Instructions for Back Calculations

advertisement

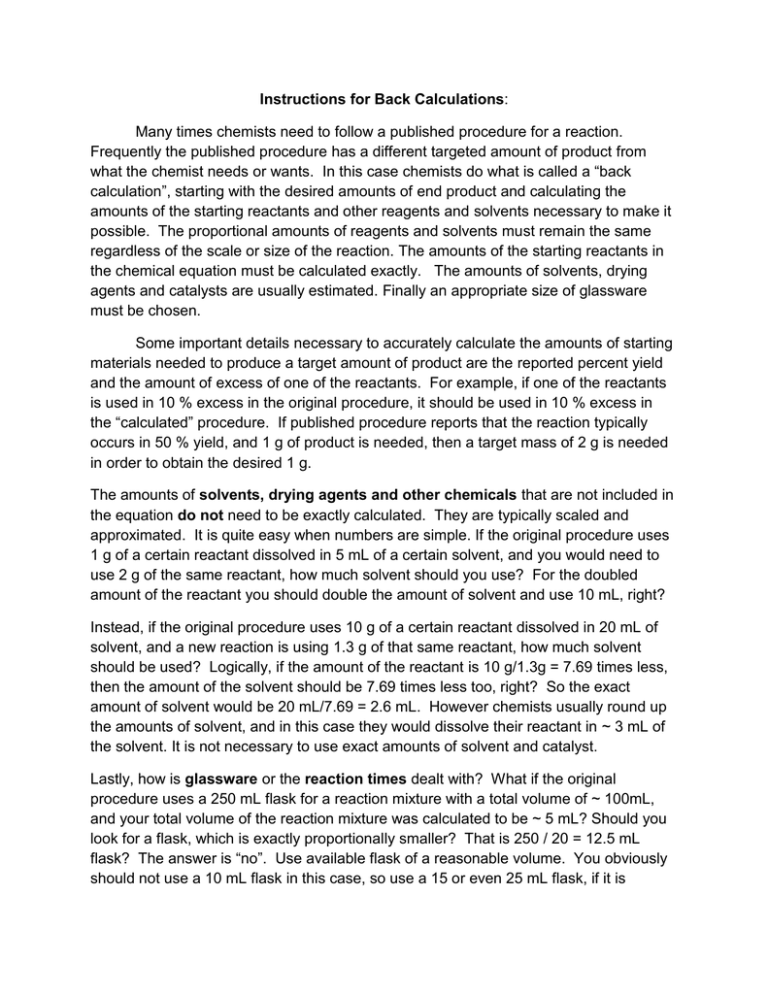

Instructions for Back Calculations: Many times chemists need to follow a published procedure for a reaction. Frequently the published procedure has a different targeted amount of product from what the chemist needs or wants. In this case chemists do what is called a “back calculation”, starting with the desired amounts of end product and calculating the amounts of the starting reactants and other reagents and solvents necessary to make it possible. The proportional amounts of reagents and solvents must remain the same regardless of the scale or size of the reaction. The amounts of the starting reactants in the chemical equation must be calculated exactly. The amounts of solvents, drying agents and catalysts are usually estimated. Finally an appropriate size of glassware must be chosen. Some important details necessary to accurately calculate the amounts of starting materials needed to produce a target amount of product are the reported percent yield and the amount of excess of one of the reactants. For example, if one of the reactants is used in 10 % excess in the original procedure, it should be used in 10 % excess in the “calculated” procedure. If published procedure reports that the reaction typically occurs in 50 % yield, and 1 g of product is needed, then a target mass of 2 g is needed in order to obtain the desired 1 g. The amounts of solvents, drying agents and other chemicals that are not included in the equation do not need to be exactly calculated. They are typically scaled and approximated. It is quite easy when numbers are simple. If the original procedure uses 1 g of a certain reactant dissolved in 5 mL of a certain solvent, and you would need to use 2 g of the same reactant, how much solvent should you use? For the doubled amount of the reactant you should double the amount of solvent and use 10 mL, right? Instead, if the original procedure uses 10 g of a certain reactant dissolved in 20 mL of solvent, and a new reaction is using 1.3 g of that same reactant, how much solvent should be used? Logically, if the amount of the reactant is 10 g/1.3g = 7.69 times less, then the amount of the solvent should be 7.69 times less too, right? So the exact amount of solvent would be 20 mL/7.69 = 2.6 mL. However chemists usually round up the amounts of solvent, and in this case they would dissolve their reactant in ~ 3 mL of the solvent. It is not necessary to use exact amounts of solvent and catalyst. Lastly, how is glassware or the reaction times dealt with? What if the original procedure uses a 250 mL flask for a reaction mixture with a total volume of ~ 100mL, and your total volume of the reaction mixture was calculated to be ~ 5 mL? Should you look for a flask, which is exactly proportionally smaller? That is 250 / 20 = 12.5 mL flask? The answer is “no”. Use available flask of a reasonable volume. You obviously should not use a 10 mL flask in this case, so use a 15 or even 25 mL flask, if it is available. However you do not want to use a 100 mL flask. Reaction times are usually kept the same. Common size (round bottom) reaction flasks are 5 mL, 10 mL, 25 mL, 50 mL, 100 mL, 250 mL, 500 mL, 1 L, 2L and 5 L. For safety one always wants 1/3 to ½ of ‘free space’ in flask. If the total volume of a reaction is 85 mL, do not use a 100 mL flask as it would be 85% full. Instead use a 250 mL flask and have it about 30 % full. An esterification reaction will be used to learn how to do a “back calculation”. Glucose will be reacted with five equivalents of benzoyl chloride to produce 1,2,3,4,6penta-O-benzoyl glucopyranose. The reaction and procedure was taken from Vogel.i m.wt. = 180.16 g/mol m.p.= 86°C d= 1.5622 g/mL m.wt.=140.57 g/mol b.p.= 197.2°C d= 1.212 g/mL m.wt.= 385.4 g/mol m.p.= 184-186°C []=+184.4 In a 1-litre 3 –necked round bottom flask fitted with a mechanical stirrer, a calcium chloride guard tube, a 250-mL dripping funnel and a thermometer, place 126 mL of dry pyridine and 105 of dry dichloromethane. Cool the flask well in an ice-salt bath and add from the dropping funnel, with stirring a previously prepared and cooled solution of 174 g (144 mL, 1.5 mol) of benzoyl chloride in 144 mL of dry dichloromethane. Remove the dropping funnel and add 50 g (0.28 mol) of dry powdered a-D-glucose portionwise to the vigorously stirred material at a rate which maintains the temperature below 10°C. Allow the pink-coloured solution to stir at 0°C for 24 hours. The yield is 77%. Start with a balanced reaction equation and collect important information about your reactants and products. You may see some information that might not be necessary for your calculation, like Bp or Mp or [], but it is essential for safety considerations or just to know more about your reactants and products. Above the arrow you notice C5H5N, this is pyridine which is a catalyst. Below the arrow is CH2Cl2, this is dichloromethane (also known as methylene chloride) which is the solvent. When performing “back calculations” we first calculate the exact amounts of main reactants from the equation, then we estimate the amounts of solvents, catalysts and/or other reagents. As a first step, carefully re-read the balanced equation and the detailed procedure. (For your 2240L assignment, you will use the procedure published in the lab manual.) First Determine the limiting reagent and the amount of excess. The glucose is present in 0.28 mol. For a perfectly balanced stoichiometry the benzoyl chloride must be present with 5 molar equivalents or 5.0 X 0.28 = 1.4 mol. The benzoyl chloride is present as 1.5 mol, so a 0.1 mol excess or 0.1/1.4 x100% = 7% excess. Therefore the glucose is the limiting reagent. (For your 2240L assignment, you will be told the limiting reagent.) Second, From your desired amount of material determine the targeted amount. If the desired amount of product is 4 grams, should 4.0 grams be targeted? Yes only if the yield were 100%. Since the procedure states a 77% yield, if 4.0 g were targeted only about 3.1 g would be formed. Instead target a “theoretical” amount of 4.0 g/0.77 = 5.2 g of the product in order to get the amount you want. Start a ‘back calculation’ with the last calculation you do when determining percent yield. 𝐴𝑐𝑡𝑢𝑎𝑙 𝑚𝑎𝑠𝑠 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 𝑝𝑒𝑟𝑐𝑒𝑛𝑡_𝑦𝑖𝑒𝑙𝑑 = 𝑡ℎ𝑒𝑜𝑟𝑒𝑡𝑖𝑐𝑎𝑙_max _𝑚𝑎𝑠𝑠_𝑝𝑟𝑜𝑑𝑢𝑐𝑡 𝑥100% or rearranging to 𝑡ℎ𝑒𝑜𝑟𝑒𝑡𝑖𝑐𝑎𝑙 𝑚𝑎𝑥 𝑚𝑎𝑠𝑠 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 = 𝐴𝑐𝑡𝑢𝑎𝑙 𝑚𝑎𝑠𝑠 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 4.0𝑔 𝑥100% = 100% 𝑝𝑒𝑟𝑐𝑒𝑛𝑡 𝑦𝑖𝑒𝑙𝑑 77% = 5.2 𝑔 𝑝𝑟𝑜𝑑 Now you perform all of your calculations to target 5.2 g of the product. Third: Determine the amounts of each main reactant necessary. From the targeted amount of product, determine the amounts (in grams or milliliters) of each of the reactants. One can simply perform dimensional analysis ‘backwards’ to determine these amounts. The glucose is a solid, so this should be determined in grams. Begin with target amount of product. 5.2 𝑔 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 𝑥 1 𝑚𝑜𝑙 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 1𝑚𝑜𝑙 𝑔𝑙𝑢𝑐𝑜𝑠𝑒 180.16 𝑔 𝑔𝑙𝑢𝑐𝑜𝑠𝑒 𝑥 𝑥 = 2.4 𝑔 𝑔𝑙𝑢𝑐𝑜𝑠𝑒 385.4𝑔 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 1𝑚𝑜𝑙 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 1 𝑚𝑜𝑙 𝑔𝑙𝑢𝑐𝑜𝑠𝑒 The benzoyl chloride (BzCl) is a liquid, so this should be determined in milliliters. 5.2 𝑔 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 1 𝑚𝑜𝑙 𝑝𝑟𝑜𝑑 5 𝑚𝑜𝑙 𝐵𝑧𝐶𝑙 140.57 𝑔 𝐵𝑧𝐶𝑙 1 𝑚𝐿 𝐵𝑧𝐶𝑙 𝑥 𝑥 𝑥 𝑥 = 7.8 𝑚𝐿 𝐵𝑧𝐶𝑙 385𝑔 𝑝𝑟𝑜𝑑 1𝑚𝑜𝑙 𝑝𝑟𝑜𝑑 1 𝑚𝑜𝑙 𝐵𝑧𝐶𝑙 1.212𝑔 𝐵𝑧𝐶𝑙 However, we need to add a 7.0 % excess on top of this amount, or 7.8 mL benzoyl x 0.070 = 0.55 mL The total volume of benzoyl chloride is 7.8 mL + 0.55 mL = 8.4 mL Alternatively, you can use 7% excess of the stoichiometric equivalent or 5.35 instead of 5.0 to come up with the same answer in one step. 5.2 𝑔 𝑝𝑟𝑜𝑑𝑢𝑐𝑡 1 𝑚𝑜𝑙 𝑝𝑟𝑜𝑑 5.35 𝑚𝑜𝑙 𝐵𝑧𝐶𝑙 140.57 𝑔 𝐵𝑧𝐶𝑙 1 𝑚𝐿 𝐵𝑧𝐶𝑙 𝑥 𝑥 𝑥 𝑥 = 8.4 𝑚𝐿 𝐵𝑧𝐶𝑙 385𝑔 𝑝𝑟𝑜𝑑 1𝑚𝑜𝑙 𝑝𝑟𝑜𝑑 1 𝑚𝑜𝑙 𝐵𝑧𝐶𝑙 1.212𝑔 𝐵𝑧𝐶𝑙 Forth: We need to estimate the amounts of the rest of the things used in the reaction such as catalyst and solvent. Since the procedure may use different excess amounts of benzoyl chloride, always use the limiting reagent to determine a scaling factor used to estimate the amounts of the other non-reagents such as solvent and catalyst. The written procedure uses 50 g of glucose, and you calculated using 2.4 g of glucose. It means that you should change all of the amounts of solvents and catalysts by the scaling factor of 2.4/50 = 0.048 ~0.050. Round scaling factor to a reasonable value. Use the scaling factor to determine amounts of other materials. The moles of each of these chemicals does not need to be calculated. Round up to nearest milliliter or gram. Based on the procedure: Use the scaling factor to scale solvents and catalysts. Procedure uses: You would need: 126 mL dry C5H5N 7 mL dry C5H5N 105 mL dry CH2Cl2 6 mL dry CH2Cl2 (105 mL x 0.050= 5.25 mL ~ 6 mL) 144 mL dry CH2Cl2 8 mL dry CH2Cl2 (144 mL x 0.050= 7.2 mL ~ 8 mL) (126 mL x 0.050= 6.3 mL ~ 7 mL) Note; if a molarity or purity is listed keep that constant. Do NOT scale molarity or concentration. I.e. 95% isopropanol, remains 95% isopropanol, 3.9 M remains 3.9 M.) Fifth. Finally, what size flask would be appropriate? The total volume of materials will be 2.4 g glucose +8.4 mL benzoyl chloride + 7 mL C5H5N + 6 mL CH2Cl2 + 8 mL CH2Cl2 (assuming the glucose has a density of ~1 g/mL) we will have 27.4 mL or about 28 mL of material. Remembering that ideally a reaction flask should be filled to a maximum level of ~ 2/3 full, obviously a 25 mL flask would be inappropriate. A 50 mL flask would be 28 mL/50mLx100%= 56% full. It would be safe to use a 50 mL or possibly even a 100 mL flask. The reaction time would remain the same, stir for 24 hours. Author: G. Goloverda Revised: S.L. Weaver, March 2015 i th Vogel’s Textbook of Practical Organic Chemistry, 5 Edition, Pearson, London, 1989 p646.