ) , LML( SO) AR(300),AE(300),AJ(300),AC(300),OJ(500),DF(300) A M 0 ( 4 ) , K ( I O O ) , A M ( 6 ) , K 9 ( 1 0 0 ) , KC( SO) STATEMENTS I SN = I I C HNGE = O W R I T E * , " F O R PRESET GR I D P R I N T I , ELSE 0 " I N P U T PRESET I F ( P R E S E T . EU. 0 ) GOTO 6 3 0 W R I T E * , " I N P U T NUMBER OF S T R I N G E R S " I N P U T NST W R I T E * , " I N d UT LENGTH OF S T R I N G E R S " I N d UT ST L W R I T E * , " I N P U T S P A C I N G OF S T R I N G E R S " I N P U T STS WR I T E * , " I NRUT DEPTH D, AND WI DTH B ( i n ) OF S T R I N G E R S " I N P U T O S , BS W R I T E * , " I N P U T DEPTH D, AND WI DTH B ( i n ) OF P L A N K " INP UT DP,BP W R I T E * , " I N P U T D I M E N S I O N S OF REDUCED STRI NGER , D AND B ( i n ) " I N P U T R OS , RBS WR I T E * , " I NPUT L O C A T I O N OF REDUCED S T R I N G E R , S T R I N GE R NUMBER" I N P U T RST W R I T E * , " I N DUT L O C A T I O N OF P L A N K , AS F RACTI ON OF S T R I N G p R L ENGT H" I NPUT LFP W R I T E * , " I N P U T E AND G" I NPUT E , G WR I T E * , " I N d UT NUMBER OF LOADED J O I N T S ( N L J ) , AND" W R I T E * , " N U M B E R OF L OADED MEMBERS ( N L M ) " I N d UT N L J , NLM W R I T E * , " I N D'JT NUMBER OF R E S T R A I N T S ( NR ) " I N P U T NR W R I T E * , " I N P U T NUMBER OF R E S T R A I N E D J O I N T S ( N R J ) " I N P U T NRJ STSI=STS*12 S TL I = S TL * 1 2 NJ=i*NST M = ( 3* NS T ) - 1 ND J = 3 NO = NOJ * N J N=ND-NR DO 7 2 0 J = I , ND AR(J)=O.C AE(J)=O.C C ON T I N U E DO 7 3 0 1 = 1 , M 50 57.000 55.000 59.000 60.000 61.000 67.000 63.000 64.000 65.000 750 66.000 67.000 68.000 69.000 70.000 71 . 0 0 0 72.000 73.000 74.000 75.000 76.000 77.000 78.000 79.000 80.000 81 . 0 0 0 82.000 83.000 84.000 85.000 86.000 87.000 88.000 89.000 90.000 91 . 0 0 0 92.000 93.000 94.000 95.000 96.000 97.000 98.000 99.000 700 I 0 0 .00 0 I 01 . 0 0 0 I 02.000 I 03.000 I 04.000 105.000 I 06.000 I 07.000 I 08.000 I 09.000 110.000 111.000 I 12.000 113.000 I 14.000 115.000 I 16.000 I 17.000 73? 710 661 LIL(I)=O-O C ONT I NUE XST=<3S*CDS**3)+DS*(0$*»3))/12 YST=RS* ( 0 S * « 3 ) / 1 2 XFDa(gp*(DP**3)+DP*(8P**3))/12' Y FP = B d * ( D P * * 3 > / I 2 X R S T = C R B S * ( RDS* * 3 ) + R D S * < R B S * * 3 ) ) / 1 2 YRST=RBS*(R0S**3)/12 NK = NJ KXO=O.0 DO 7 0 0 I = 1 / N K , 3 X(I)=KXO X(I*1)=KX0 X ( I + 2 ) = KX0 Y(I)=O.O Y(I+1)=STLI/LFP Y ( I + 2 ) = STLI KXO = KXO T S T S I JJ(I)=I JK(I)=ITl JJ(ITl)=ITl JK(ITl)=ITE XI(I)=XST XI(ITI)=XST YI(I)=YST Y I ( I T 1 ) =YST IF d . L T . NK) THEN J J ( IT 2 ) =ITl J K ( I T ? ) = IT4 X I (IT?)=XFP Y I (IT?)=YFd ENDI F C ONT I NUE JP=3*RST XI(JP-I)=XRST Y I ( J P - I ) =YRST X I ( J P - 2 ) =XRST YI(JP-Z)=YRST WRITE*," " I F ( I CHNGE . GT . 0 ) THEN W R I T E * , " I F ANY CHANGES HAS BEEN MADE TO THE RE ST R A I N E D J OI N T S W R I T E * , " CHANGES MUST RE RECORDED I N THE J O I N T R E S T R A I N T L I S T . W R I T E * , " P R I N T I TO PERFORM THESE CHANGES, P R I N T O TO CONTI NUE I N d UT CHJRL I F ( C H J R L . EQ. 0 ) GOTO 661 ENDI F DO 7 3 2 J = 1 , NO JRL(J)=O C ONT I NUE W R I T E * , " I N P U T J OI NT RESTRAI NT L I S T " WRITE*,"K,JRL(3K-2>,JRL(3K-1),JRL(3K)" DO 7 1 0 1 = 1 , NRJ I NPUT K ( I ) , J R L ( 3 * K ( I ) - 2 ) , J R L ( 3 * K ( I ) - D , J R L ( 3 * K ( I ) ) CONT I NUE I F ( I CHNGE . GT. 0 ) THEN W R I T E * , " I F ANY CHANGES HAS BEEN MADE TO THE J O I N T L O A D S , " W R I T E * , " T H E N CHANGES MUST BE RECORDED" W R I T E * , " P R I N T I TO PERFORM THE CHANGES, P R I N T O TO C ON T I N U E " I N P U T CHJ L I F ( C HJ L . E Q . 0 ) GOTO 6 6 2 ENDI F 51 I I S . 000 I 19.000 120.000 733 I 21 . 0 0 0 I 22.000 I 23.000 I 24.000 I 25.000 1 2 6 . 0 0 0 74 4 I 27.000 1 2 8 . 0 0 0 662 129.000 I 3 0 . 0 00 I 31 . 0 0 0 I 32.000 I 33.000 I 34.000 I 35.000 I 36.000 I 37.000 I 3 8 . 0 0 0 735 I 3 9 , 0 0 0 734 I 40.000 141.000 I 42.000 I 43.000 I 44.000 I 45.000 I 4 6 . 0 0 0 745 I 47.000 I 4 3 . 0 0 0 663 I 49.000 I 50.000 I 51 . 0 0 0 I 52.000 I 53.000 I 54.000 I 55.000 I 56.000 I 57.000 C I 5 8 . 0 00 6 3 3 I 59.000 I 60.000 I 61 . 0 0 0 I 62.000 I 63.000 I 64.000 I 65.000 I 66.000 I 67.000 C I 69.000 C I 69.000 C I 70.000 I 71 . 0 0 0 I 72.000 I 73.000 I 7 4 . 0 0 0 350 I 75.000 I 76.000 I 77.000 I 7 9 . 0 0 0 370 DO 7 33 J * I / ND A J ( J ) = O 1C C ONT I NUE I F C N L J . N E . 0 ) THEN W R I T E * , " I N P U T J O I N T L OA D S " WR I T E * , " K , A J ( 3 K - 2 ) , A J ( 3 K - 1 ) , A J ( 3 K ) " DO 7 4 4 1 = 1 , NLJ I NPUT K 9 ( I ) , A J < 3 * K 9 ( I ) - 2 ) , A J ( 3 » K B < I ) - 1 ) , A J < 3 * K d ( I ) > C ONT I NUE ENDI F I F d C H N G E . GT. 0 ) THEN W R I T E * , " I F ANY CHANGES HAS BEEN MADE TO TH E MEMBER L O A D S , " W R I T E * , " T H E N THESE CHANGES MUST BE RECORDED" W R I T E * , " P R I N T I TO RECORD THE CHANGES, P R I N T O TO C ON T I N U E " I N P U T CHML I F ( CHML . E R . 0 ) GOTO 6 6 3 ENDI F DO 7 3 4 1 =1 , M DO 7 3 5 J = 1 , 6 AML( J , I > = 0 . 0 C ON T I N U E CON T I N U E I F ( NLM . N E . 0 ) THEN W R I T E * , " I NPUT MEMBER L OA D S , I , A M L ( I , I ) , A M L ( 2 , I ) , A M L < 3 , I ) " WRITE*,"AML(4,I),AML(5,I),AML(6,I>" DO 7 4 5 1 = 1 , NLM I N P U T K C ( I ) , AML ( 1 , K C ( I ) ) , A M L ( 2 , K C ( I ) ) , A M L ( 3 , K C ( I ) ) , A M L ( 4 , K C ( I ) ) , * AML ( 5 , KC ( I ) ) , A ML ( 6 , K C ( D ) C ONT I NUE ENDI F WR I T E * , " * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * W R IT E *,"*************************+***********.******.**,***+.. LOD=STLI/DS WRITE*,"SPACING*",STS WRITE*,"L/D= ",LOD W R I T E * , " M A I N S T RI NGERS : " , R S , " * " , OS W R I T E * , " R E D U C E D ST RI NGE RS : " , RB S , ” * " , RDS WRITE*,"PLANK :",0°,"*",B P GOTO 6 9 9 WRITE*,"INPUT WRITE*," " WRITE*," " STATEMENTS START" WRITE*,"INPUT M,NJ,NR,NRJ,E,G" I NPUT M , N J , N R , N R J , E , G WRITE*," " NO J = 3 ND = NDJ * N J N= ND- NR CLEARI NG MATRI XES DO 35 0 J = 1 , ND AR(J)=O1C AJ(J)=O1C A E ( J )= O 1C C ONT I NUE DO 3 6 3 1 = 1 , M DO 3 7 0 J = I , 6 AM L ( J , I ) = 0 . 0 CON T I N U E 52 I 79.000 I 8 0 . 0 0 0 360 I 81 . 0 0 0 I 82.000 I 8 3 . 0 0 0 17 0 184.000 C I 85.000 C I 86.000 C I 87.000 I 88.000 I 89.000 I 9 0 . 0 0 0 I OO I 91 . 0 0 0 192.000 I 93.000 I 94.000 1 9 5 . 0 0 0 110 I 96.000 I 97.000 I 98.000 I 99.000 2 0 0 . 0 0 0 120 2 C l .000 202.000 203.000 204.000 205.000 206.000 207.000 2 0 8 . 0 0 0 130 209.000 210.000 211.000 2 1 2 . n 00 213.000 214.000 2 1 5 . 0 0 0 140 216.000 217.000 C 218.000 C 219.000 C 2 2 0 . 0 0 0 699 221.000 222.000 223.000 I 224.000 225.000 2 226.000 227.000 228.000 229.000 3 230.000 231.000 232.000 4 2 3 3 . 0 0 0 150 2 34.000 235.000 236.000 23 7 . 0 00 238.000 239.000 5 L M L ( I ) = O. O CON T I N U E DO I 7 0 J = I , NO JRL(J)=O C ONT I NUE CONTI NUATI ON OF I NPUT WRITE*,"INPUT X ( J ) , Y ( J ) " DO I OO J = I , NJ I NPUT X ( J ) , Y ( J ) C ONT I NUE WRITE*," " WRITE*,"INPUT J J ( I ) , J K ( I ) , X I ( I ) , Y I ( I ) " DO 1 1 0 1 = 1 , M I NPUT JJ ( I ) , J K d ) , XI ( I ) , Y K I ) C ONT I NUE WRITE*," " WRITE*,"INPUT K , J R L ( 3 * K - 2 > , J R L ( 3 * K - 1 ) , J R L ( i * K > " DO I 21 1 = 1 , NRJ I NPUT K ( I > , J R L ( 3 * K ( I ) - 7 > , J R L ( 3 * K ( I > - 1 ) , J R L ( 3 * < ( I > > C ONT I NUE WRITE*," " WR I T E * , " I N P U T NL J , NL M" I N P U T N L J , NLM WRITE*," " WRITE*,"INPUT K , A J ( 3 * K - 2 ) , A J ( 3 * K - 1 > , AJ(3*K>" DO I 30 1 = 1 , NLJ I NPUT K 9 ( I ) , A J ( 3 * K 8 ( I ) - 2 ) , A J ( 3 * K B ( I ) - 1 ) , A J ( 3 * K 9 ( I ) ) CON T I N U E WRITE*," " W R I T E * , " I N P U T I , AML( I , I ) , A ML ( 2 , I ) , A ML ( 3 , I ) , A M L ( 4 , I ) *AML(6,I)” DO I 4 0 1 = 1 , NLM ,I), I NPUT K C ( I ) , A M L ( 1 , K C ( I ) ) , A M L ( 2 , K C ( I ) ) , A M L ( 3 , K C ( I ) ) , *AML(5,KC(I)),AM L(6 ,KC(I)) CON T I N U E WRITE*," " KC( I ) ) , SDATA 4 WRITE*," " WRI TE*, "STRUCTURAL WRITE(108,1) PARAMETER S" F0RMAT(6X,"M",4X,"N",3X,"NJ",3X,"NR",2X,"NRJ",8X,"E WRITEd 08,2)M,N,NJ,NR,NRJ,E,G F0RMAT(2X,5I5,2F9.2) WRITE*," " W R I T E * , " J O I N T C OOR D I N A T E S " WRITE(108,3) FORMAT(2X,"JOINT” , 9 X , " X " , 9 X , " Y " ) DO I 50 J = I , NJ WR I T E d 0 8 , 4 ) J , X ( J ) , Y ( J ) F0RMATC2X,I5,2F10.5> C ONT I NUE WRITE*#" " WR I T E * , " ME M3 E R I NFORMATI ON" WRI T E ( I 0 8 , 5 ) FORMAT!2X,"MEMSER",2X,"JJ",3X,"J K " , 8 X , " X I " , 3 X , " Y I " , R X , *"EL",SX,"CX",3X,"CY") MD = 2 * N D J fi ") 53 ?40.mo 2 4 1 .onn 2 4 2 . non 243.000 244.000 245.000 246.000 247.000 248.000 249.000 250.000 251.000 252.000 253.000 254.000 255.000 256.000 257.000 258.000 259.000 260.000 261.000 262.000 263.000 264.000 265.000 266.000 267.000 268.000 269.000 270.000 271.000 272.000 273.000 2 7 4 . 0 00 275.000 276.000 277.000 278.000 2 7 9 . 0 00 280.000 281.000 282.000 283.000 284.000 285.000 286.000 287.000 288.000 289.000 290.000 291.000 292.000 293.000 294.000 295.000 296.000 297.000 298.000 299.000 300.000 NB = O DO I 6 0 1 = 1 , M NB I = NOJ * < AB S ( J K ( I ) - J J d ) ) + ! ) I F ( N 9 I . GT. NB) NB = NBI XCL = X ( J K ( I ) ) - X ( J J d ) ) YCL = Y U K ( D ) - Y ( J J d ) ) E L ( I ) =SQRT( XCL*XCL+YCL*YCL) CX( D = X C L Z E L ( I ) CY ( D = Y C L Z E L ( I ) 6 160 7 8 181 190 C C C 21 O 200 W R I T E d O 8 , 6 ) 1 , J J ( I ) , J K ( I ) , X I ( D , Y I ( I ) , EL ( I ) , C X ( I ) , C Y ( I ) F0RMAT(2X,3I5,5F10.3) CON T I N U E WRITE*," " W R I T E * , " J O I N T RESTRAI NTS" WRITE(108,7) F ORMAT ( 2 X , " J 0 I N T " , 2 X , " J R 1 " , 2 X , " J R 7 " , 2 X , " J R 3 " ) DO 1 80 I = D N R J W RITE(108,S)K(D,JRL(3*K(D-2)»JRL(3*K(I)-1),JRL(3*K(I)> FORBAD 2 X , 415) CON T I N U E WRITE*," " NI =O DO 1 9 0 J = D N D NI=NDJRL(J) I F ( J R L C J ) . GT. 0 ) THEN I D ( J ) = N + NI ELSE ID(J)=J-NI ENDI F C ONT I NUE STIFF 4 DO 2 0 0 J = D N DO 2 1 0 K A = I , NB SFF ( J , K 4 ) = 0 . 0 CON T I N U E CONT I NUE DO 2 2 0 1=1, 14 SC M IaG iX K D ZEL(I) S C M 2=4.0*E *YI(D ZEL(I) S C M3 = 1 . 5 * S C M 2 Z E L ( I ) SCM4 = ? . 0 * S C i M 3 Z E L ( D S M S ( D I ) = S C M 1 * C X ( D * C X ( D +S C "42 * C Y ( D * C Y ( I ) S M S ( D 2 ) = ( S C MI - S C M2 ) * C X ( D * C Y ( D SMS(1,3)=SC43*CY(D S M S ( D 4 ) = - S C M 1 * C X ( I ) * C X ( I ) +0 . 5 * S C M 2 * C Y ( D * C Y ( D SMS(D5)=-(SCMD0.5*SCM2)*CX(I)*CY(I) SMS ( 1 , 6 ) = - S M S ( D 3 ) S MS ( 2 , 2 ) = S C M I * C Y ( I ) * C Y ( I ) + S C M 2 * C X ( I ) * C X ( I ) SMS( 2 , 3 ) = - S C M 3 * C X ( D SMS ( 2 , 4 ) = S M S d , 5 ) S M S ( 2 , 5 ) = - S C M D C Y ( I D C Y d ) + n . 5 * S C M2 * C X ( I ) * C X ( D SMS ( 2 , 6 ) = - S M S ( 2 , 3 ) S MS ( 3 , 3 ) = S C M4 S MS ( 3 , 4 ) =SMSC I , 3 ) S 4S(3,5)«SMS(2,3> S MS ( 3 , 6 ) = - S CM4 S M S ( 4 , 4 ) = SMS( I , 1 ) SMS ( 4 , 5 ) = S M S ( D 2 ) SMS ( 4 , 6 ) = S M S d , 6 ) 54 i Cl . n o n 302.000 303.030 304.000 305.000 306.000 307.000 308.000 309.000 310.000 311.000 312.000 313.000 314.000 315.000 316.000 317.000 318.000 319.noo 320.000 321.000 322.000 323.000 324.000 3 2 5 . 0 0 0 240 3 2 6 . 0 0 0 230 3 2 7 . 0 0 0 770 328.000 329.000 C 330.000 C 331.000 C 337.000 333.000 334.000 335.000 336.000 337.000 338.000 339.000 340.000 341 . 0 0 0 342.000 343.000 3 4 4 . 0 0 0 410 345.000 3 4 6 . 0 0 0 400 3 4 7 . 0 0 0 601 348.000 349.000 350.000 351.000 3 5 2 . 0 0 0 470 353.000 354.000 3 5 5 . 0 0 0 390 356.000 C 357.000 C 358.000 C 359.000 C 360.000 C 361.000 SMS C 5 , 5 ) = S M S ( 2 , 2 ) SMS( 5 , 6 >= S M S ( 2 , 6 ) S M S ( 6 , 6 > =SCM4 IM (1 )= 3 *JJ(I)-2 IM (2 )= 3 *JJ(I)-1 IM (3)=3*JJ(I) IM (4)-3 *JK (I)-2 IM (5)=3*JK (I)-1 I.M (6>*3*JK(I> DO 2 3 0 J = 1 ,MD II= IM (J) I F ( J R L t I I ) . GT . 0 ) GOTO 2 3 0 DO 2 4 0 K A = J ,MD I2=IM (K A) I F ( J R L ( I 2 ) . GT . 0 ) GOTO 2 4 0 IR = ID (II) IC = ID (IZ ) I F d R . G T. I O THEN ITEM=IR IR = IC I C = I TEM EN DI F IC =IC -IR tI S F F U R ,I O =S F F U R ,IO tS M S U , C ON T I N U E CON T I N U E CON T I N U E N R ITE*," " BANFAC I F ( S F F ( 1 , 1 ) . L E . 0 . 0 ) GOTO < DO 3 9 0 J = 2 , N JI=J-I J2=J-NBt1 I F ( J 2 . L T. I ) J2 = 1 I F ( J I . EQ. I ) GOTO 601 DO 4 0 1 1 = 2 , J l II= I-I I F ( 1 1 . L T . J 2 ) GOTO 4 0 0 SU' 4 = SFF ( I , J - I t l ) DO 4 1 3 K A = J Z , I l SU M= SUM- SFF( K A , I - K A t I ) * S F F ( K C ON T I N U E SFF ( I , J - I t D =SUM CON T I N U E SUM=SFF( J , 1 ) DO 4 2 0 KA = J Z , J I TEMP=SFF( K A , J - K A t I ) / S F F ( K A , I SUM = S U M - TEMP» S F F ( K A , J - K A t I ) S F F ( K A , J - K A t I ) =TEMP CONT I NUE I F ( S U M . L E . 0 . 1 ) GOTO 6 0 0 S F F ( J , I ) =SUM CON T I N U E LDATA 4 WR I T E * , " STRUCTURE NO." , I S N KAtl ) 55 162.000 363.000 364.000 365.000 366.000 367.000 368.000 369.000 370.000 371.000 372.000 373.000 374.000 375.000 376.000 377.000 378.000 379.000 380.000 381.000 382.000 383.000 384.000 385.000 386.000 387.000 388.000 389.000 390.000 391.000 392.000 393.000 394.000 395.000 396.000 397.000 398.000 399.000 400.000 401.000 402.000 403.000 404.000 4 05.000 406.000 407.000 408.000 409.000 410.000 411.000 412.000 413.000 414.000 415.000 416.000 417.000 418.000 419.000 420.000 421.000 422.000 O 10 11 12 250 I 3 14 260 C r C 270 280 C C C WRITEd 0 8 ,9 ) FORMAT( 4 X , " N L J " , 2 X , " N L ^ " ) WR I T E ( I 0 8 , 1 0 ) N L J , N L M F O R M A T ! 2 X , 2 I 5) W RITE*," " I F C N L J . N E . 0 ) THEN W R I T E * , " A C T I O N S AT J O I N T S " WR I TEC I 0 8 , 1 1 ) F0RMATC2X," J O I N T " , 7 X , " A J I " , 7 X , " A J 2 " , 7 X , " A J 3 " ) DO 2 5 0 J = I , N L J W R ITEC 108,12)K8C J),A JC 3*K B C J)-2),A JC 3*K B C J)-1),A JC 3*KB C J)) F0RMATC2X,I5,3F10.3) C ON T I N U E END I F W RITE*," " I F C N L M . N E . 0 ) THEN WR I T E * , " A C T I O N S AT ENDS OF R E S T R A I N E D MEMBERS DUE TO LOADS WRITEC108,13) FORMAT!2X,"MEMBER",5 X , " AMLI" , 6 X , " A M L 2 " , 6 X , " AML3 " , 6 X , " A M L 4 " *6X ,"A M L5",6X ,"A M L6") DO 2 6 0 1 = 1 , NLM W R I T E C 1 0 8 , 1 4 ) K C ( I ) , A M L C 1 , K C ( I ) ) , AMLC2,K C C I ) ) , AMLC3,K C C I ) ) , *AM L(4,KC C I)),AM LC 5,KC C I)),AM LC 6,KC C I)) F0RMATC2X,I5,6F10.3> LMLCKCCI ) ) = 1 C ON T I N U E W RITE*," " EN DI F LOADS 4 I F C N L M . N E . 0 ) THEN DO 2 7 0 1 = 1 , M I F C L M L C I ) . N E . 0 ) THEN J l = 3 * J J CI ) - 2 J2 = 3 * J J C D - I J 3 = 3 * J J CI ) K l = 3 * J K CI ) - 2 K2=$*JK C D - I K3 = 3 * J K C I ) A E C J I ) = AECJ1 ) - C X C I ) * A M L C 1 , I ) * CYC D * A M L C 2 , D AECJ2) = A E ( J 2 ) - C Y C D * A M L C 1 , D - C X C D * A M L C ? , D A E (J3)=A E C J3)-A M L(3,I) AECK1) = A E C K 1 ) - C X C D * A M L C 4 , D + C Y C D * A M L C 5 , D A E C K 2 ) * A E C K 2 ) - C Y C D * A M L C 4 , D —C X C D * A M L C 5 , D AE(K3) = AECK3)-AMLC6,D ENDIF C ON T I N U E EN DI F DO 2 8 0 J = I , ND JR=IDCJ) AC C J R ) = A J CJ >* AEC J ) CON T I N U E BANSOL DO 4 3 0 1 = 1 , N J=I-N B tI I F C I . L E . NB) SJM = ACC I ) K I= I-I J=I 56 4?3.0m 4 ?4.non 4 25.000 426.000 427.000 4 28 . 0 0 0 429.000 450.000 431.000 432.000 433.000 4 34.000 435.000 436.000 437.000 438.000 439.000 440.000 441.000 442.000 443.000 444.000 445.000 446.000 447.000 448.000 449.000 450.000 451.000 452.000 453.000 454.000 4 55.000 4 56.000 457.000 458.000 4 59.000 460.000 461 . 0 0 0 462.000 463.000 464.000 465.000 466.000 467.000 468.000 469.000 470.000 471.000 4 72.000 473.000 474.000 475.000 476.000 477.000 478.000 479.000 480.000 481.000 482.000 483.000 440 603 430 450 470 60 4 460 C C C 290 15 14 700 I 7 I F ( J . G T . K D GOTO 4 0 3 03 4 4 0 K A = J , K l SUM=SUM-SFFCKA,I - K A + 1 ) = D F( KA) CON T I N U E OF(I)=SUM CO J T I N U E DO 4 5 0 1 = 1 , N O F ( I ) =O F ( I ) / S F F ( I , I ) CON T I N U E DO 4 6 0 1 1 = 1 , N I =N - I D I J=DN O -I I F ( J . G T . N) J=N SUM = DFC I ) K2=D1 I F ( K 2 . G T . J ) GOTO 6 0 4 DO 4 7 0 K A = K 2 , J SUM= S U M - S FF ( I , K A - D D = D F ( K A ) CON T I N U E O F d ) =SUM C ON T I N U E RESUL 4 J = N= I DO 2 9 0 K A = I ,NO JE=ND-KA=I I F C J R L ( J E ) . E l . 0 ) THEN J =J -I DJ(JE)=DF(J) ELSE OJ(JE)=O.O EN DI F C ON T I N U E W R I T E * , " J O I N T DISPLACEMENTS" WR I T E CI O8 , 1 5 ) FORMAT( 2 X , " J O I N T " , 7 X , " D J I " , 7 X , " D J 2 " , 7 X , " D J 3 " ) DO 3 0 0 J = D N J W R IT E ( 1 0 8 ,1 6 ) J ,D J ( 3 * J - 2 ) ,D J (3 * J- 1 ) ,D J ( 3 * J ) FORM AT!2X,I5,3F10.3> CON T I N U E W RITE*," " W R I T E * , ” MEMBER E N D - A C T I O N S " WR I T E ( I 0 8 > I 7 ) FORMAT ( 2 x , " MEMBER " , 6 X , " A I M 1 " , 7 X , " A M ? " , 7 X , " A M 3 " , 7 X , " AV/*' *7X ,"A M 5",7X,"4M 6") DO 3 1 0 I = D M Jl = 3*JJ ( D - 2 J2=3*JJ( I ) - I J 3 = 3 *J J ( I) Kl = 3 * J K ( I ) - 2 K 2 = 3 * JK ( I ) - I K 3=3*JK(I> S C M I =G * X I ( I ) / E L ( I ) SCM 2=4.0*E*YI(I ) /E L (I) S CM3 = 1 . 5 * S C M 2 / E L ( I ) SCM4=2.0«SCM3/EL(I> A M D ( I ) = S C M 1 * ( ( DJ ( J I ) - D J ( K D ) * C X ( I ) + ( OJ ( J 2 ) - D J ( K 2 ) ) ' A M D (2)=SC M 2*(-(O J(JD +0.5*D J ( K D ) * C Y ( I) +(D J (J 2 )= 0 .' **C X (I)>-SC M 3*(D J(J7)-D J(K 3>) AMD( 3) = S C M 3 * ( ( DJ ( J I ) = D J ( K D ) *C Y ( I ) - C DJ ( J 2 ) = D J ( K 2 ) ) . 57 4 8 4 . non 485.000 486.000 487.000 4 88.000 489.000 490.000 4 9 1 . 0 0 0 520 492.000 493.000 494.000 495.000 496.000 497.000 498.000 499.000 500.000 501.000 502.000 503.000 504.000 505.000 506.000 507.000 508.000 509.000 510.000 511 . 0 0 0 512.000 513.000 514.000 515.000 516.000 517.000 518.000 519.000 520.000 521 . 0 0 0 522.000 523.000 524.000 525.000 526.000 527.000 528.000 529."00 530.000 531.000 532.000 533.000 534.000 535.000 536.000 537.000 538.000 5 39.000 540.000 541.000 542.000 543.000 544.000 * + S C 3 4 * ( BJ <J 3 J - 0 J ( K 3 ) ) AMD ( 4 ) = - A M O d ) A M O ( 5 ) = S C M 2 * ( - ( 0 . 5 * O J ( J I ) + O J ( K 1 ) ) * c Y ( I ) + (Q ‘ *CX(I)>-SCM3+(0J(J3>-0J<K3>> A ,1 D ( 6 ) = - A M 0 ( 3 ) DO 3 2 0 J =1 ,MO A M ( J ) = A M L U , I ) +A M O ( J ) C ON T I N U E X F ( J R K J I ) . E 9 . I ) THEN 5 * O J ( J 2 ) + D J (K2 ) > A R (J1)=A R (J1)+C X(I)*AM D (1)-C Y(I)+A M D (2) EN DI F I F ( J R L ( J 2 ) . E I . I ) THEN A R (J2)=AR(J2)+CY(I)*AM D(1)+CX(I)*AM D(2) ENDIF I F ( J R L ( J 3 ) . E 3 . I ) THEN AR(J3)=AR(J3>+AMD(3) ENDIF I F ( J R L ( K I ) . E 3 . I ) THEN A R (K 1)=A R (<1)+C X (I)*A M D (4)-C Y (I)*A M 0(5) EN DI F I F ( J R L ( K 2 ) . E S . I ) THEN AR (K7)=AR (K2)+C Y(I)*AM 0(4)+C X(I)+AM D (5) ENDIF I F ( J R L ( K 3 ) • E 9 . I ) THEN AR(K3)=AR(<3)+AMD(5) EN DI F I 8 313 330 19 W R ITE (108,13)I,A M (1),A M (2),A M (3),A M (4),A M (5),A M (6) F O RMA T ( 2 X , I 5 , 6 F 1 0 . 3 ) CON T I N U E DO 3 3 0 J = 1 ,NO I F ( J R L C J ) . NE. 0 ) THEN A R (J)=A R (J)-AI(J)-A E (J) ENDIF C ON T I N U E W RITE*,” ” WRITE *, "SU PP ORT REACTIONS" W RITE(108,19) F0RM AT(2X,"JOINT” , 7 X , " ARI" , 7 X , " A R 2 " , 7 X , " A R 3 " ) DO 3 4 0 J = 1 , N J J l =3*J-2 J2=3*J-1 J 3= 3*J N1=JRL(J1)+JRL(J2)+JRL(J3) I F ( N I . N E . 3 ) THEN 20 340 C C 600 620 W R IT E (10 8,20 )J,A R ( J I ) , AR(J2),AR (J3) F0RM AT(2X,I5,3F10.3) ENOIF C ONT I NU E GOTO 6 2 0 U R I T E * , " S F F NOT P O S I T I V E D E F I N I T E " WR I T E * , " * * » * * * * * * * + * * * * * ♦ * , * , * * * * * * * * , „ * , „ » , , , , „ , , , , , ISN=ISN+! WR I T E * , " * * « * * * * * * * * * * * * * * * * * * * * * * * * * * * * , * * * * * , , W RITE*," I NEW PRESET G R I D " WRITE*, 2 CHANGE I N PRESET G R I D " W RITE*," 3 NONPRESET G R I D " W RITE*," 0 STOP " W RITE*," W R I T E * , " I NPUT ONE OF THE ABOVE NUMBERS TO C O N T I N U E " 58 545.000 546.000 547.000 548.000 549.000 550.000 551.000 552.000 553.000 554.000 5 55 . 0 0 0 556.000 557.000 558.000 559.000 560.000 561.000 562.000 563.000 564.000 565.000 566.000 567.000 568.000 569.000 570.000 571.000 572.000 573.000 574.000 575.000 576.000 577.000 578.000 579.000 580.000 581.000 582.000 583.000 584.000 585.000 586.000 587.000 588.000 529.000 590.000 591.000 592.000 593.000 594.000 595.000 596.000 597.000 598.000 5 9 9 . COO 600.000 601.000 602.000 603.000 604.000 605.000 650 W R ITE*," * * * * + * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * , , W RITE*," * * * * * * * * * * * * * * * * * * * * * » * * * * * * * * * * , * * * * * * * * * * * * * * , * , * * * * . , I N P U T NEW I CHNGE=O I F I N E W . E Q . 0) GOTO 8 0 0 I F I N E W . E Q . 3 ) GOTO 6 3 0 I F t N E W . E Q . I ) GOTO 6 4 0 ICHNGE=ICHNGEtI W RITE*,” * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * W R I T E * , " I NUNHER OF S T R I N G E R S " WRITE*, LENGTH OF S T R I N G E R S " WRITE*, SPACI NG OF S T R I N G E R S " WRITE*, DEPTH AND WI DTH OF S T R I N G E R S " WRITE*, DEPTH AND WI DTH OF P L A N K " W RITE*, DEPTH AND WI DTH OF REDUCED S T R I N G E R " W RITE*, L OC A T I ON OF REDUCED S T R I N G E R " WRITE*, L OC A T I ON OF P L A N K " WRITE*, E AND G" W R I T E * , " 1 0 NUMBER OF LOADED J O I N T S " W R I T E * , " 1 1 NUMBER OF LOADED MEMBERS" WR I T E * , " I 2 NUMBER OF R E S T R A I N T S " W R I T E * , " 1 3 NUMBER OF R E S T R A I N E D J O I N T S " WR I T E * , " O NO CHANGES' WRI T E* , " " W R I T E * , " I NPUT ONE OF THE ABOVE NUMBERS FOR CHANGES" W R IT E *,"***************************************************' W R ITE*," * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * * • I N P U T CHANGE I F I C H A N G E . E Q . I ) THEN W R I T E * , " I NPUT NUMBER OF S T R I N G E R S " I N P U T NST GOTO 6 5 0 EN DI F I F I C H A N G E . E Q . 2 ) THEN W R I T E * , " I NP UT LENGTH OF S T R I N G E R S " I N P U T STL GOTO 5 5 0 EN DI F I F t C H A N G E . E Q . 3 ) THEN W R I T E * , " I NPUT S PA CI NG OF S T R I N G E R S ' I N 3 UT STS GOTO 6 5 0 ENDIF I F I CHANGE . E Q . W R I T E * , " I NPUT I N P U T D S , RS GOTO 6 5 0 4 ) THEN DEPTH 0 , AND WI DTH B OF STRINGERS' 5 ) THEN DEPTH D # AND WI DTH B OF P L A NK' ENDIF I F I C H A N G E . EQ. W R I T E * , " I NPUT INPUT OP ,B ° GOTO 6 5 0 ENDI F IFtCHANGE .EQ. W R I T E * , " I NPUT I N P U T R OS, R9S GOTO 6 5 0 ENDI F I F I C HAN GE . E Q . W R I T E * , " I NPUT I N P U T RST 6 ) THEN D I ME N S I O N S 7 ) THEN L OC A T I ON OF OF REDUCED REDUCED STR IN GE R, STRINGER, D AND B " S T RI NGE R U" 59 606.000 607.000 608.000 609.000 610.000 611.000 612.000 613.000 614.000 615.000 616.000 617.000 618.000 619.000 620.000 6 21 . 0 0 0 622.000 623.000 624.000 625.000 626.000 627.000 628.000 629.000 630.000 631.000 632.000 633.000 634.000 635.000 636.000 637.000 638.000 6 3 9 .0 0 0 "00 EOF h i t a f t e GOTO 4 5 0 ENDIF I F ( CHANGE . EQ• 8 ) THEN W R I T E * , " I N P U T L OC A T I ON OF PLANK AS FRACTI ON I NP U T LFP GOTO 6 5 0 ENDIF I F ( C H A N G E . EQ. 9 ) THEN W R I T E * , " I N P U T E AND G" INPUT E , G GOTO 6 5 0 EN DI F I F ( CHANGE . EQ. 1 0 ) THEN W R I T E * , " I NPUT NUMBER OF LOADED J O I N T S " I N P U T NLJ GOTO 6 5 0 EN DI F I F (CHANGE . EQ. 1 1 ) THEN W R I T E * , " I NPUT NUM8ER OF LOADED MEMBERS" I N P U T NLM GOTO 6 5 0 EN DI F I F ( CHANGE . EQ. 1 2 ) THEN W R I T E * , " I NPUT NUMBER OF R E S T R A I N T S " I N P U T NR GOTO 65 I ENDIF I F ( CHANGE . EQ. 1 3 ) THEN W H I T E * , " I NPUT NUMBER OF R E S T R A I N E D J O I N T S " I N P U T NRJ GOTO 6 5 0 ENDIF I F I C H A N G E . EQ. 0 ) GOTO 6 6 0 END r 4 3 9 . OOC * *E ! DON'T D R I i A L E DRI B8 LE OFF 3 1 1 : 4 6 06/1 2/35 S TRI NGFR LENGTH" 60 12:06 JUN DRIPfl LE ! GR ID 2 , FOR 12 '»5 ON D A L E N E . I C E FV093 11:59 PRESET GRI D 06/12/85 PRINT I , ELSE O ?1 INPUT ?7 MUNBER OF S T R I N GE R S INPUT ?25 . 0 LENGTH OF S T R I N GE R S INPUT SPACI NG OF S T R I N GE R S ?2. O INPUT DEPTH D, AND WI DTH O (in ) OF STRI NGERS O, AND WI DTH B (in ) OF PLANK ? 2 0 . 0»1 0 . 0 I N P U T DEPTH 7 3 . 0 . 12.0 I NPUT DIMENSIONS 7 1 8 . 0 . 10.0 INPUT OF REDUCED LOCATION OF REDUCED LOCATION OF PLANK, STRINGER, S TRINGER, D AND STRI NGER B (in ) NUMBER 74 INPUT 72 AS FRACTI ON OF I N P U T E AND G 71400.0,10.0 I N P U T NUMBER OF LOADED J O I N T S ( N L J ) , NUMBER OF LOADED MEMBERS ( N L M) 71,0 INPUT 728 NUMBER OF RESTRAINTS (NR) INPUT 714 NUMBER OF RESTRAINED JOINTS INPUT J O I N T R E ST RAI NT L I S T K , J P L ( 3 K - 2 ) » J R L ( 3 K - 1 ) , JRL(SK) 7 1 . 0 . 1.1 7 3 . 0 . 1.1 7 4 . 0 . 1.1 7 6 . 0 . 1.1 7 7 . 0 . 1.1 7 9 . 0 . 1.1 7 1 0 . 0 . 1.1 7 1 2 . 0 . 1 ,1 7 1 3 . 0 . 1 ,1 7 1 5 . 0 . 1.1 7 1 6 . 0 . 1.1 7 1 8 . 0 . 1.1 7 1 9 . 0 . 1 ,1 721 , 0 , 1 , 1 AND (NRJ) S TRI NGER LENGTH 61 input joint loads K , A J I 3 K - 2 ) ,AJ (TK-1 ) , A J ( 3 K ) ’ 11 , o . o , o . n , - i o . o * * , * * * * * * * * * * * * * * * * * * * * * « * * * * * * * * * * * * ‘ * * * * * * * “ ***** t**,****!*!***************************************** SPACING= P . 0 0 0 0 0 0 L Z D = I S M A I N STRI NGERS REDUCED STRI NGE RS PL A NK : : : I I . OCOOO * 1 0 . CCOOO * 3 . OOCOOO * STRUCTURAL PARAMETERS M N NJ NR 20 35 Pl 28 J O I N T COORDI NATES X JOINT . ono I .000 2 . 000 3 2 4 . OOO 4 74.000 5 74.000 6 43.000 7 48.000 3 48.000 9 77.000 I O 72.000 I 1 7 2 . OOO I 2 96.000 I 3 96.000 I 4 96.000 I 5 120.000 I 6 120.000 I 7 I PO.000 I 8 I 44.000 I 9 144.000 20 144.000 21 MEMPER I N F O R M A T I ON JJ JK MEMBER I P I 7 3 P P 5 3 4 5 4 5 6 5 5 3 6 7 8 7 R 9 8 O 3 I I 10 11 1O 11 12 11 11 14 I 2 13 14 I 3 14 15 I 4 14 17 I 5 16 17 16 17 18 I 7 17 PO 13 NRJ 14 20.00000 18.00000 1 2.00000 E 1400.00 G 10.00 Y . OCO I 5 0 . OCO 3 0 0 . CCO . OCO I 5 0 . CCO 3 0 0 . OCO .000 I 5 0 . OCO 3 0 0 . CCO . OCO I 5 0 . OCO 3 0 0 . OCO . OOO I 50.000 3 0 0 . OCO . OCO I 5 0 . OCO 300.000 . CCO I 50.000 3 0 0 . OCO XI 3333.333 3333.333 4 5 9 . CCO 3333.333 3333.333 4 5 9 . OCO 3333.333 3333.333 4 5 9 . OCO 6 3 6 0 . OCO 6360.000 4 5 9 . OCO 3333.333 3333.333 4 5 9 . OCO 3333.333 3333.333 4 5 9 . OCO YI 6666.667 6666.667 27.000 6666.667 6666.667 27.000 6666.667 6666.667 27.000 4360.000 4360.000 77.000 6666.667 6666.667 27.000 6666.667 6666.667 2 7 . 000 EL 150.000 150.000 24.000 150.000 150.000 24.000 150.000 150.000 24.000 150.000 150.000 24.000 I 50.000 150.000 24.000 150.000 150.000 24.000 CX .000 .0 00 1.000 .000 .000 1.000 .000 .000 1.000 .0 00 .000 1.000 .000 .0 00 1.000 .000 .000 I .000 CY I .000 I .0 0 0 .000 I .000 1.000 .000 I .000 1.000 .000 1.000 1.000 .0 0 0 1.000 1.000 .000 1.000 1.000 .000 62 19 20 19 20 20 21 J O I N T RESTRAINTS JOINT JRI J R2 I n I 3 n I 4 O I 6 O I 7 O I 9 O I I O O I O I 2 I I 3 O I I 5 O I I 6 O I I A O I I 9 n I 21 I O STRUCTURE NO. ML» NLJ I O ACTI ONS JO I N T I I 3333.333 3333.333 6666.667 6666.667 150.000 150.000 .000 .000 I .000 I .000 J R3 I I I I I I I I I I I I I I I AT J O I N T S AJI . OOO J O I N T D I S P L A C E ME N T S JOINT OJ 1 I . OOO 2 . OOO 3 . OOO 4 .000 5 .000 6 .000 7 -.002 3 . OOO 9 .002 I O -.004 11 . OOO I 2 .004 I 3 -.00? I 4 .000 15 .002 I 6 . OOO I 7 .000 I 3 . OOO I 9 . OOO 20 . OOO 21 . OOO MEMBER E N D - A C T I O N S ME MBER AMI I -.321 2 . 321 3 .000 4 -1.665 5 I .665 AJ 2 . CCO AJ 3 -10.000 DJ 2 . OCO .001 . OCO . OCO . 0C3 .000 . OCO . 0C9 . OCO . CCO . OCO . OCO . OCO -.0 09 . OCO . CCO - . 0C3 . CCO . OCO -.C C I . OCO DJ 3 .000 .016 .000 .000 -.019 .000 .000 -.1 66 .000 .000 -.362 .000 .000 -.166 .000 .000 -.019 .000 .000 .016 .000 A M2 . OCO 19.810 -.642 . OCO 23.555 AM3 -.132 .132 -.264 .157 -.157 AM4 .321 -.321 .000 1.665 -1.665 AM5 19.810 .000 6.9 81 -23.555 .000 AM6 .132 -.132 .2 64 -.157 .157 63 20 SUPPORT JOINT I 3 4 6 7 9 I O I 2 I 3 I 5 I 6 I 8 I 9 21 . non .000 . 000 . 000 5.091 -5.091 . OOQ I . 46 5 - I .465 . OOO .321 - . 321 REACTI ONS ARI . OOO . OOO . OOO . non . 00 0 . OOO . OOO . OOO . OOO .000 . OOO . OOO .000 .000 O 9 I O I I I 2 I 3 I 4 I 5 I 6 I 7 I 8 19 -10.311 . OCO 207.052 -19.295 . OCO 3 2 8 . 4C8 48.160 . OCO 207.052 -9.113 . OCO 23.555 -6.981 . OCO I 8 . non -5.091 5.091 .050 I .380 -1.380 2.811 2.189 -2.189 -2.811 1.380 - I .380 -.050 .157 -.157 .264 -.132 .132 AR2 -.321 -.321 - 1 .665 -1.665 -5.091 -5.091 . OCO . OCO 5.091 5.091 1.665 I .665 .321 .321 A R3 -.132 -.1 32 .157 .157 1.380 I .380 2.189 2.189 1.330 I .380 .157 .157 -.132 -.132 •o 8 7 .0 00 5.0 91 -5.091 9.113 -207.052 .000 .000 .000 .000 -48.160 -328.408 .0 00 19.295 -207.052 -5.091 5.091 .000 - I . 6 65 1.665 .0 00 -.321 .321 .000 .000 10.311 -23.555 .000 .6 42 19.810 .000 ****************************************************** ****************************************************** 1 2 T O NEW PRESET GRI D CHANGE I N P RESET NONPRESET GRI D STOP GRI D I N P U T ONE OF THE ADOVE KUHHE R S TO CONTI NUE ****************************************************** ****************************************************** ?0 *STOP* ! DONT D R I H P L E D R I B B L E OFF a 12:01 0 6 / 1 2/S 5 - e0 5 0 380 380 811 I 89 I 89 811 380 380 OSO - . I 57 I 57 - . 264 I 32 - . 132 -I I -2 -2 . . . . 2. 2. -I . I . MONTANA STATE UNIVERSITY LIBRARIES N378 Rl+85 c o b 2